Chained ingot receiving mechanism used for continuous casting production line of aluminum ingot

A foundry production line and chain technology, applied in foundry workshops, casting equipment, pig iron foundry workshops, etc., can solve the problems of high technical difficulty, damage to ingot casting machines, high equipment costs, etc., and achieve the effect of improving safety performance and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

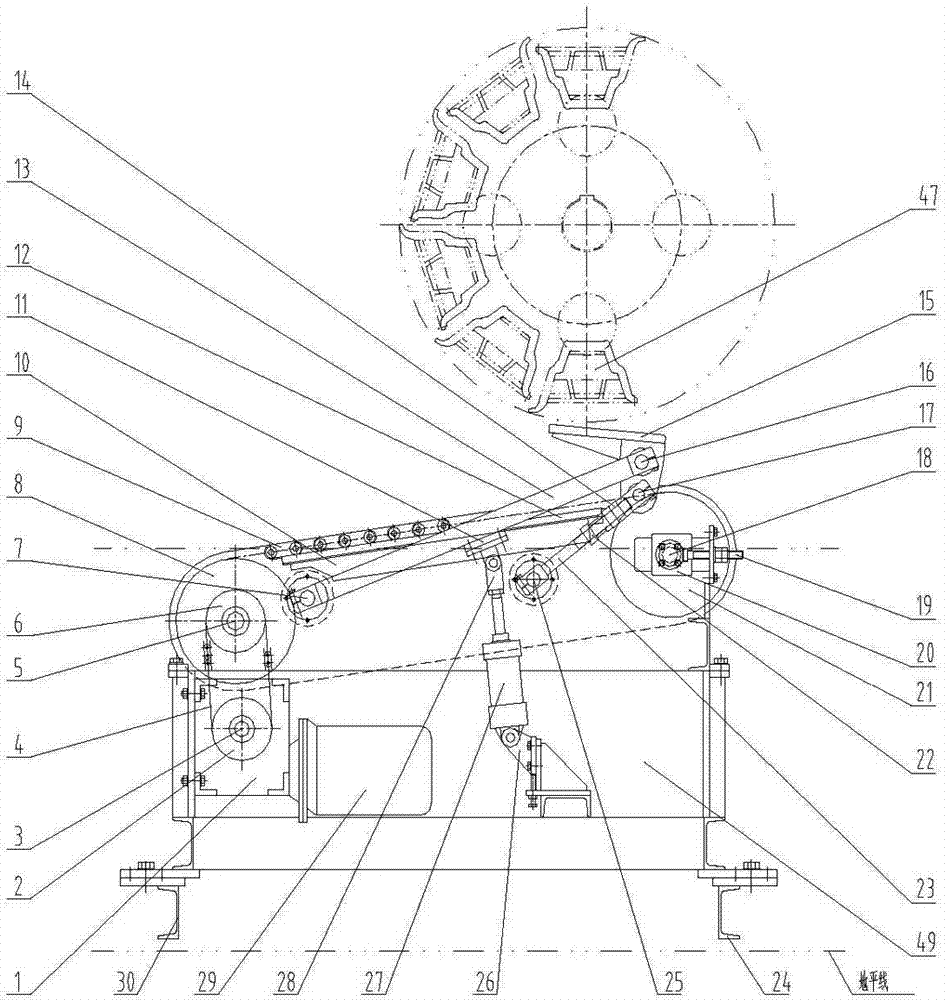

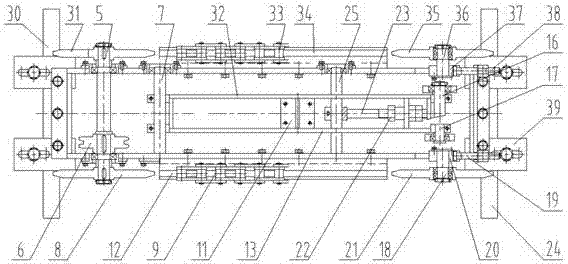

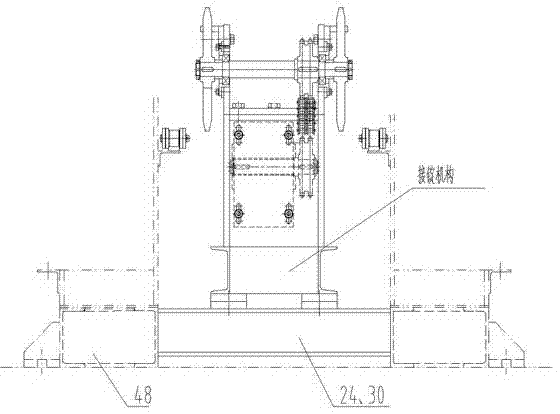

[0007] Such as figure 1 , figure 2 , image 3 As shown, the present invention is a chain-type ingot-connecting mechanism for an aluminum ingot continuous casting production line. The first channel steel 24 and the second channel steel 30 are welded on the inner side of the ingot-connecting end frame of the cold transport machine 48, and the machine of the ingot-connecting mechanism The frame 49 is fixed on the first channel steel 24 and the second channel steel 30 through a bolt group, the motor 29 and the reducer 1 are directly connected and fixed on the frame 49 through a bolt group, and the first double sprocket 2 is fixed on the reducer On the output shaft 3 of 1, the first double-link sprocket 2, the first chain 4 and the second double-link sprocket 6 form the first-stage chain transmission; the second double-link sprocket 6 and the first driving sprocket 8, the second Two driving sprockets 31 are fixed on the first shaft 5 by keys; bearings are arranged between the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com