Water-sealing feeder

A technology of feeder and water seal, which is applied in the field of water-sealed feeder device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

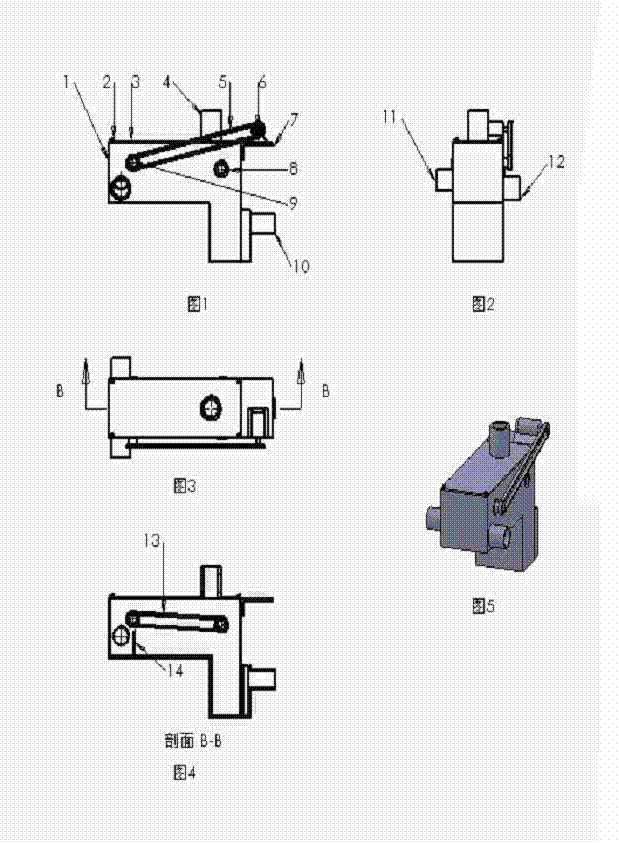

[0014] Such as figure 1 , As shown in Figure 4, make a frame 1 and install the drive shafts 8, 9. Press a motor bracket 7 on the right side of the frame 1, install the motor 6, and use the transmission belt 5 to connect with the transmission shaft 9. A connecting water outlet 10 is installed at the lower right of the rack 1, and an air outlet 12 and an air outlet 11 are connected to the front and rear on the left side of the rack 1. Install the inlet 4 on the upper cover 3 of the machine, then cover it on the frame 1, and fix it with screws 2.

[0015] As shown in Fig. 3, a chain conveyor 13 is connected to the drive shafts 8, 9 and a baffle 14 is installed on the bottom of the frame.

[0016] As shown in Figure 2, the air suction port 11 and the air supply port 10 of the water-sealed feeder must be connected with a closed circulation system for heat transfer and drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com