Follow-up distributed perturbation screen secondary speckle elimination device

A distributed and screen technology, applied in optical components, optics, instruments, etc., can solve the problems of serious light loss, complex structure, and high cost, and achieve the effects of low power consumption, small size, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

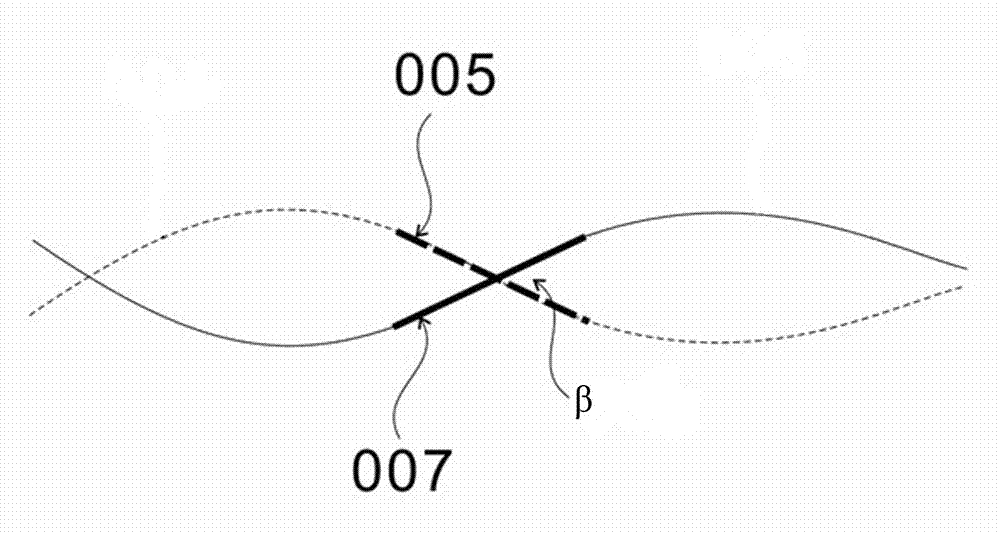

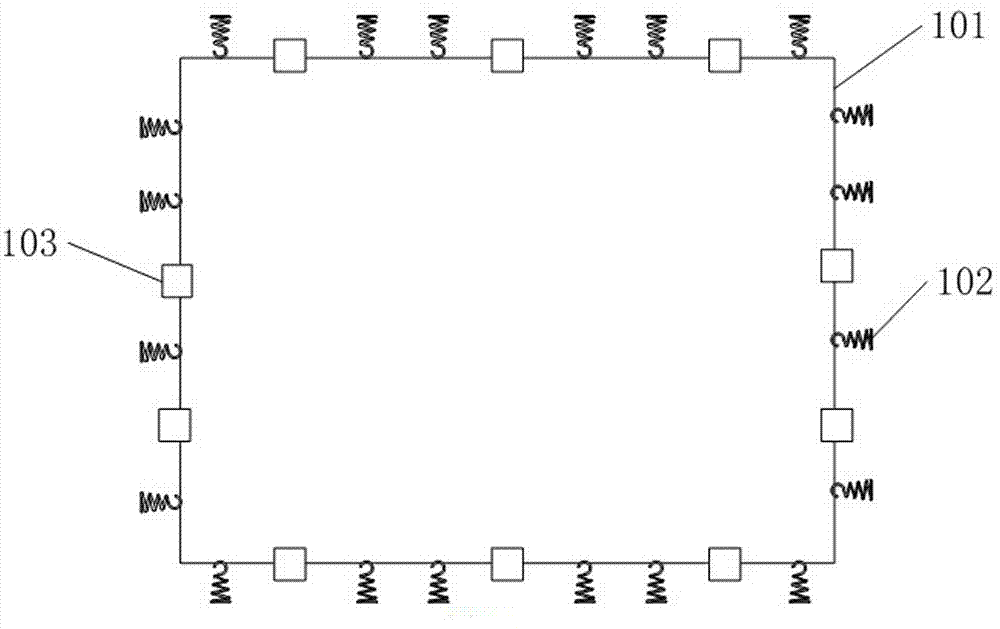

[0020] A secondary speckle removal device for a follow-up distributed perturbation screen, including a screen 101, an excitation source 103 with periodic or random vibration is arranged at the center of the screen 101, or is uniformly distributed around the screen 101 or within an area There are a plurality of excitation sources 103 with periodic or random vibration, and the amplitude A≥0.05mm when the excitation source 103 vibrates randomly, or the frequency f≥10Hz and amplitude A≥0.05mm when the excitation source 103 vibrates periodically.

[0021] During specific implementation, springs 102 are evenly distributed around the screen 101 (such as figure 2 shown), the screen is fixed and tensioned on the bracket by the spring, or the curtain is fixed by other means.

[0022] The excitation sources 103 are uniformly distributed around the scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com