Multistage thermoelectric cooler parameter vacuum testing device

A technology of thermoelectric coolers and testing devices, which is applied in the direction of measuring devices, testing of machines/structural components, instruments, etc., and can solve problems such as easy condensation, inaccurate results, and difficulty in determining performance parameters of multi-stage thermoelectric coolers , to achieve the effects of high accuracy, multiple test parameters, and convenient procurement and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

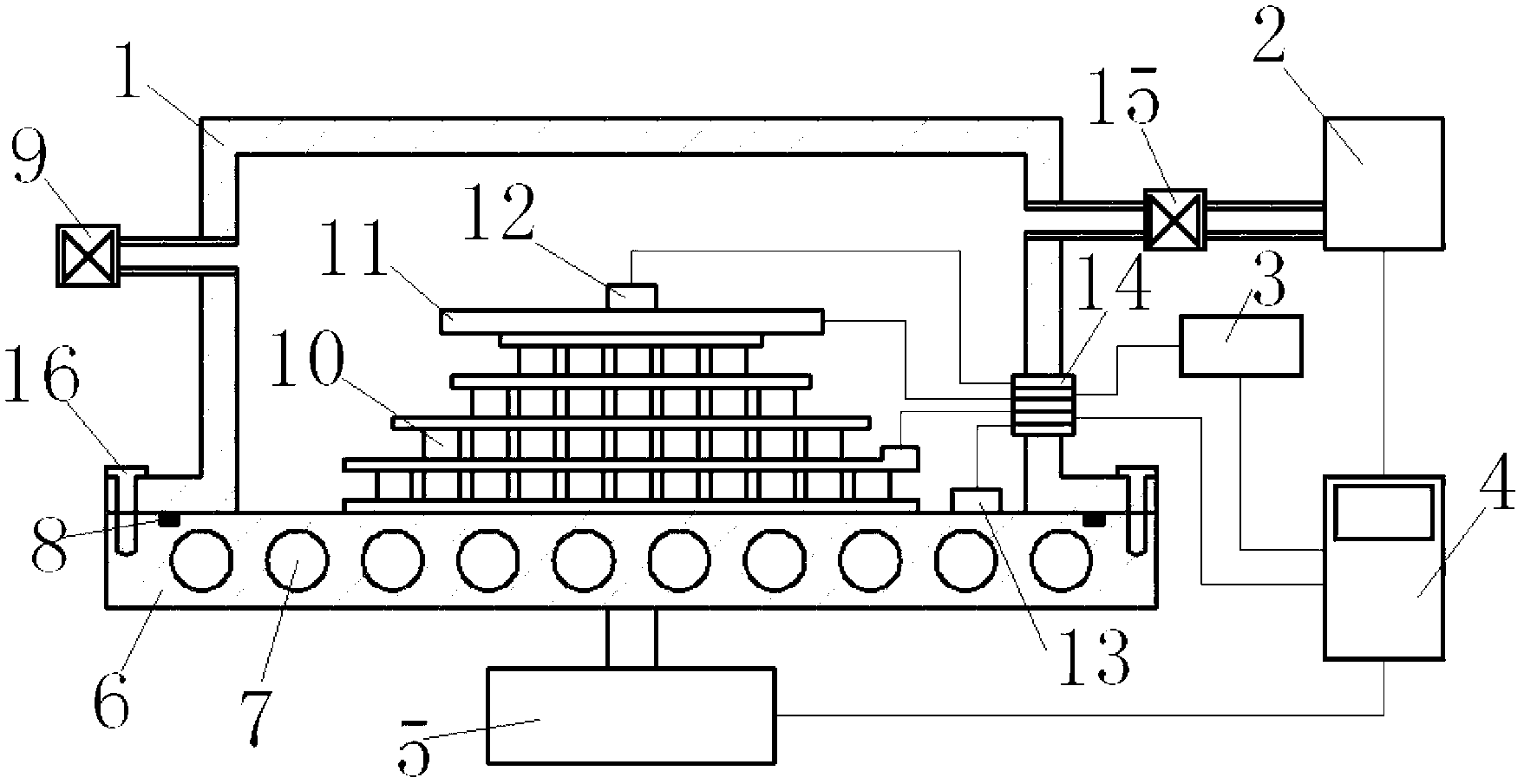

[0009] A multi-stage thermoelectric refrigerator parameter vacuum testing device, including a vacuum chamber 1, a vacuum pump 2, a water cooling head 6, a temperature-controlled cooling water circulation device 5, a heating resistance module 11, a cold-end temperature measuring resistance 13, and a hot-end temperature measuring resistance 12. DC power supply 3, data processing and display module 4. The vacuum cavity 1 is made of stainless steel, and the inner wall is polished. The left and right sides of the vacuum cavity 1 are respectively provided with a deflation valve 9 and a vacuum valve 15 , and the vacuum valve 15 is connected with the vacuum pump 2 . The vacuum cavity 1 and the water cooling head 6 are sealed by a vacuum rubber ring 8 and connecting screws 16 . A water-cooling conduit 7 is arranged inside the water-cooling head 6 and is connected to a temperature-controlled cooling water circulation device 5 . The thermoelectric cooler 10 is installed between the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com