Building internal wall thermal insulation and fire resistance structure

A fireproof structure and building technology, applied in the field of building walls, can solve the problems of unsuitable construction of complex structures with special shapes, walls penetrating cold and mildew, and complicated construction processes, so as to solve the problems of cold and mildew, reduce energy consumption, Good overall sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

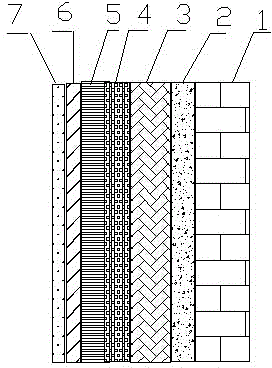

[0019] A building interior wall thermal insulation and fire prevention structure, comprising a wall, the wall 1 is provided with an adhesive layer 2, the adhesive layer 2 is provided with an insulating layer 3, and the insulating layer 3 is provided with a reinforcing layer 4, the The reinforcing layer 4 is provided with a thermal insulation layer 5 , the thermal insulation layer 5 is provided with a decorative layer 6 , and the decorative layer 6 is provided with a paint layer 7 . The material of the adhesive layer is brine glue. The brine glue is formed by stirring brine and magnesium oxide powder. The material of the insulation layer is magnesium oxide board. The material of the reinforcement layer is glass fiber mesh cloth and brine glue. The material of the thermal insulation layer is extruded plastic board. The decorative layer mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com