Motor with oil storage function

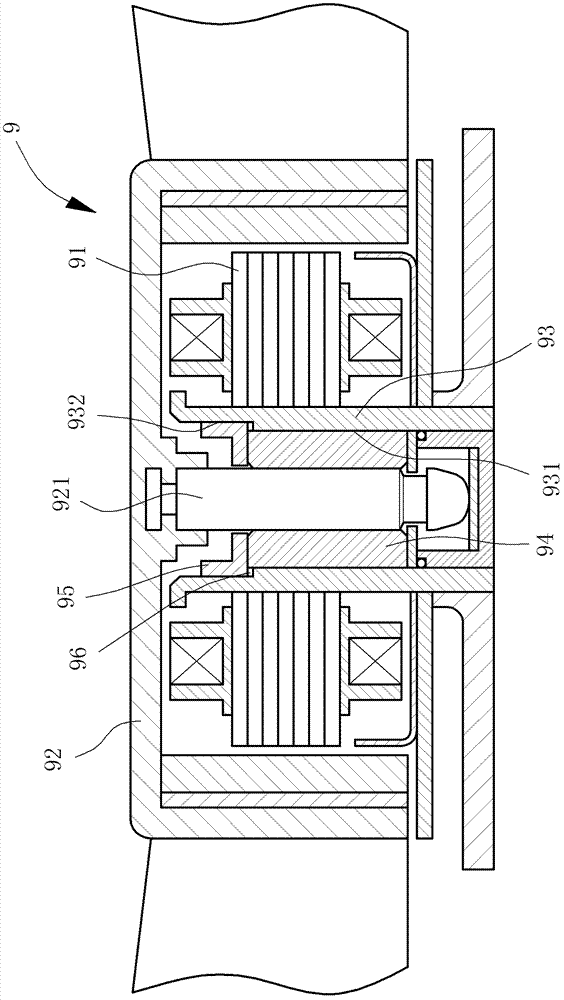

A motor and function technology, which is applied in the field of motors with oil storage function, can solve the problems of increasing the manufacturing cost of the existing motor 9, reducing the service life of the motor 9, and running unsmoothly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, as follows:

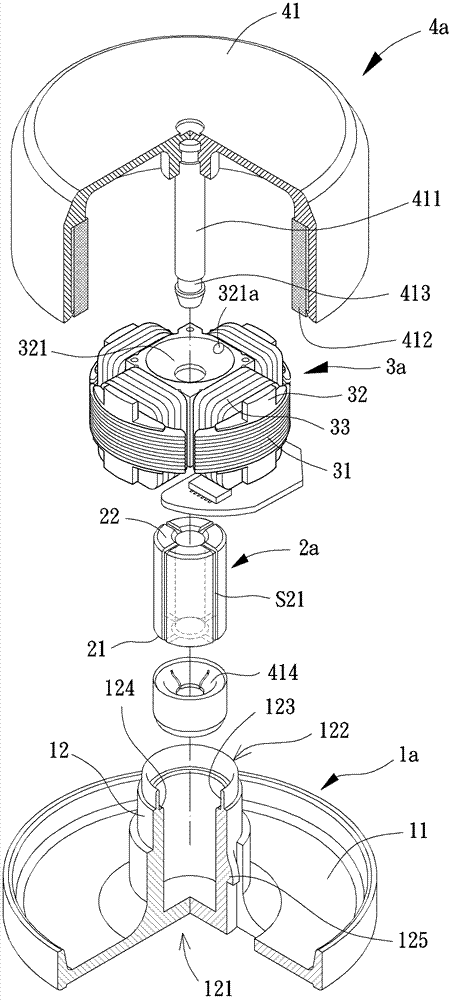

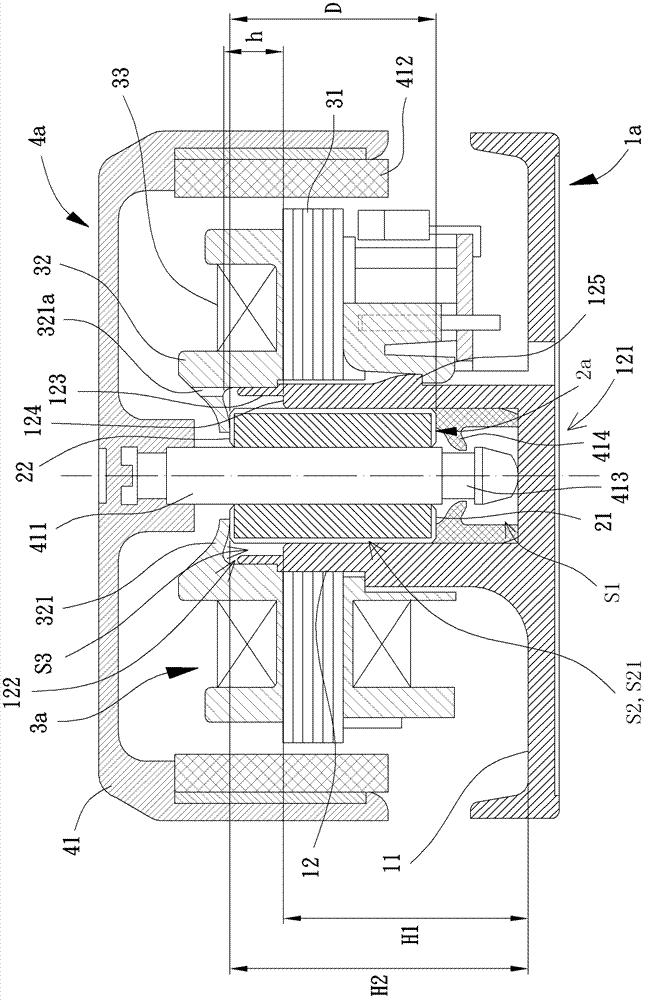

[0050] Please refer to figure 2 and 3 As shown, the motor with oil storage function according to the first embodiment of the present invention includes a base 1a, a bearing 2a, a stator assembly 3a and a rotor 4a. The base 1a can be accommodated and combined with the bearing 2a, the stator assembly 3a is combined with the base 1a, and the rotor 4a is rotatably combined with the bearing 2a.

[0051] The base 1a of the first embodiment of the present invention includes a base plate portion 11 and a shaft tube portion 12, and the shaft tube portion 12 is provided with a closed end 121 and an open end 122 opposite to each other, such as image 3 As shown, the closed end 121 of the shaft tube portion 12 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com