Novel electronic product failure rate prediction correcting method

An electronic product and failure rate technology, applied in prediction, calculation, data processing applications, etc., can solve the problems of inability to reflect the impact of product failure rate, failure to provide solder joints and printed circuit board failure rate statistics, etc., to achieve accurate and reliable. predict results, eliminate experiments, predict the effects of simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] In the following, the present invention will be further described in detail in conjunction with the prediction process of a specific circuit module.

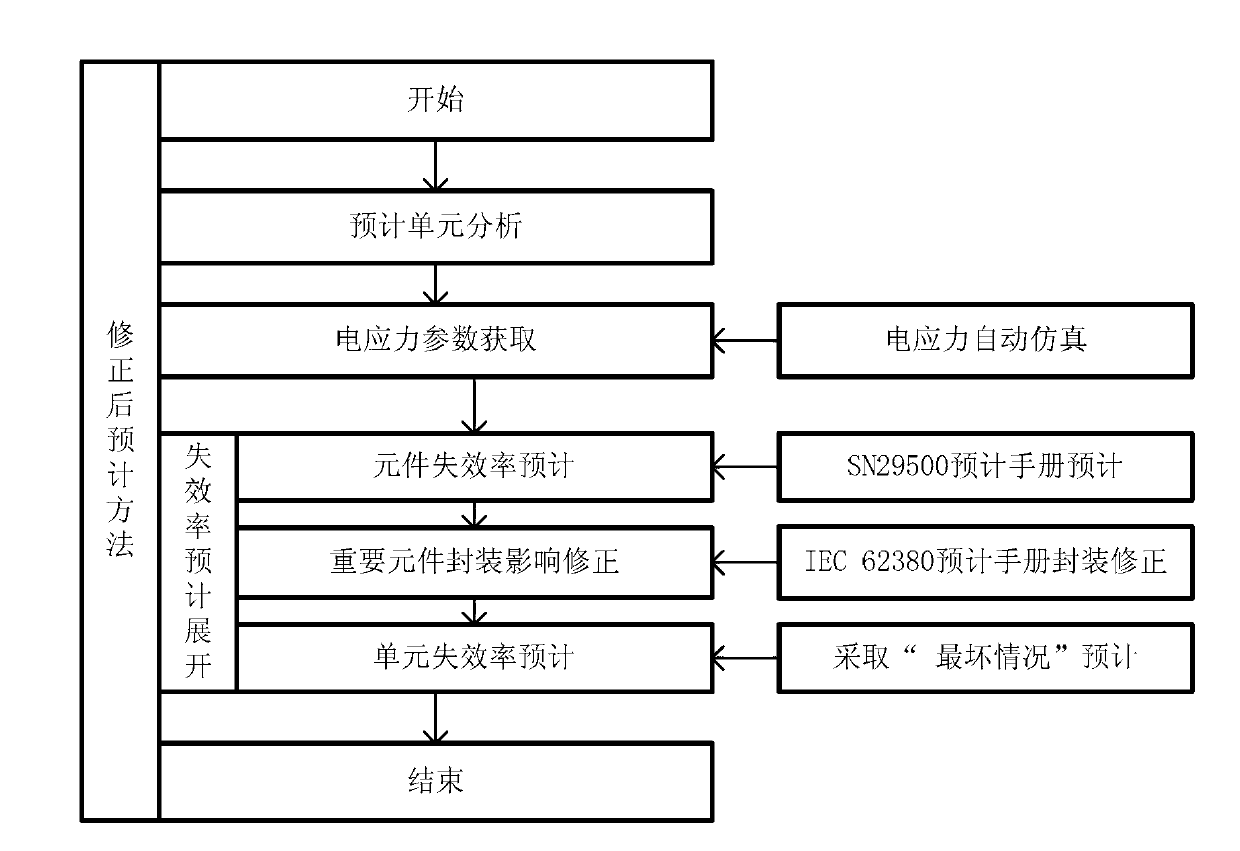

[0033] See figure 2 , a new method for predicting and correcting the failure rate of electronic products in the present invention, see figure 2 Shown, the specific implementation steps of its invention are as follows:

[0034] Step 1: Predicted unit composition analysis

[0035] In this embodiment, the prediction unit refers to a circuit module for prediction.

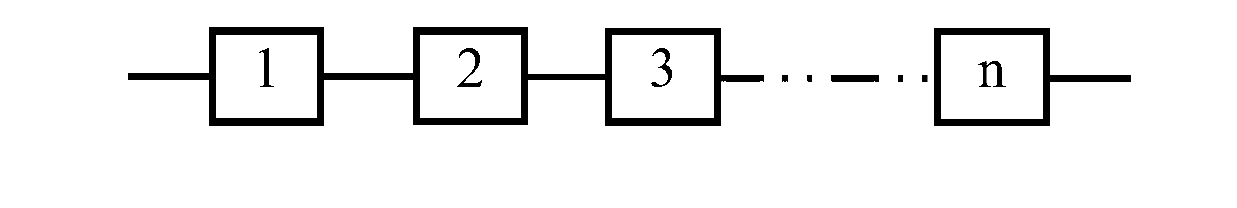

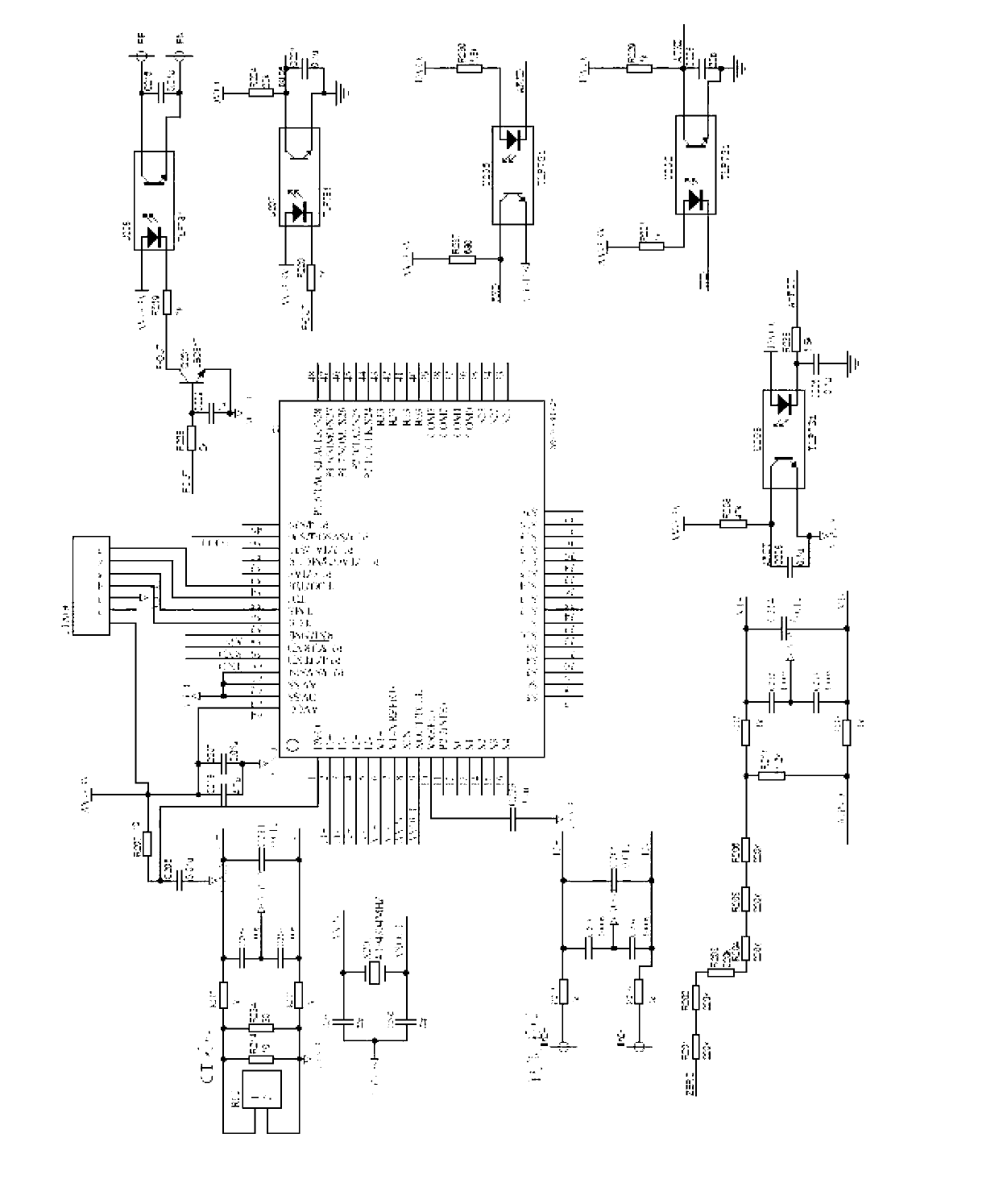

[0036] According to the physical object and schematic diagram of the circuit module, classify the components of the circuit module, obtain the components and the correlation between the components, and draw the composition structure diagram of the circuit module, among which, figure 1 It is a structural diagram of a circuit unit module of the present invention, and researches related information such as models, basic parameters and numbers of its constituent ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap