Cable connector manufacturing method for blasting operation

A technology for cable joints and production methods, which is applied to circuits, connections, electrical components, etc., can solve problems such as burnt cable caps, cables become brittle, and tensile strength is reduced, so as to avoid accidents and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The invention relates to blasting operations in the field of oil and gas field exploration and development, and relates to a manufacturing method for special cable joints for blasting operations.

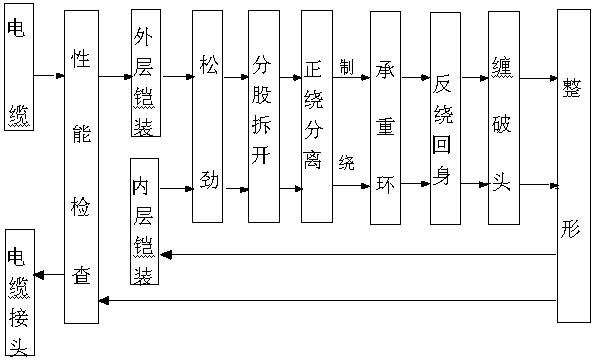

[0032] see figure 1 , the specific steps of a method for making a cable joint for blasting operations involved in the present invention are:

[0033] 1] Carry out a performance check on the cables to make sure that the on-off and insulation of the cables to be used meet the industrial requirements;

[0034] 2] Loosen the outer armor of the cable, disassemble the strands, and separate the forward winding to separate the outer armor from the cable; that is, loosen the outer armor of the cable and divide the outer armor into two strands in sequence Disassemble from the inner armor, and then combine the disassembled outer armor to separate the outer armor from the inner armor;

[0035] 3] Use a separate outer armor to wrap a circle at the root to form a load-bearing ring, and r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Insulation resistance | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com