Prestress tensioning device and use method of fiber cloth

A technology of tensioning device and fiber cloth, which is applied in building maintenance, processing of building materials, construction, etc., can solve the problems that the components cannot meet the normal use requirements, and the elastic modulus of high-strength fiber cloth is not higher than that of steel, so as to achieve easy construction and site The effect of low requirements, simple and smart structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

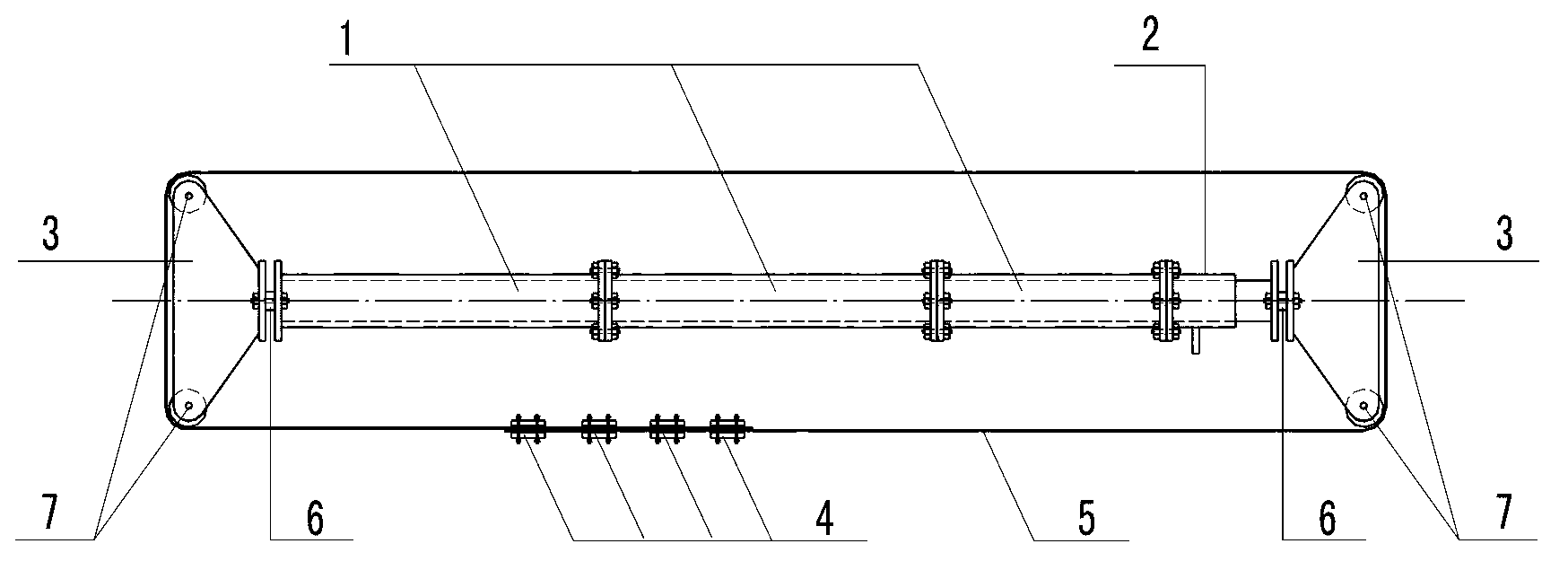

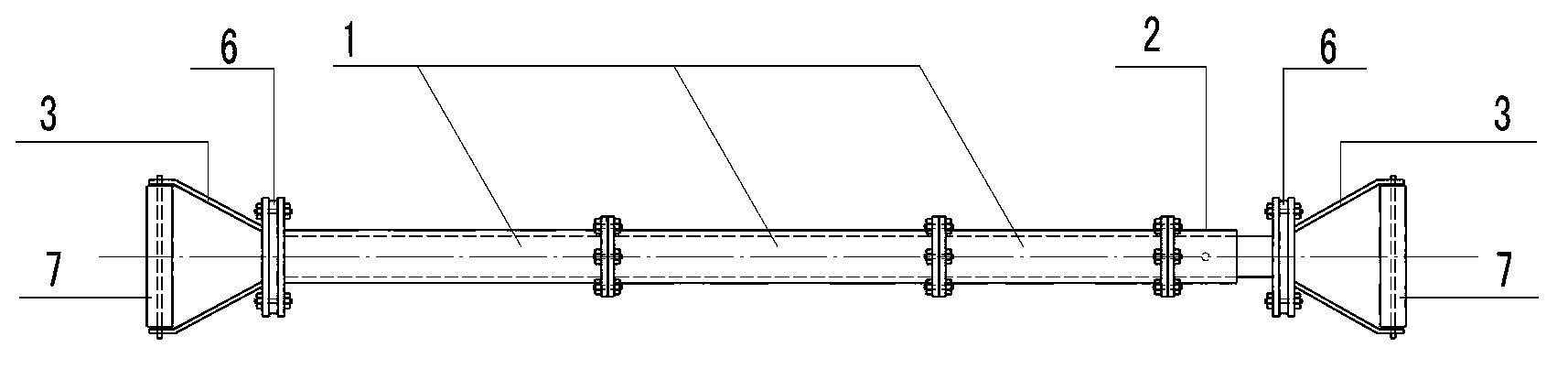

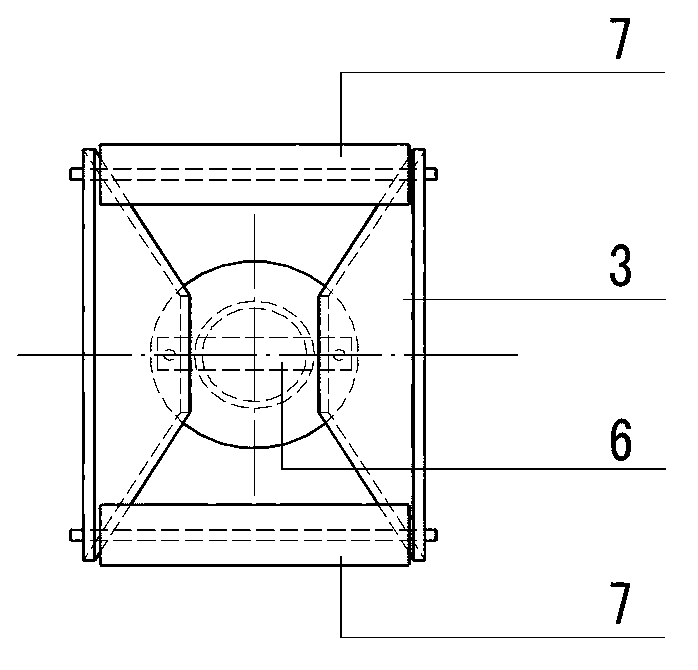

[0034] All parts of this device are made of high-strength steel such as Q345. The section size of the strut 1 is determined according to the common beam-slab span, the length of the roller 7 of the steel member 3 is determined according to the common beam width, and the steel member is determined according to the common loading value and the construction operation space. 3 size specifications. The strut 1 is made of multiple steel pipes fixedly connected by flanges, and several sets of different specifications and lengths should be produced to suit transportation and on-site assembly. The steel backing plate 6 is used to reduce the influence of the bending moment at the end when the hydraulic jack 2 is unloaded.

[0035] Before construction, according to figure 1 According to the connection method shown in , according to the length of the reinforced member, the stretching amount of the fiber cloth, the space size and other data, the strut 1 is assembled on site; then the hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com