Flushing control method and device for station of bottle washing machine

A control method and technology for a bottle washing machine, which are applied in the directions of electrical program control, chemical instruments and methods, cleaning methods and utensils, etc. The effect of water channeling at the station, reducing the cost of the device and reducing the energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention are described in detail below:

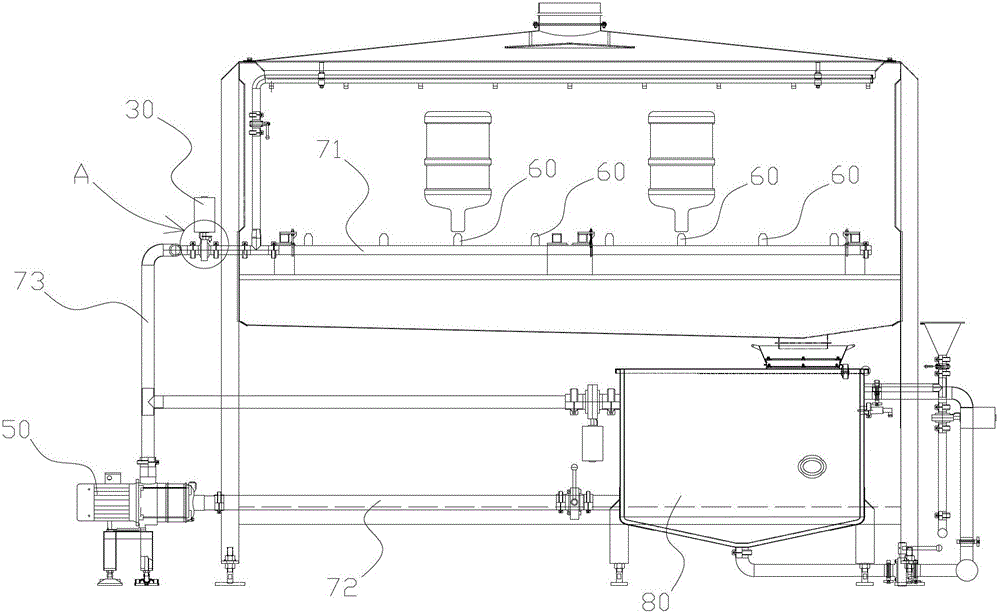

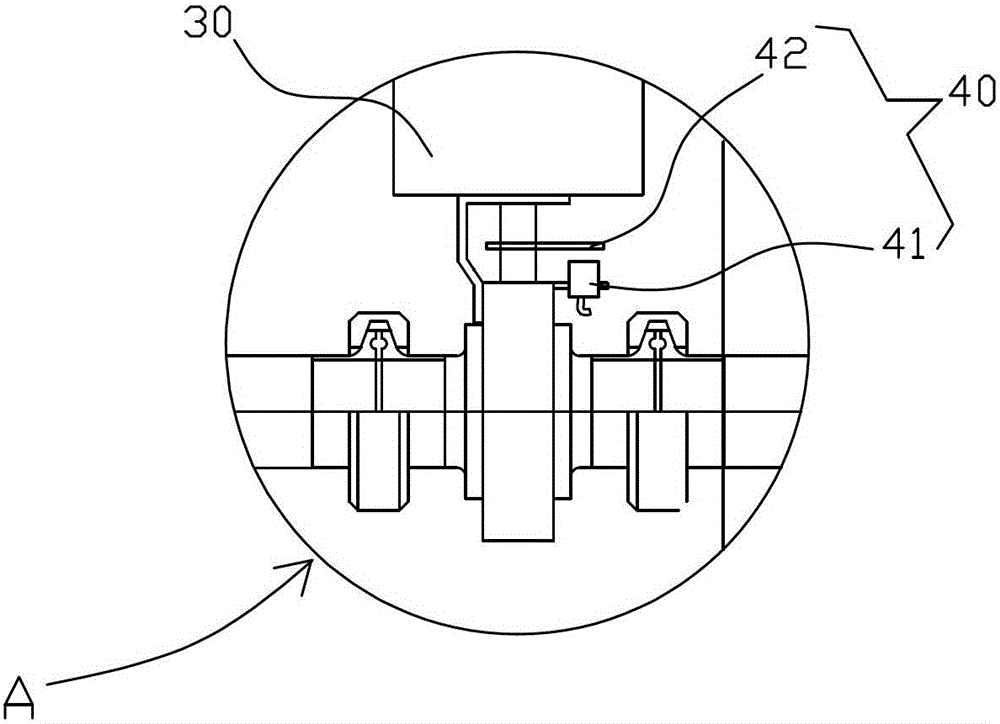

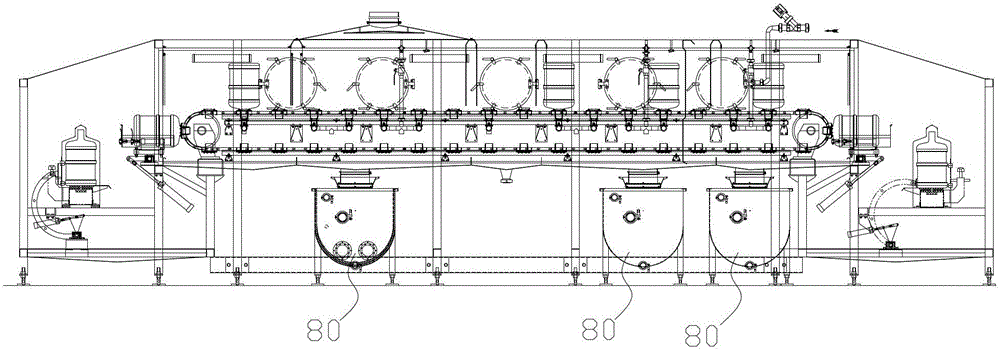

[0027] Such as Figure 1 to Figure 5 As shown, a station flushing control device for a bottle washing machine includes a central controller, a detection device, a station valve 30, a water pump 50, a nozzle 60 and a flushing pipeline, and the detection device, station valve 30 and water pump 50 They are respectively electrically connected to the central controller, and the water pump 50, the station valve 30 and the spray head 60 are sequentially installed on the flushing pipeline along the flow direction of the water flow in the flushing pipeline.

[0028] Wherein, the detection device is a bottle loading detector installed on the bottle loading mechanism 10 of the bottle washing machine, and the signal output end of the bottle loading detector is connected with the signal input end of the central controller. The bottle-loading detector includes a photoelectric detection switch 21 and a reflector 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com