Fuel injection valve for internal combustion engines

A technology of fuel injection valve and internal combustion engine, which is applied to fuel injection devices, internal combustion piston engines, combustion engines, etc., can solve problems such as unsolved fuel distribution problems, and achieve the effects of optimally controlling the amount of fuel and optimizing fuel atomization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

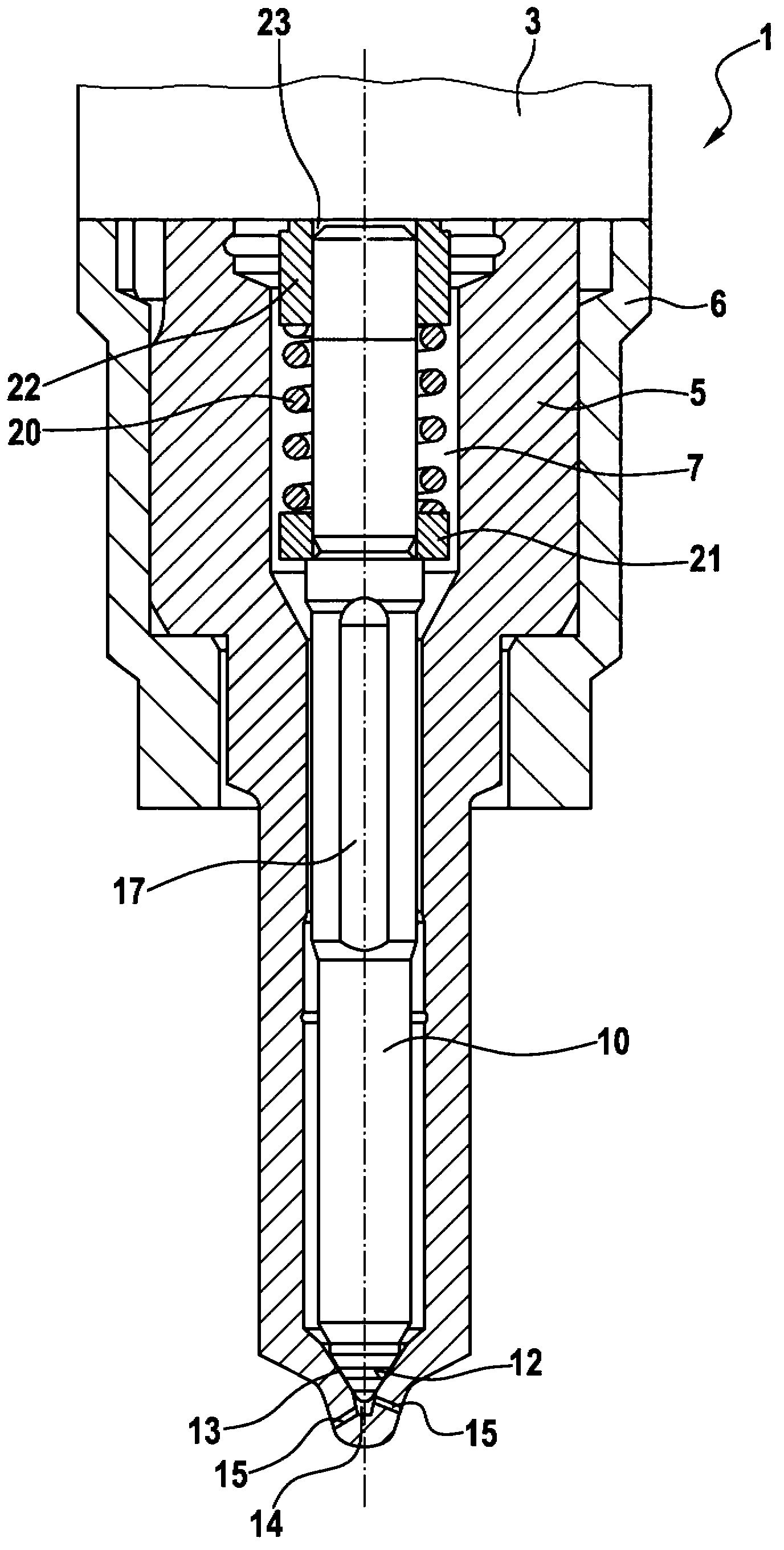

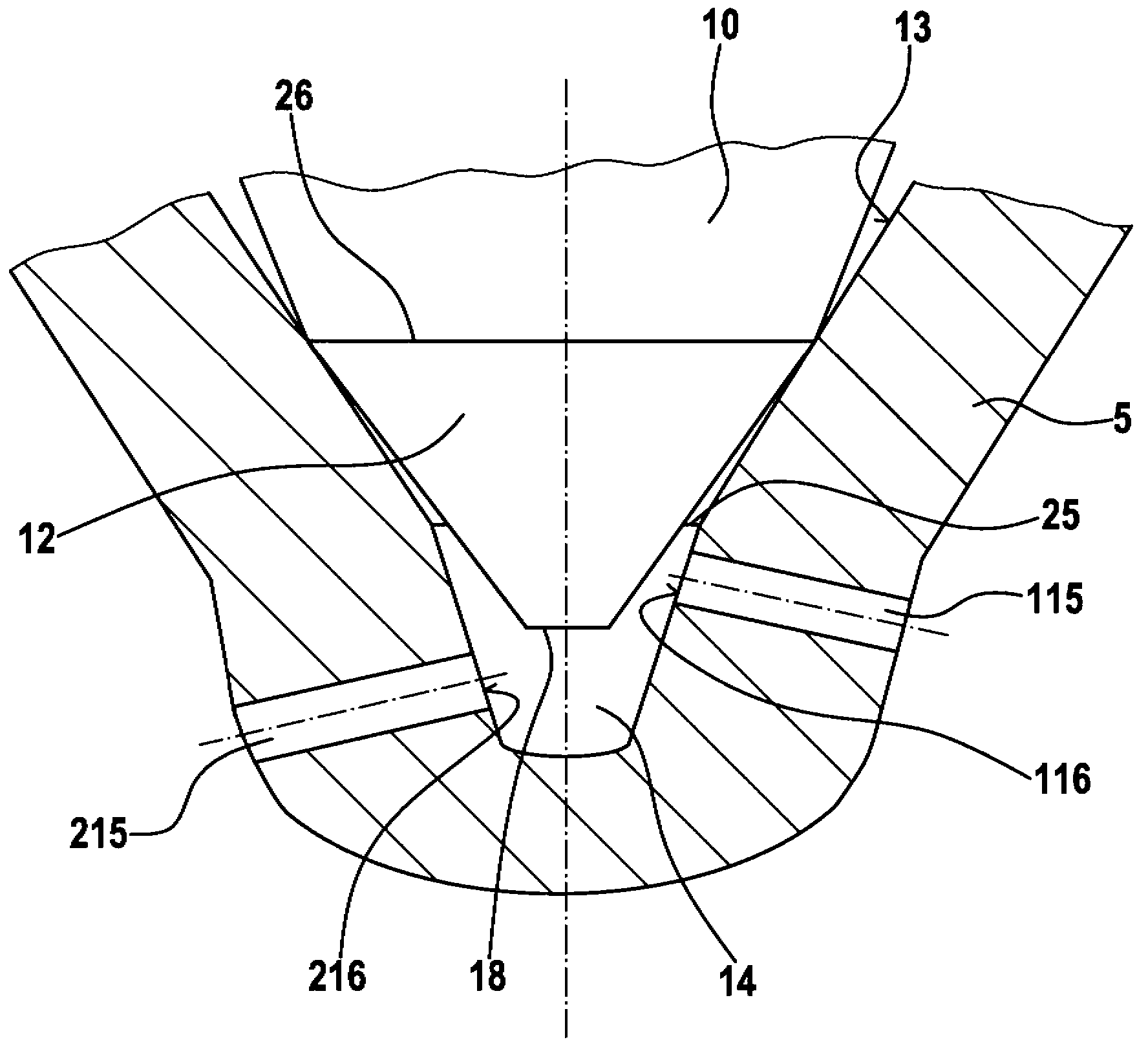

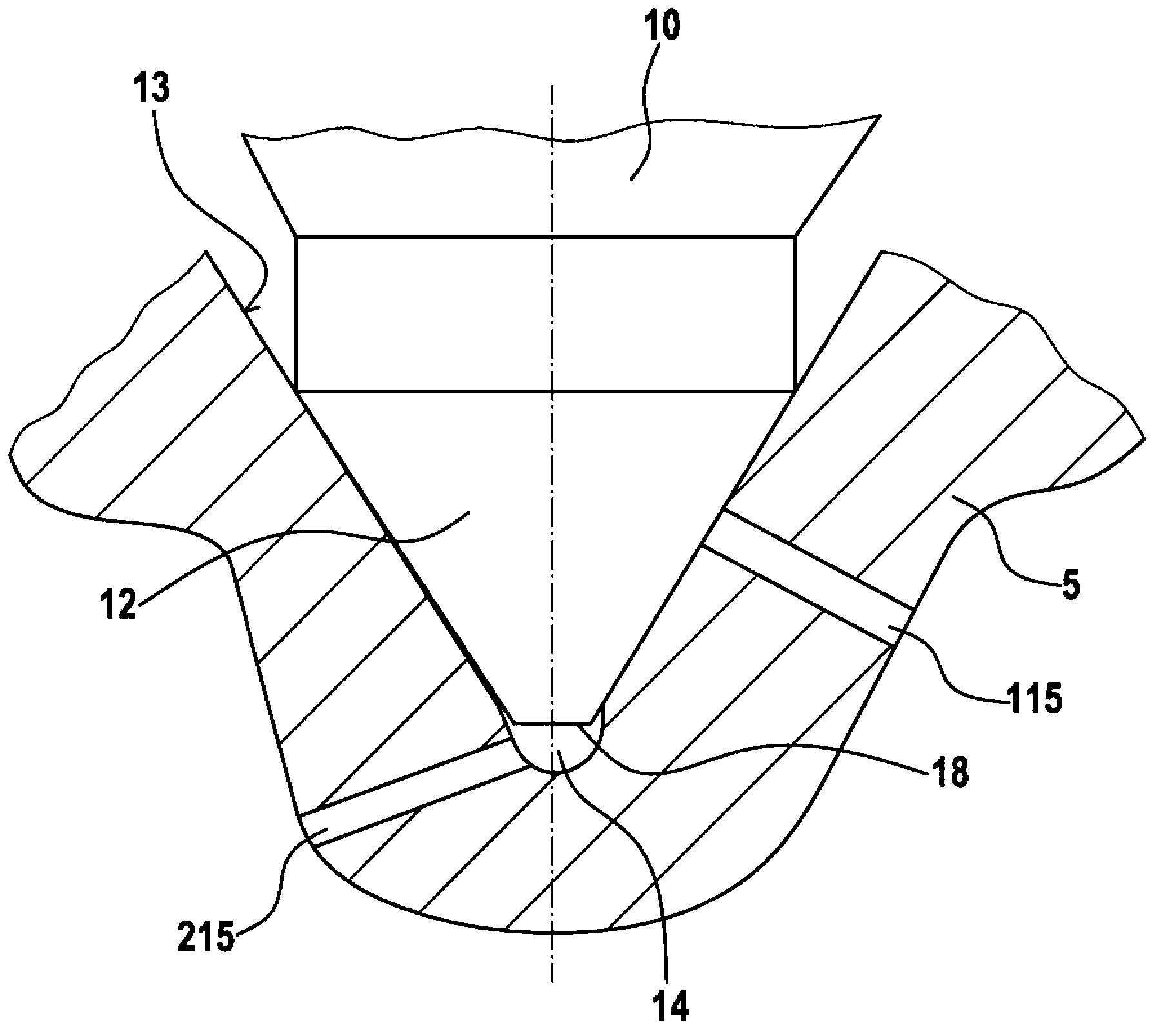

[0026] exist figure 1 shows a fuel injector 1 according to the invention. The fuel injector comprises a holding body 3 and a valve body 5 , wherein the holding body 3 is only partially and schematically shown, while the valve body 5 is shown in longitudinal section. The valve body 5 clamps the holding body 3 by means of a clamping nut 6 and has a pressure chamber 7 which is designed as a stepped bore and is delimited at the end of the valve body 5 on the combustion chamber side by a conical valve seat 13 . At the outermost end, the valve seat 13 merges into a blind hole 14 from which a plurality of injection holes 15 originate. A piston-shaped valve needle 10 is arranged longitudinally displaceable in the pressure chamber 7 and is guided in the central region of the pressure chamber 7 . The fuel flow is ensured in the region of the valve needle guide by a plurality of sharpenings 17 on the valve needle 10 , wherein the sharpenings 17 are formed in the region of the guide of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com