Device for realizing vertical lifting by using film-grade laminator flow

A membrane-level, airflow-direction technology, applied in jet flaps and other directions, can solve problems such as high fuel consumption, poor rotor aerodynamic performance, and low efficiency in the vertical take-off process, achieving the effect of saving fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

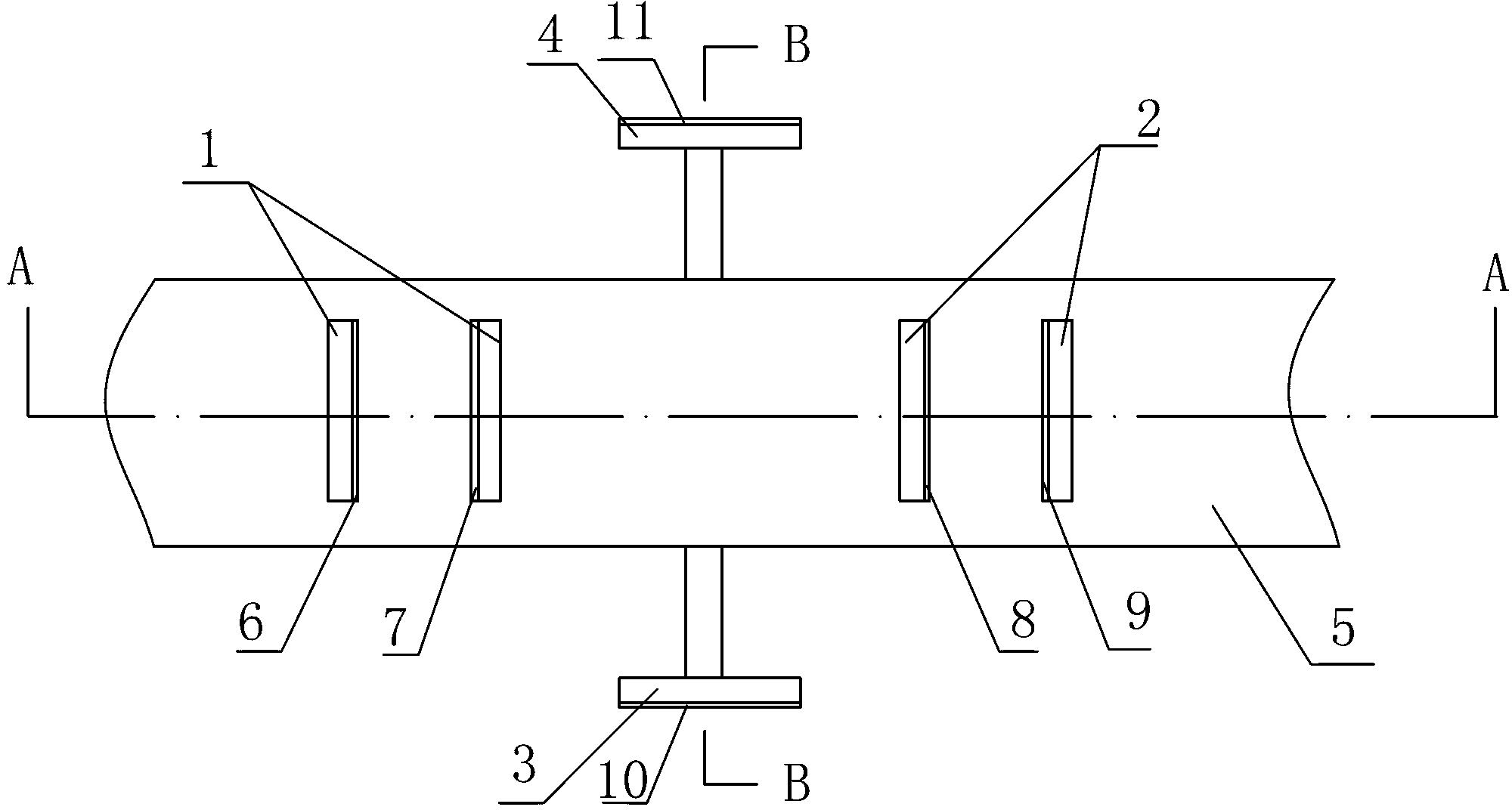

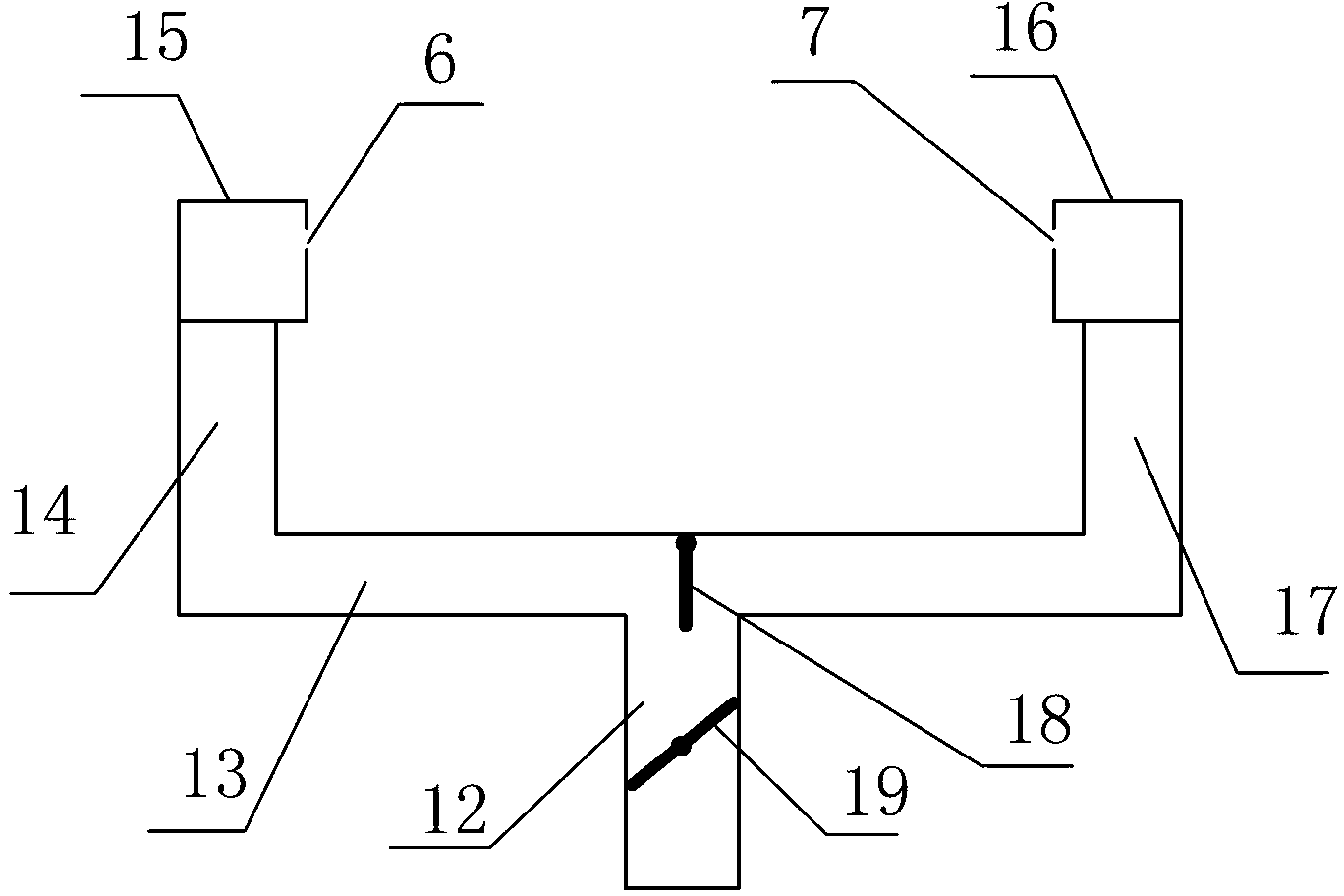

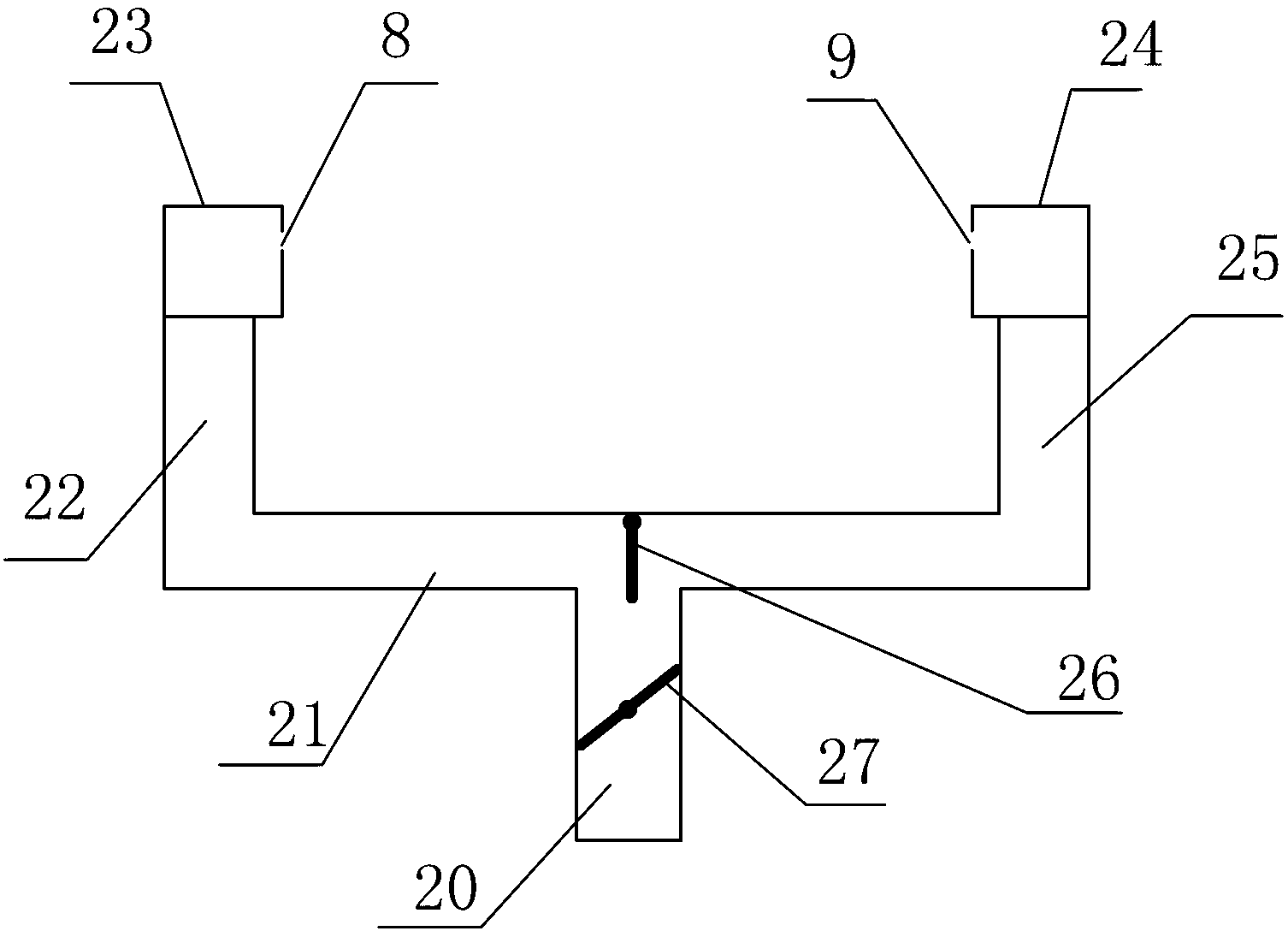

[0028] The present invention utilizes the schematic diagram of the device of film-level laminar flow to realize direct lift as Figure 1-Figure 5 As shown, it includes a gas source, a gas transmission main pipe, and a slit A unit 1, a slit B unit 2, a slit C unit 3 and a slit D unit 4. One end of the gas transmission main pipe is sealed, and the other end is connected to the The air source connection, the air source can be a turbojet engine, or a turbofan engine, or a combination of other types of engines and axial fans or centrifugal fans. The slit A unit 1 is composed of two first slits 6 and second slits 7 with opposite airflow directions and an airflow direction control valve A18 controlling the airflow direction of the slit A unit. The first slit 6 Between the second narrow slit 7 is a zone A of laminar flow straight up. The sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com