A kind of bopet protective film for heat-resistant fireproof board

A fireproof board and protective film technology, which is applied in the direction of fireproof coatings, coatings, layered products, etc., can solve the problems of poor heat shrinkage, flame retardancy and fireproof performance, and achieve the effect of strengthening uniformity and improving heat resistance and fireproofness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

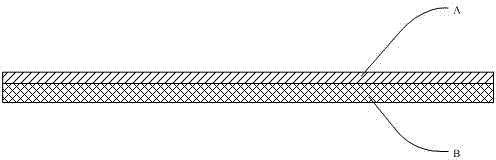

Image

Examples

Embodiment 1

[0027] Silicone coating composition by weight:

[0028] 60 parts by weight of ethanol

[0029] 10 parts by weight of tetraethoxysilane

[0030] Dimethyldiethoxysilane 20 parts by weight

[0031] Silicon dioxide 3 parts by weight

[0032] 8 parts by weight of hydrochloric acid

[0033] 80 parts by weight of water

[0034] Evenly mix 60 parts by weight of ethanol, 10 parts by weight of hydrochloric acid (the concentration of hydrochloric acid solution is 10.54wt%) and 80 parts by weight of water to obtain a mixed solution. Take 10 parts by weight of tetraethoxysilane (Shanghai Zhixin Chemical Co., Ltd., purity: 99%), 20 parts by weight of dimethyldiethoxysilane (Shanghai Ethyl Chemical Co., Ltd., purity >97%), and 3 parts by weight of silicon dioxide (Wacker, Germany, model: V15), added to the mixed solution, Stir continuously to obtain a coating solution.

[0035] Clean the corona-treated (corona value 48 dyne) BOPET film surface with a thickness of 135 μm with alcohol to...

Embodiment 2

[0037] Silicone coating composition by weight:

[0038] 50 parts by weight of ethanol

[0039] 15 parts by weight of methyltriethoxysilane

[0040] 25 parts by weight of methylphenyldiethoxysilane

[0041] Silica 2 parts by weight

[0042] 6 parts by weight of hydrochloric acid

[0043] 70 parts by weight of water

[0044] 50 parts by weight of ethanol, 6 parts by weight of hydrochloric acid (the concentration of hydrochloric acid solution is 10.54wt%) and 70 parts by weight of water are uniformly mixed to obtain a mixed solution, and 15 parts by weight of methyltriethoxysilane (Nanjing Qianqian Chemical Co., Ltd., content ≥99%), 25 parts by weight of methylphenyldiethoxysilane (Hangzhou Kawei Chemical Technology Co., Ltd., content ≥98%), 2 parts by weight of silica (Wacker, Germany, model: V15) were added The solutions were mixed and continuously stirred evenly to obtain a coating solution.

[0045] Clean the corona-treated (corona value 48 dyne) BOPET film surface with...

Embodiment 3

[0047] Silicone coating composition by weight:

[0048] 60 parts by weight of ethanol

[0049] Dimethyldiethoxysilane 35 parts by weight

[0050] Titanium dioxide 3 parts by weight

[0051] 10 parts by weight of hydrochloric acid

[0052] 80 parts by weight of water

[0053] 60 parts by weight of ethanol, 10 parts by weight of hydrochloric acid (the concentration of hydrochloric acid solution is 10.54wt%) and 80 parts by weight of water are uniformly mixed to obtain a mixed solution, and 35 parts by weight of dimethyldiethoxysilane (Hebei Taifeng Chemical Co., Ltd. company, content: 97%), 3 parts by weight of titanium dioxide (Baisen Yanling Nano Technology Co., Ltd., model: N6028B), added to the mixed solution, and continuously stirred evenly to obtain a coating solution.

[0054] Clean the corona-treated (corona value 52 dynes) BOPET film surface with a thickness of 135 μm with alcohol to remove oil and impurities, and dry it with hot air. , coated with a thickness of 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com