Device capable of rapidly hoisting large-section sliding form

A large segment, sliding form technology, applied in the field preparation of formwork/formwork/working frame, building components, construction, etc., to achieve the effect of easy sliding, increasing the height of one pouring, and reducing the frictional resistance of sliding form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

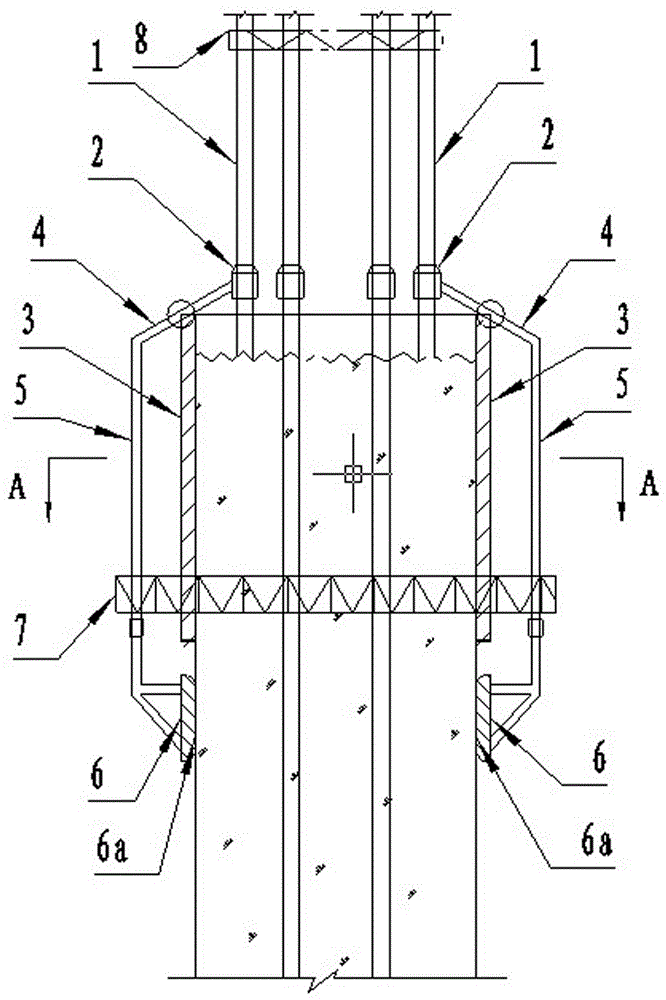

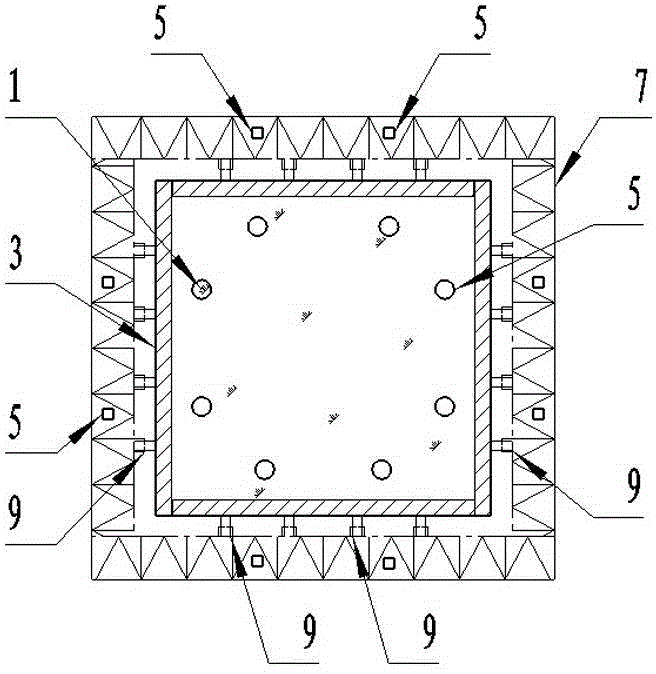

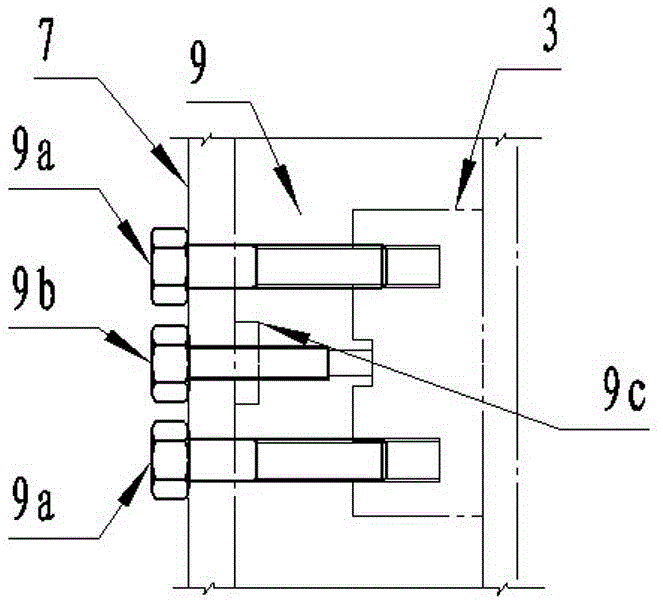

[0014] The rapid lifting large-segment sliding form device includes a formwork, a number of support rods 1, and sliding jacks 2 respectively set on each support rod 1. The formwork is composed of several unit formworks 3 that can be spliced with each other to enclose a complete set of grooves. Each sliding jack 2 is fixedly connected with a diagonal rod 4, the diagonal rod 4 is at an angle to the support rod 1 where the sliding jack 2 is located, and the two sides of the top of each unit template 3 are respectively hinged on two diagonal rods In the middle part of 4, the other end of each oblique rod 4 is suspended and fixedly connected with a positioning rod 5, and the positioning rod 5 located at the lower part of each unit template 3 can be detachably connected with a sliding shoe plate 6, and the sliding shoe plate 6 and the positioning rod 5 The connection point is higher than the bottom end of the unit formwork 3, and the flat surface 6a on the sliding part of each shoe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com