Slot sliding key type simple self-locking inclined slide block pair device

A hole sliding key type, inclined slider technology, applied in the field of slotted hole sliding key type simple self-locking inclined slider pair device, can solve the problems of low efficiency, scrapped injection molding products, high cost, reduce cost, simplify structure, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

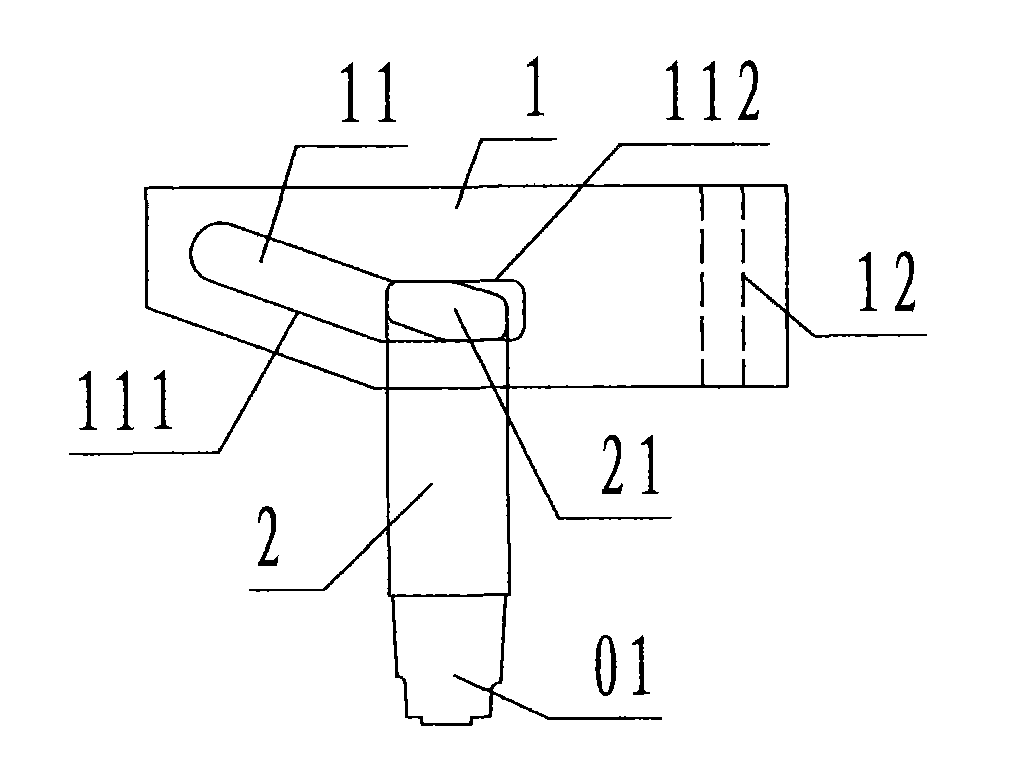

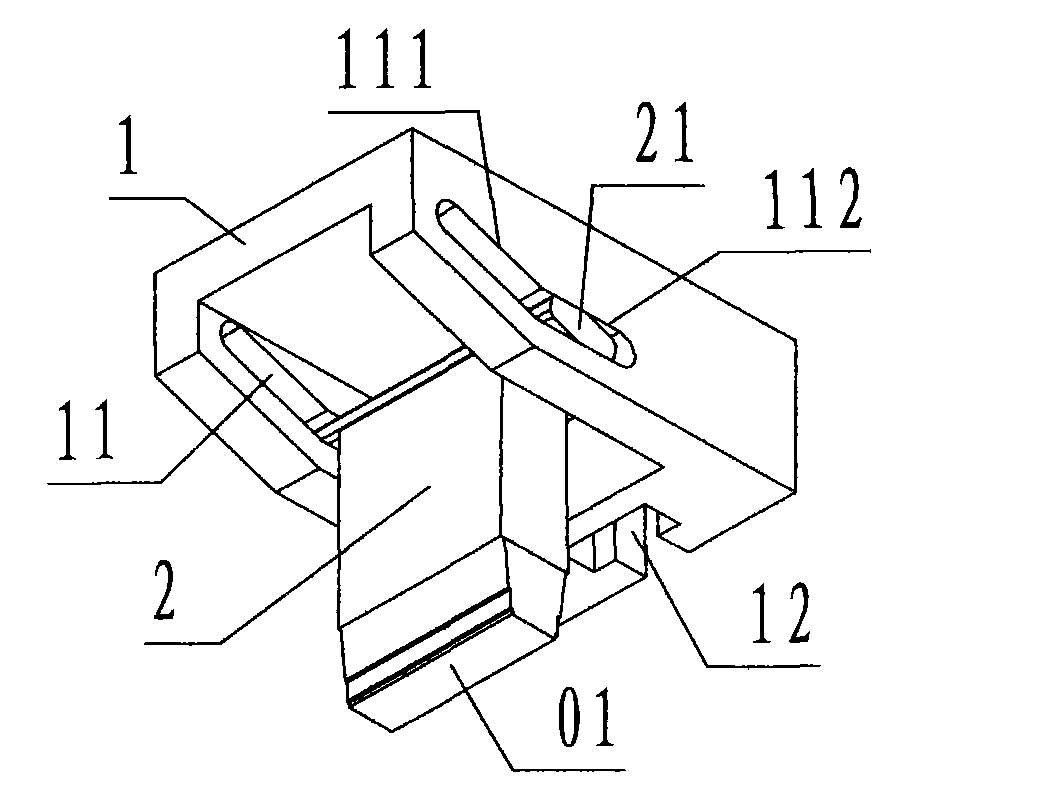

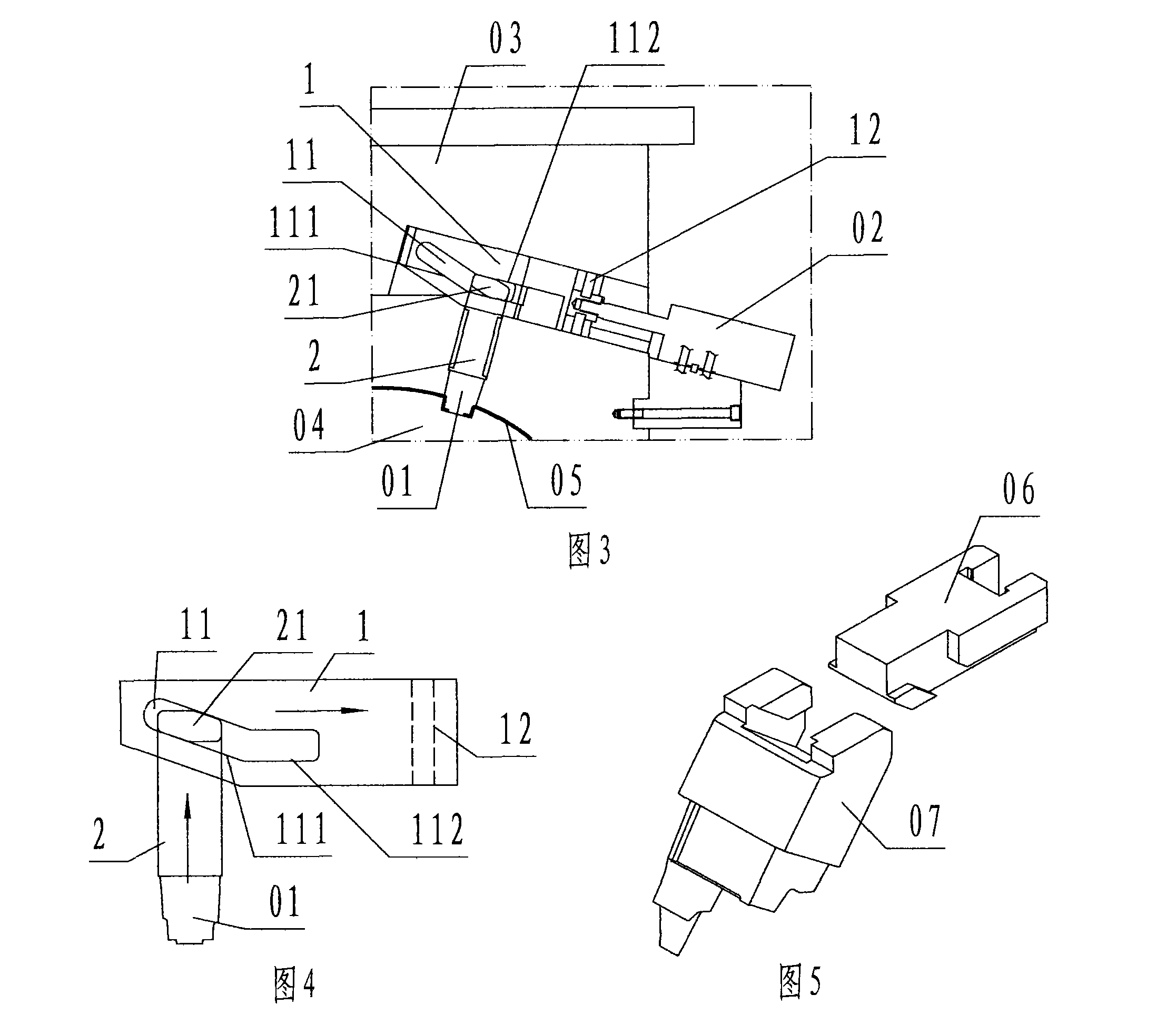

[0020] refer to Figure 1 to Figure 4 , a slotted key type simple self-locking oblique slider auxiliary device of the present invention, including a driving slider 1 and a driven slider 2, wherein: the driving slider 1 is a block steel formed by wedge-rectangular synthesis The material component, between the lower part of the left part of the active slider 1 and the left side of the active slider 1, there is a slope inclined to the left and upward called the wedge surface, and the lower part of the right part of the active slider 1 is the upper part of the active slider 1. Parallel planes are called straight planes; the bottom of the active slider 1 is provided with a groove with an open left end called a bottom groove, and the front and rear groove walls of the bottom groove are provided with folds parallel to the wedge surface and the straight plane. The curved and elongated through hole is called the chute hole 11. In the chute hole 11, the hole section corresponding to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com