Washing machine drain valve retractor

A technology of drain valve and tractor, which is applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of high manufacturing cost and failure rate, easy corrosion damage, complex structure, etc., and achieves low cost and reliable performance. , the effect of less failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

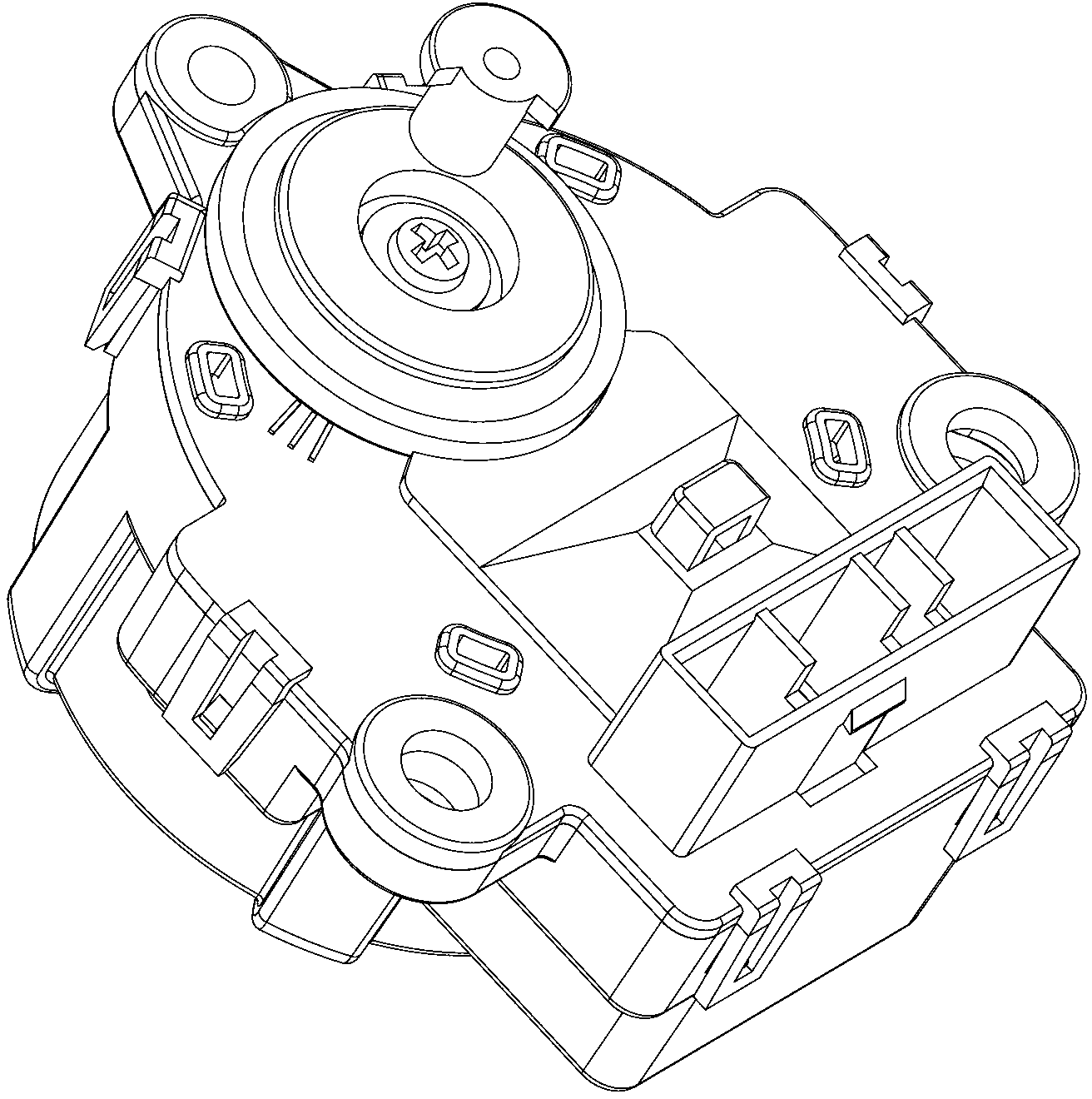

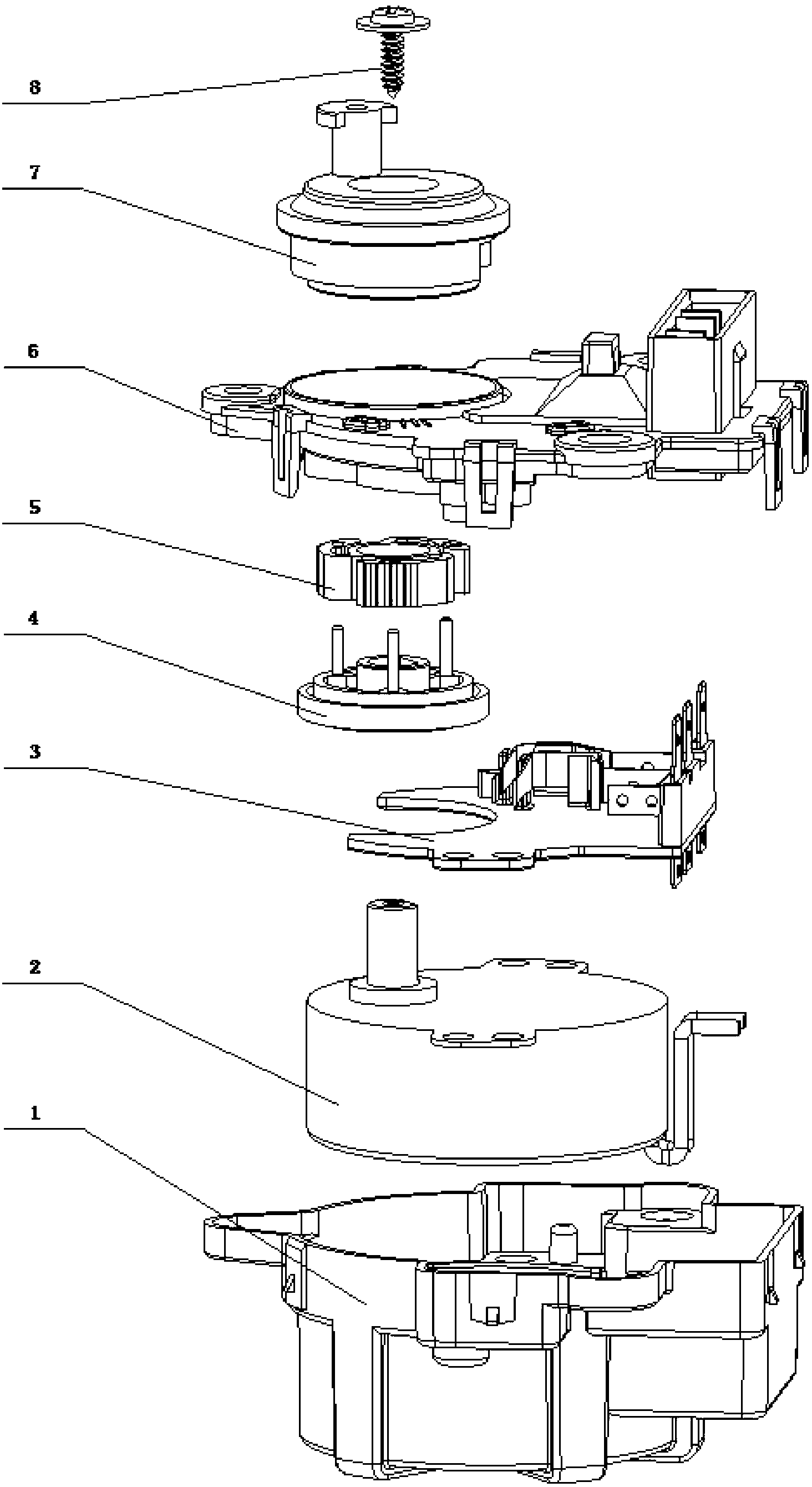

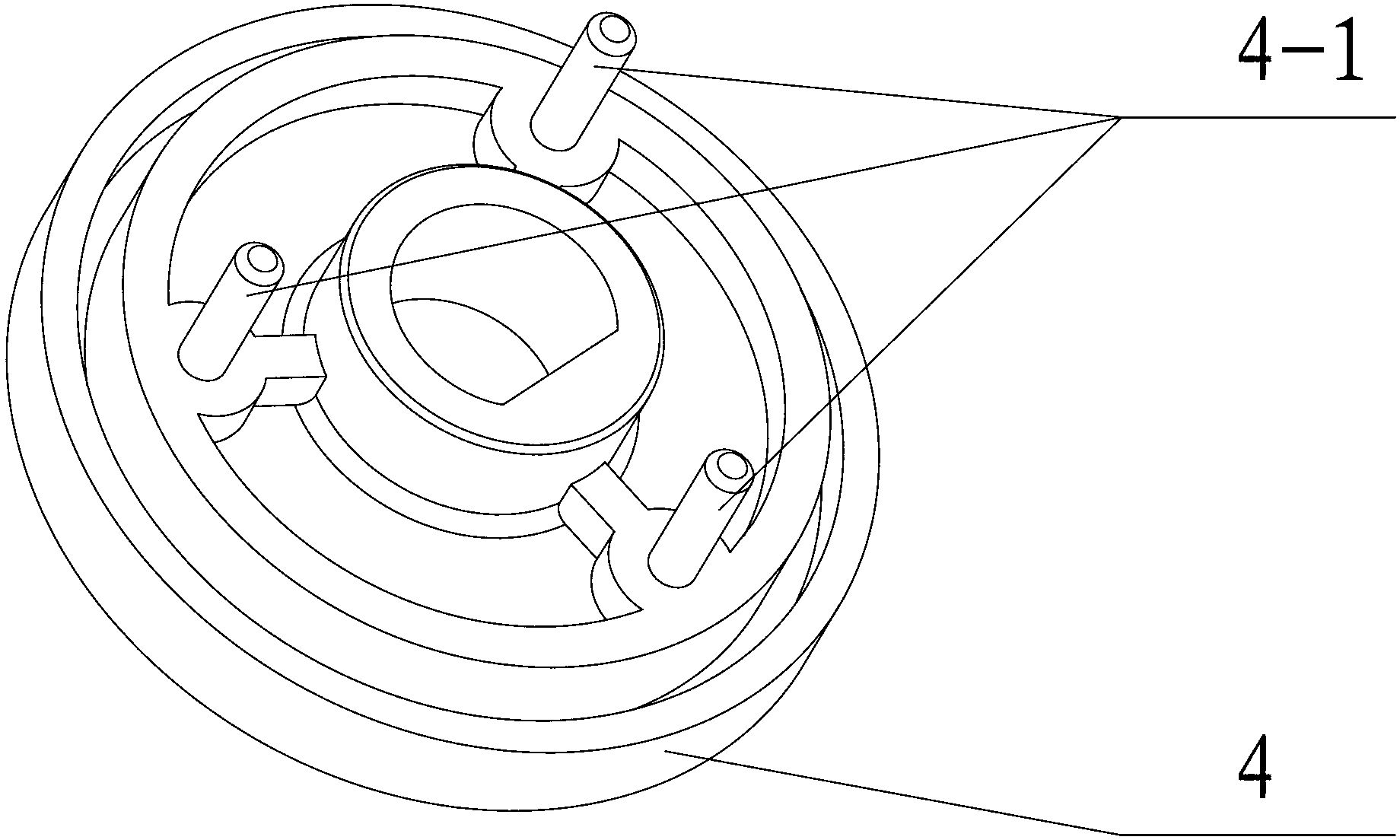

[0013] Such as figure 1 , 2 As shown, a washing machine drain valve puller includes a synchronous motor 2 installed in the motor base 1, a terminal bracket 3 and an upper cover 6 installed on the end face of the motor base, and a motor rotor passing through the wheel installed in the synchronous motor. The output gear of the gear transmission is connected with rotating parts on the output gear shaft. The rotating part is composed of a drive wheel, a transmission wheel and an output wheel; the circumference of the transmission wheel 5 is provided with three tooth pieces 5-3 with a set of pawls 5-1 in the axial direction respectively (see image 3 ), one end of the tooth piece is equidistantly injection-molded on the circumferential surface of the transmission wheel, and the other end extends in the air along one side of the circumferential surface of the transmission wheel. The ratchet on the outer edge of the toothed piece cooperates with the ratchet 7-1 arranged on the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com