Center-adjusting device for pressing and assembling bearing

A technology of bearings and self-aligning bearings, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as increased rotor noise, increased production costs, and reduced work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

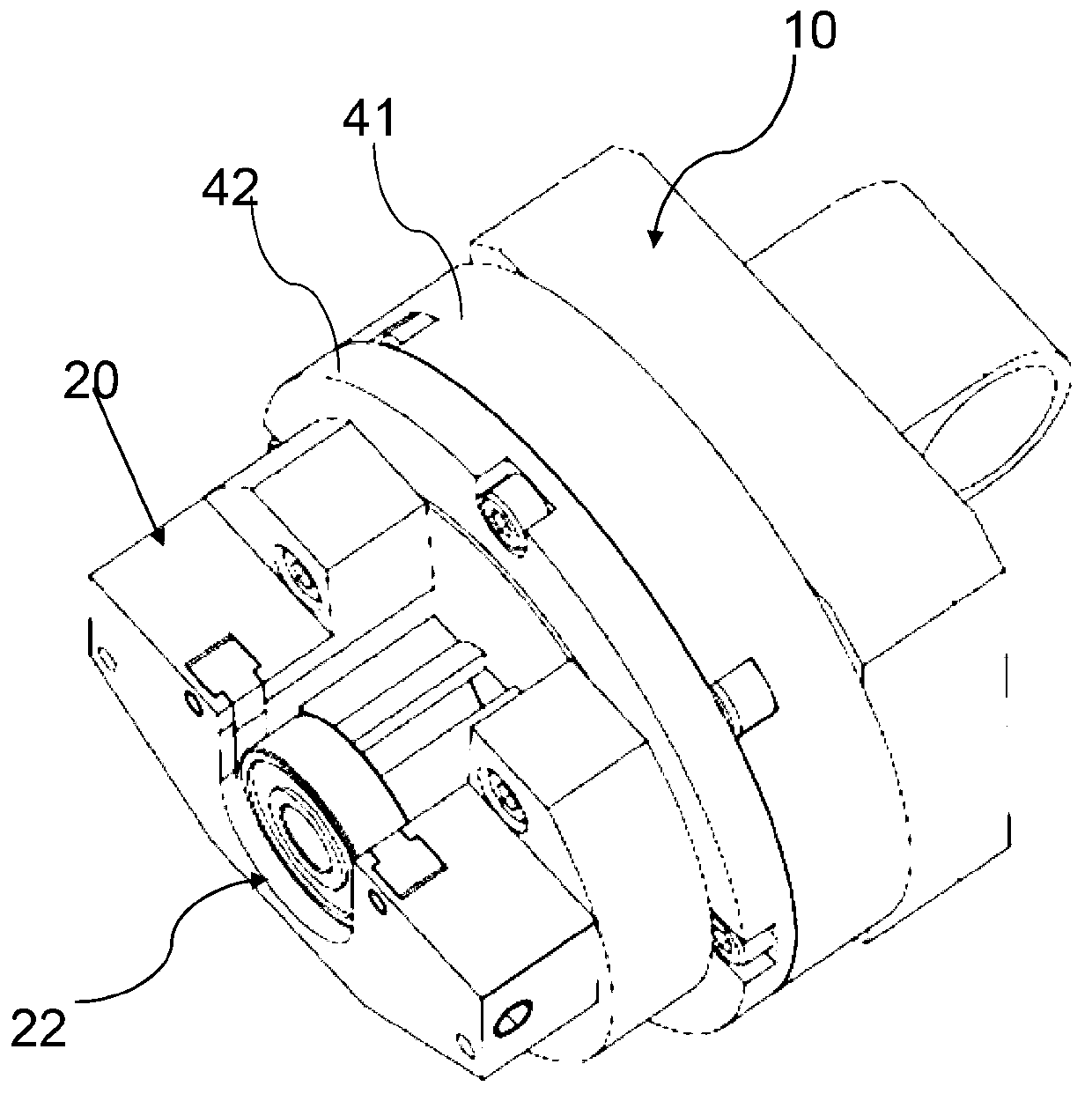

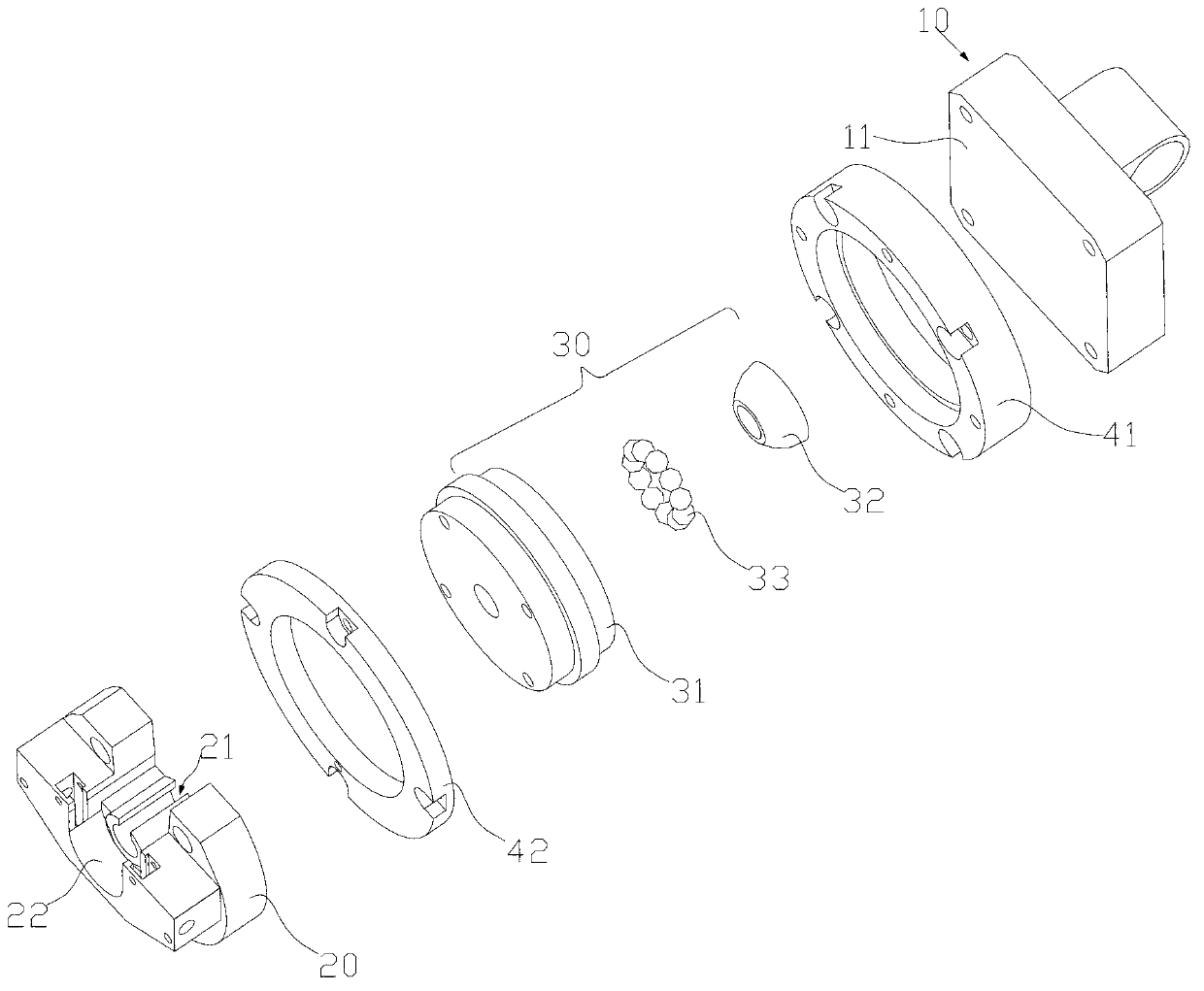

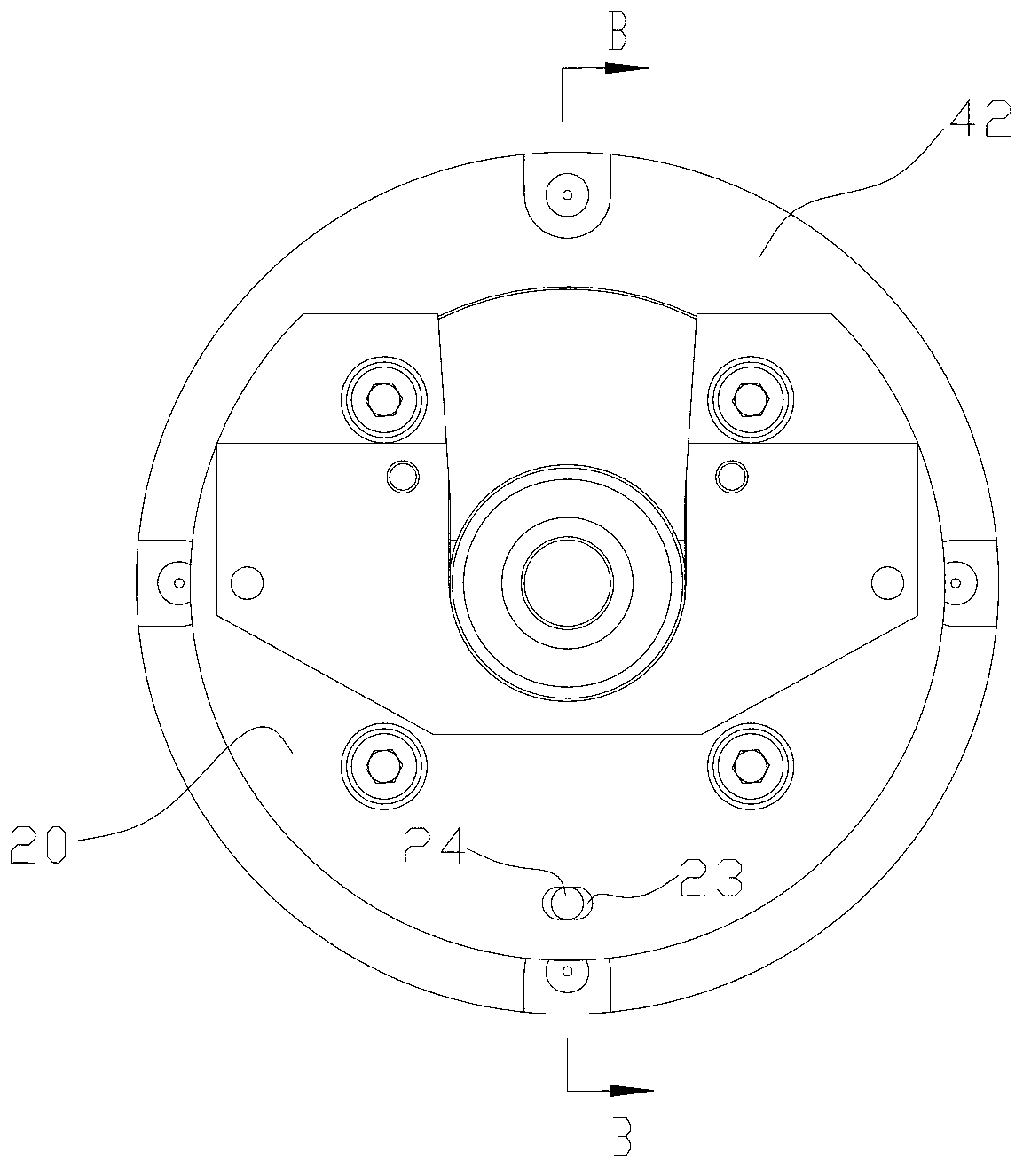

[0013] Such as Figure 1-3 , a centering device for press-fitting bearings, including a bracket 10 and a support 20 for placing the bearing to be assembled. The support 20 is provided with a hole 21 for the shaft to be assembled to pass through. Between the support 20 and the bracket 10 A self-aligning bearing assembly 30 is provided, and the inner and outer rings of the self-aligning bearing assembly 30 are respectively connected to the bracket 10 at the support 20 . The inner ring and the outer ring of the self-aligning bearing assembly 30 can float with each other, and the axes of the two may not coincide, that is to say, the axis of the outer ring can be deflected relative to the axis of the inner ring, so the support 20 connecting the outer ring It can be deflected and floated relative to the bracket 10, and there is a movable fit between the two. When press-fitting the bearing, the rotor shaft passes through the inner hole of the bearing to be assembled and overhangs to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com