Tester for compressive strength of hollow glass beads

A hollow glass microsphere and compressive strength technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problem of easy flying, small particle size of hollow glass microspheres, and difficulty in measuring the compressive strength of hollow glass microspheres. and other problems to achieve the effect of eliminating data differences, intuitive and detailed data display, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

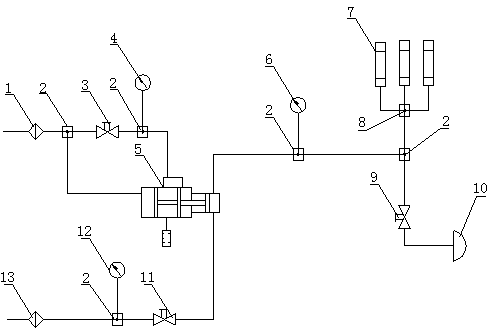

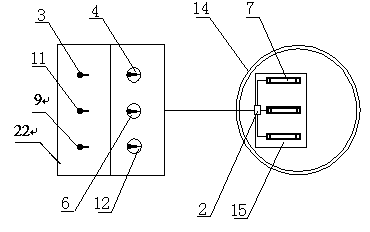

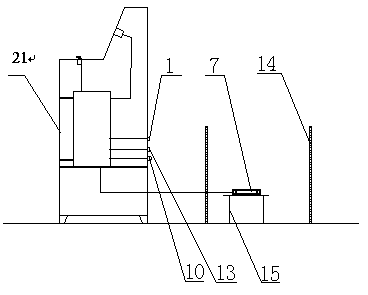

[0026] In order to further describe the present invention, the hollow glass microsphere compressive strength tester of the present invention will be further described below in conjunction with the accompanying drawings and examples.

[0027] Depend on figure 1 It can be seen from the schematic diagram of the hollow glass microsphere compressive strength tester of the present invention that it is formed by connecting a pressurized part and a high-pressure test part through pipelines. The boosting part is composed of air compressor 1, compressed air control valve 3, compressed air pressure gauge 4, booster pump 5, nitrogen cylinder 13, nitrogen pressure gauge 12, nitrogen control valve 11, air compressor 1, compression The air control valve 3 and the compressed air pressure gauge 4 are sequentially connected to the booster pump 5 through the compressed air inlet pipe, and the nitrogen cylinder 13, the nitrogen pressure gauge 12, and the nitrogen control valve 11 are sequentially...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com