Automatic-opening-closing conveying mechanism with three rollers rotating automatically for cylinders

A conveying mechanism, self-opening and closing technology, applied in the direction of roller table, transportation and packaging, etc., can solve the problems of wear of the conveying center, difficulty in ensuring center precision control, displacement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, technical features, invention objectives and technical effects realized by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

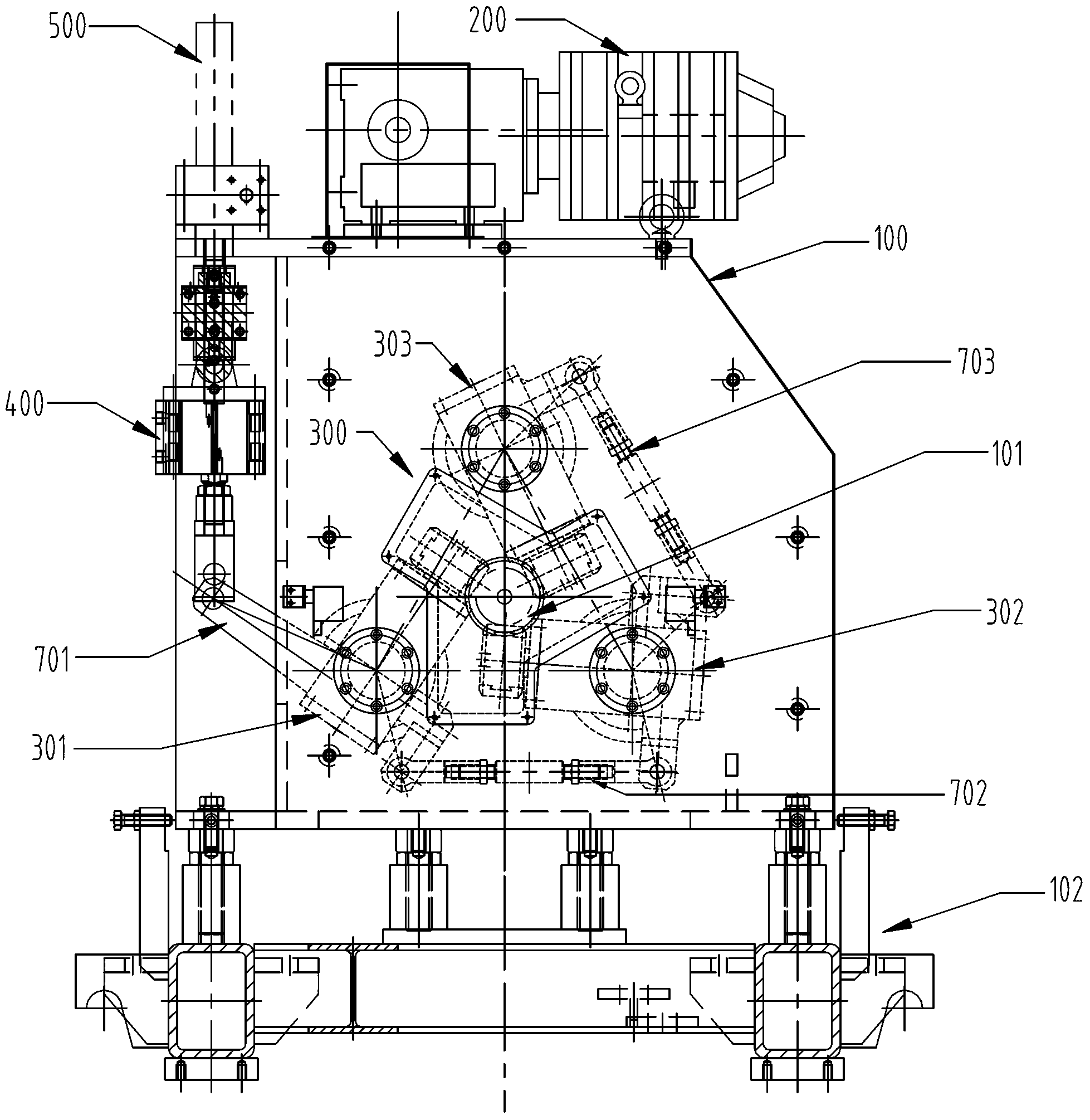

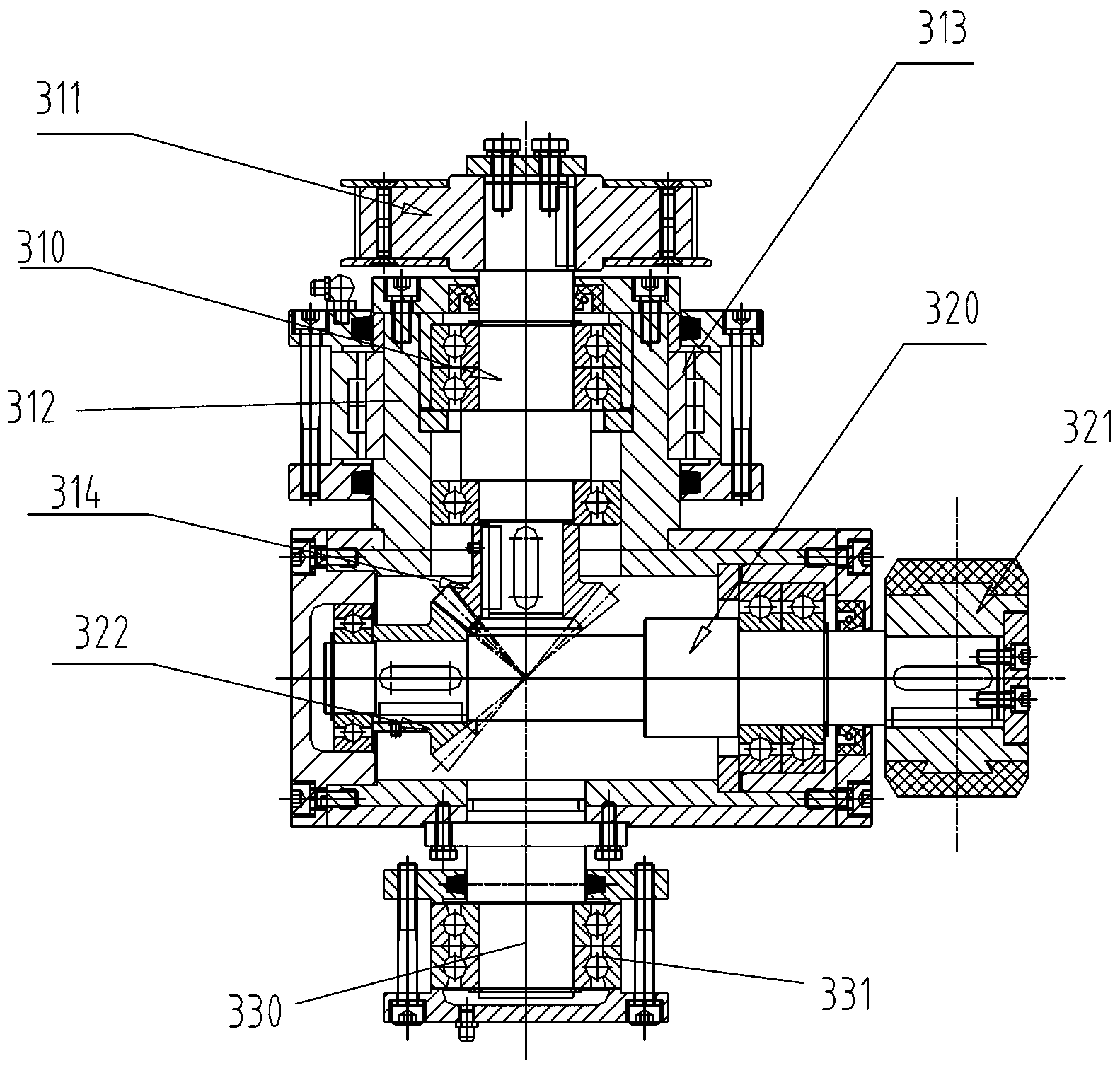

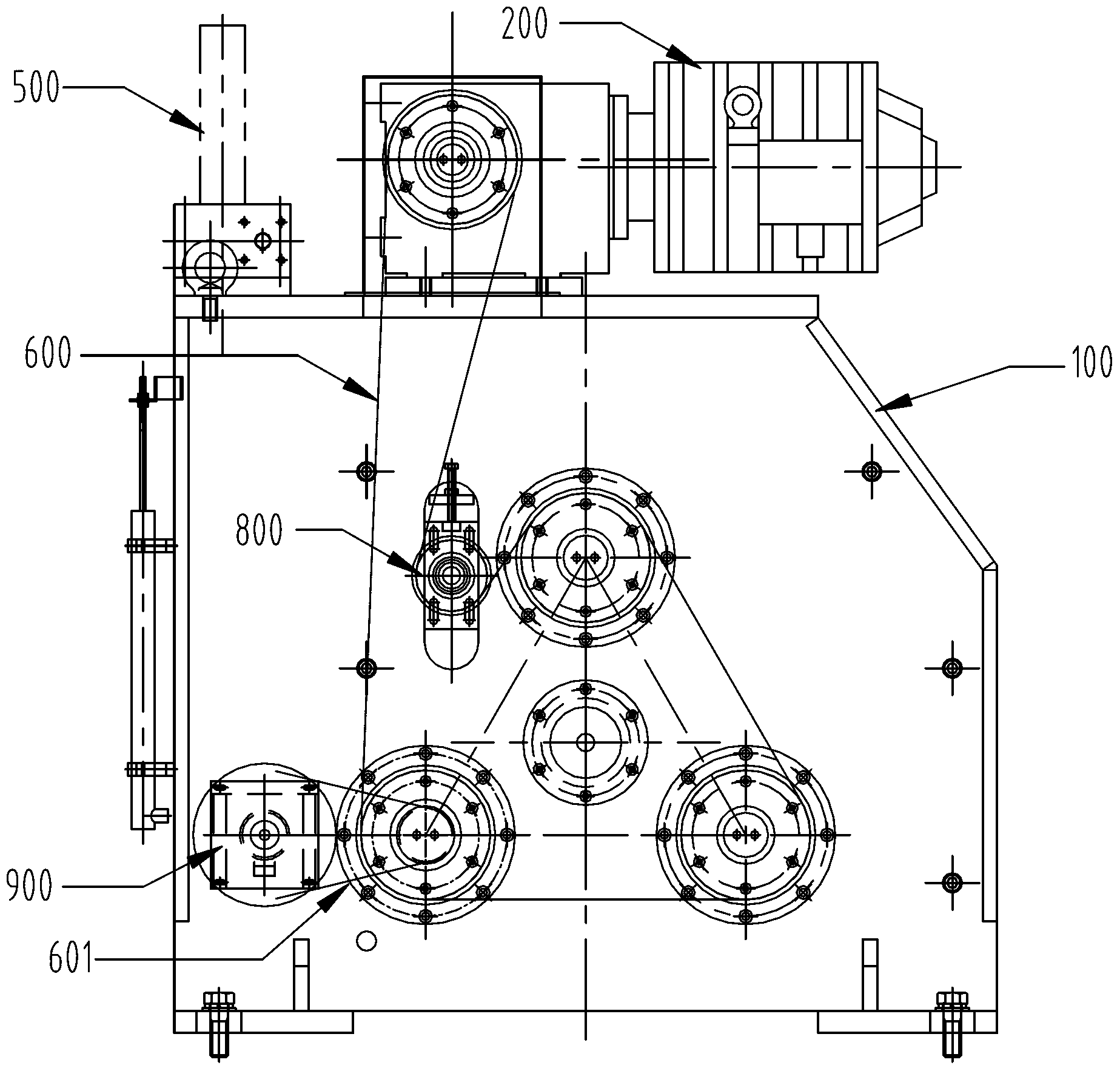

[0023] Such as figure 1 Shown is a three-roller active rotating self-opening cylinder conveying mechanism of the present invention, which includes a body 100 inside which is provided with a conveying channel 101 that runs through the entire body, and the body 100 is installed on a base 102 . It also includes a rotary driving motor 200 arranged on the top of the body 100 , a clamping rotating roller 300 , a pneumatic or hydraulic small-stroke opening and closing actuator 400 installed on the side plate of the body 100 , and a large-stroke driving screw 500 . The rotation driving motor 200 drives the clamping rotating roller 300 through the first synchronous toothed belt 600 to rotate the conveying pipe or rod. One end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com