Factory large seedling raising room

A large-scale, steel-structured technology, applied in the field of seedling raising, can solve the problems of poor lighting effect of lighting roofs and water accumulation in irrigation, and achieve the effect of avoiding water accumulation in irrigation and strong lighting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

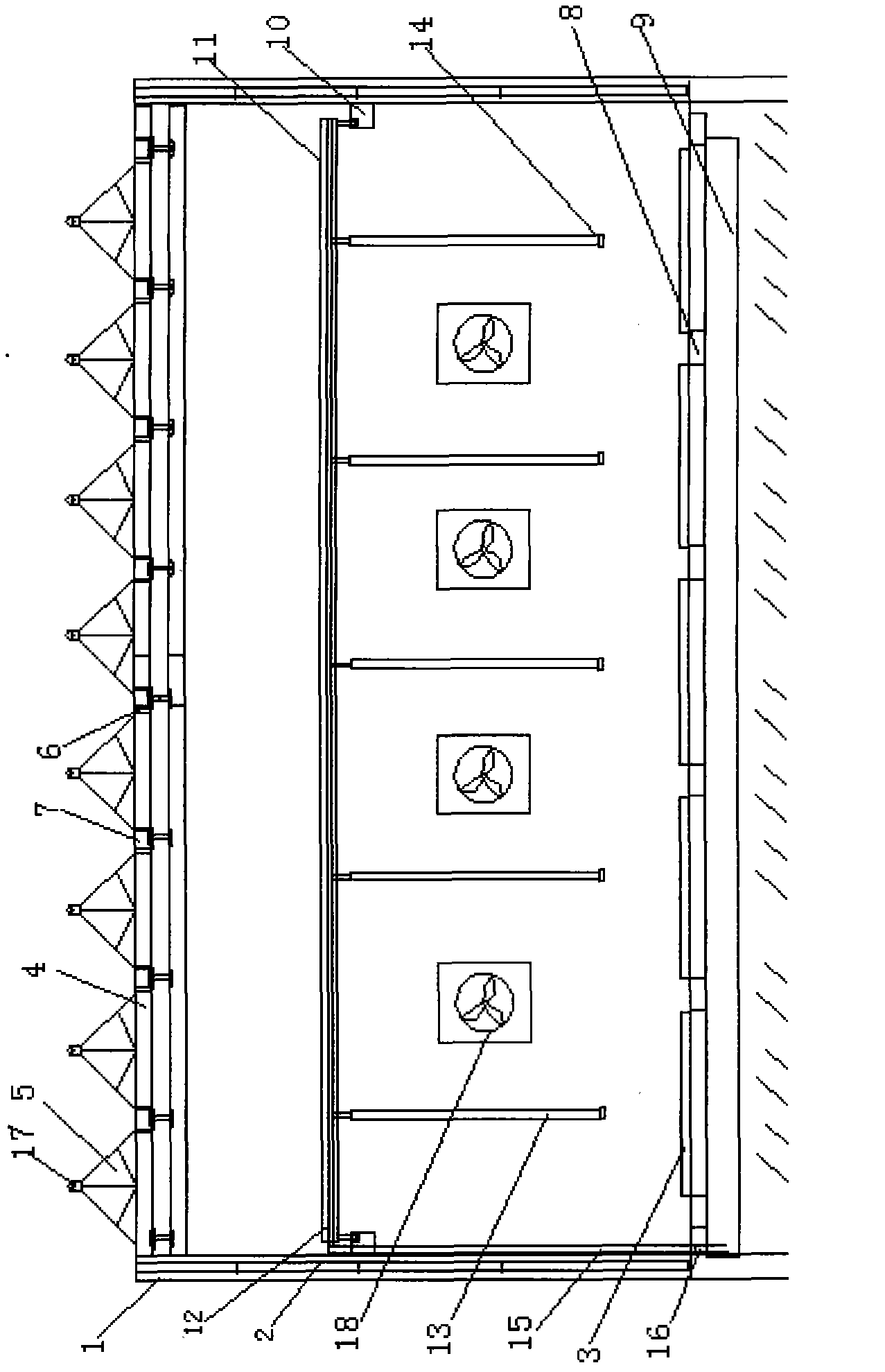

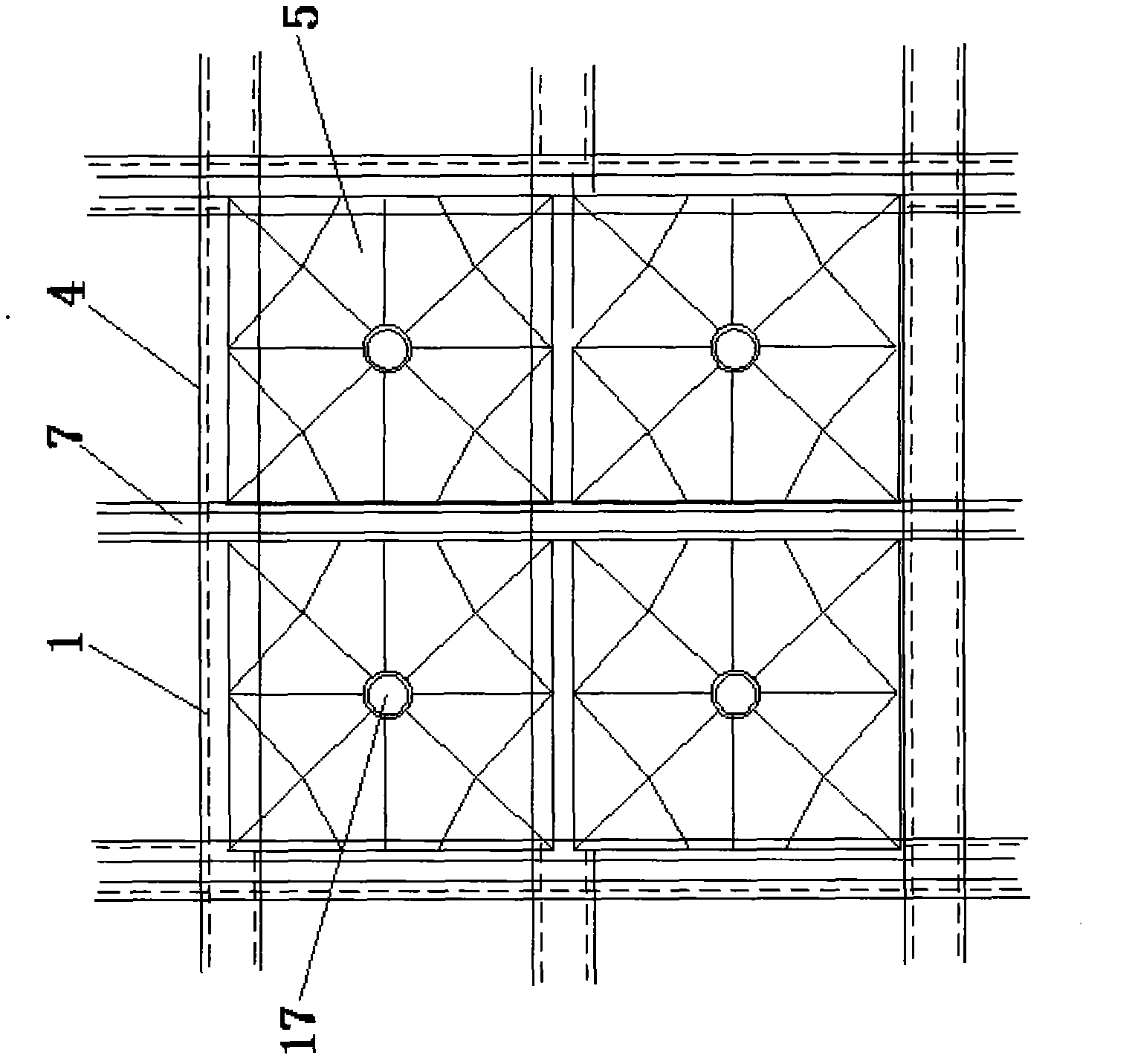

[0014] Example 1, such as figure 1 , 2 As shown, a factory large-scale seedling raising room, the seedling raising room is composed of a steel frame 1, transparent side walls around the steel frame 1, a lighting roof connected to the top of the steel frame, and an external structure arranged on the ground of the seedling raising room It is composed of a plurality of seedling cultivation areas 3 at the top, and the lighting roof is composed of a plurality of conical lighting bodies arranged in a matrix and a connecting chassis 4 connected to the bottom of each conical lighting body. The conical lighting body is composed of It consists of 4 triangular daylighting panels 5 and an exhaust device arranged on the top of each conical daylighting body, and a plurality of connecting fixtures 6 fixedly connected between the lower part of the connection chassis 4 and the top of the steel frame 1 are arranged, The upper surface of the connecting chassis 4 is provided with drainage shallo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com