Straight jacking type freight lifting platform

A lifting platform, straight top technology, applied in the direction of lifting frame, lifting device, etc., can solve the problem of low safety and reliability of lifting platform, achieve the effect of increasing safety performance and reliability, and slowing down the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

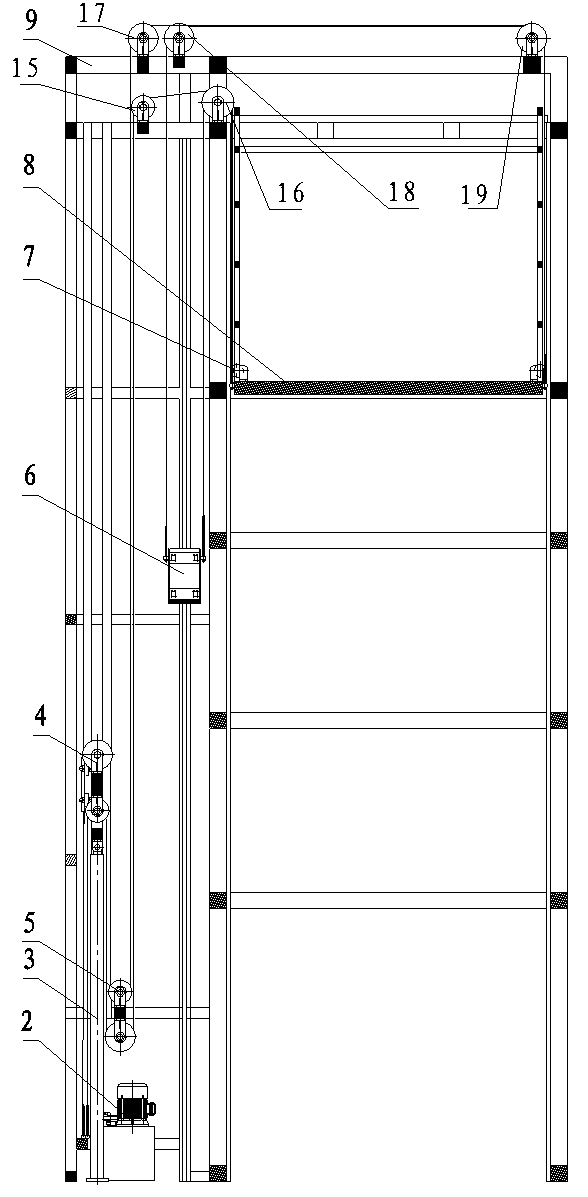

[0014] Below in conjunction with accompanying drawing example, the present invention is described in further detail:

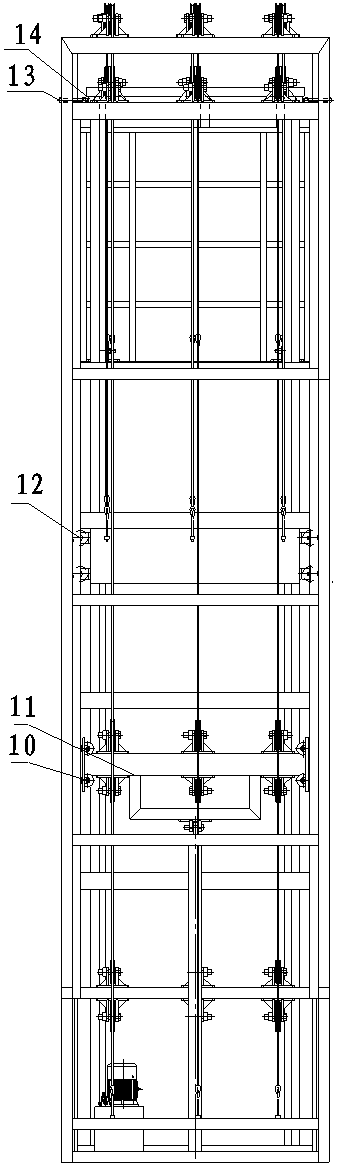

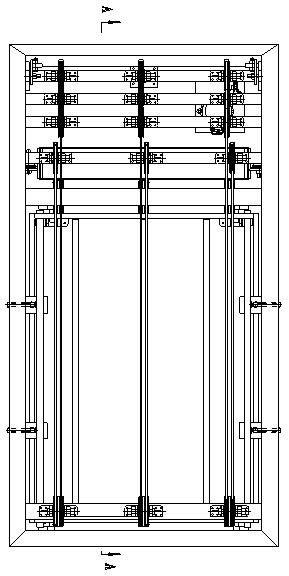

[0015] Such as figure 1 , figure 2 and image 3 The present embodiment shown includes a skeleton main body 9, a hydraulic cylinder 3 and a hydraulic pump 2 installed at the lower part of the skeleton main body, and a cargo lifting platform 8 driven by three sets of wire rope pulley windings driven by the hydraulic cylinder. The upper part is provided with a push rod 14 driven by the anti-falling cylinder 13, which stretches out laterally during operation; , the third fixed pulley 17, the fourth fixed pulley 18 and the fifth fixed pulley 19; the anti-fall counterweight 6 is installed on the skeleton main body 9 through the counterweight guide wheel 12, and the anti-fall counterweight is pulled by the wire rope pulley winding, The wire ropes 1 on both sides of the anti-fall counterweight are connected to the two sides of the cargo lifting platform 8 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com