Quick inspection jig for product inner hole 90-degree angle

A fixture and inner hole technology, applied in the field of machinery, can solve problems such as low efficiency and prone to errors, and achieve the effect of reducing labor and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings.

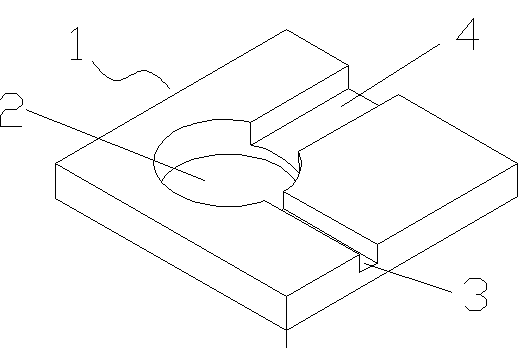

[0010] Such as figure 1 As shown, a product inner hole 90-degree quick inspection jig includes a jig body 1, the jig body 1 is provided with an installation groove 2 for placing the product to be tested, and the jig body 1 is also provided with There are two first through-slots 3 and second through-slots 4 that communicate with the installation groove 2 and are perpendicular to each other. After putting the product to be tested into the installation groove 2, insert two round rods with the same diameter as the inner hole from the first through groove 3 and the second through groove 4 into the inner hole of the product to be tested, if two If the round rods can be inserted at the same time, it means that the product is qualified.

[0011] The width of the first through groove 3 is consistent with the diameter of the inner hole, and the width of the second through groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com