Closestool

A technology for toilets and bedpans, applied in flush toilets, water supply devices, buildings, etc., can solve the problems of increasing the difficulty of product production, and achieve the effects of stable and controllable punching positions and angles, fewer punching numbers, and simple production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

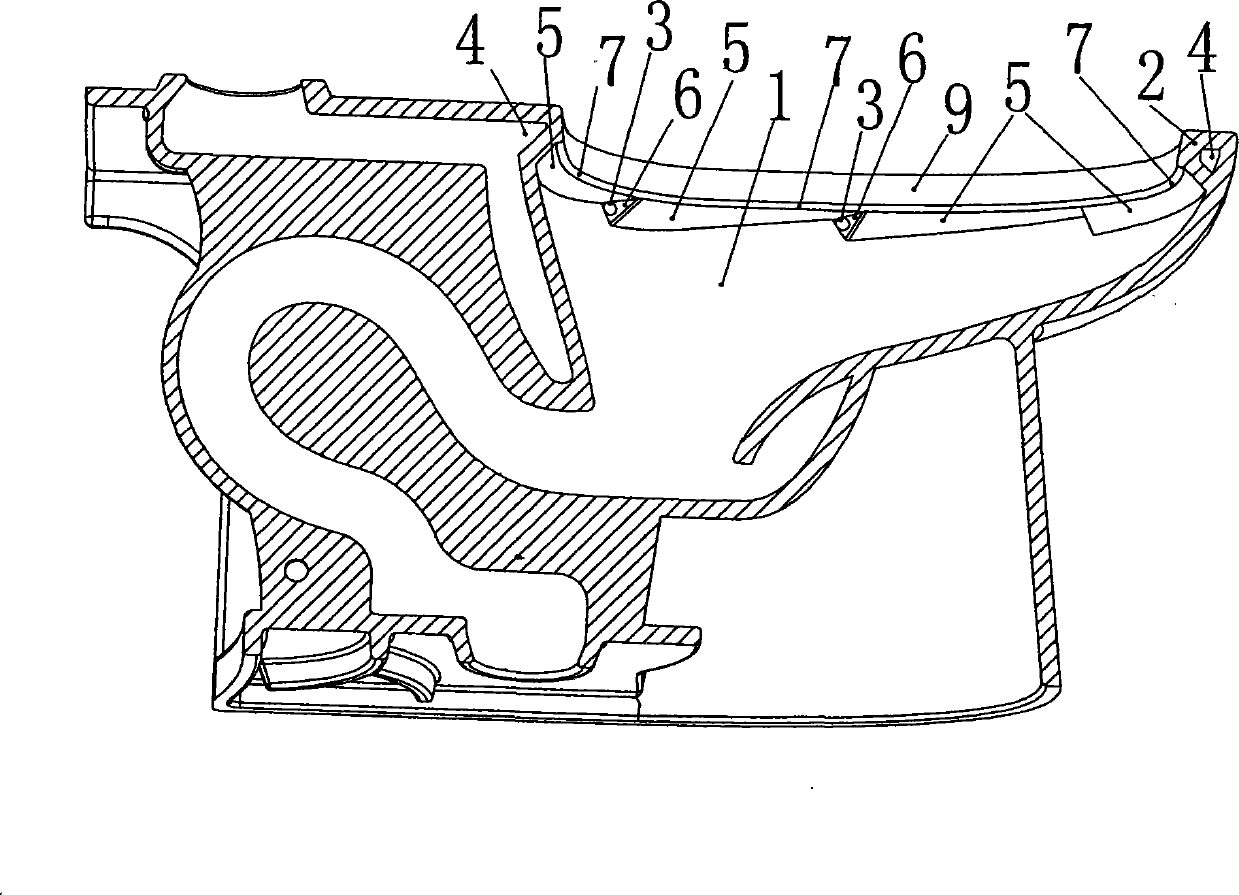

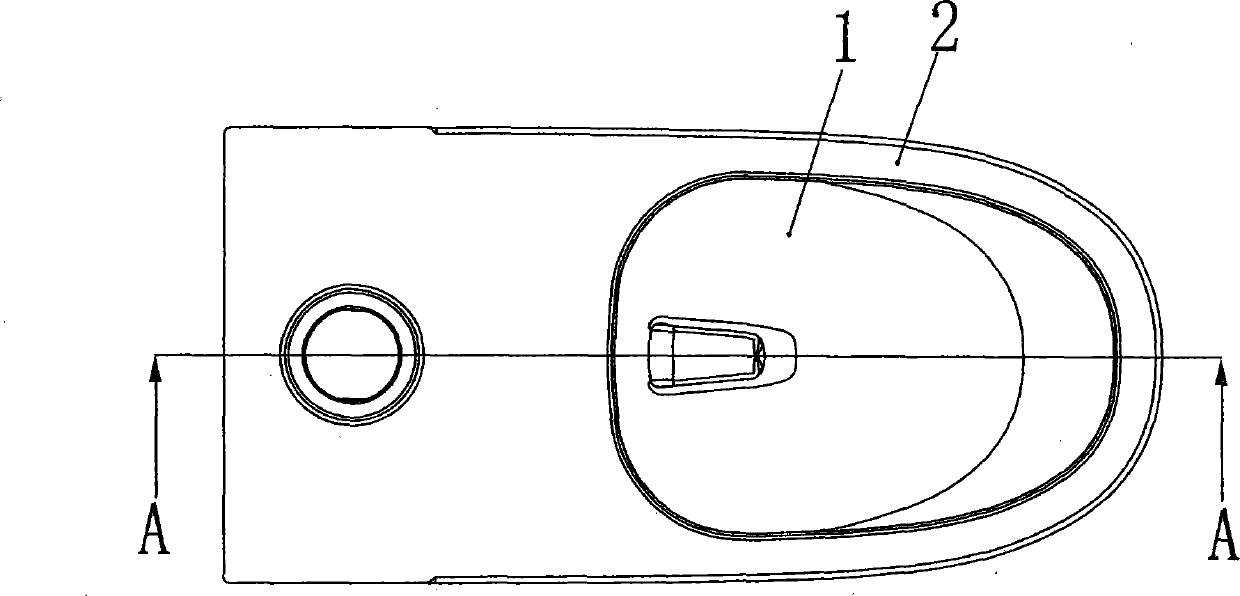

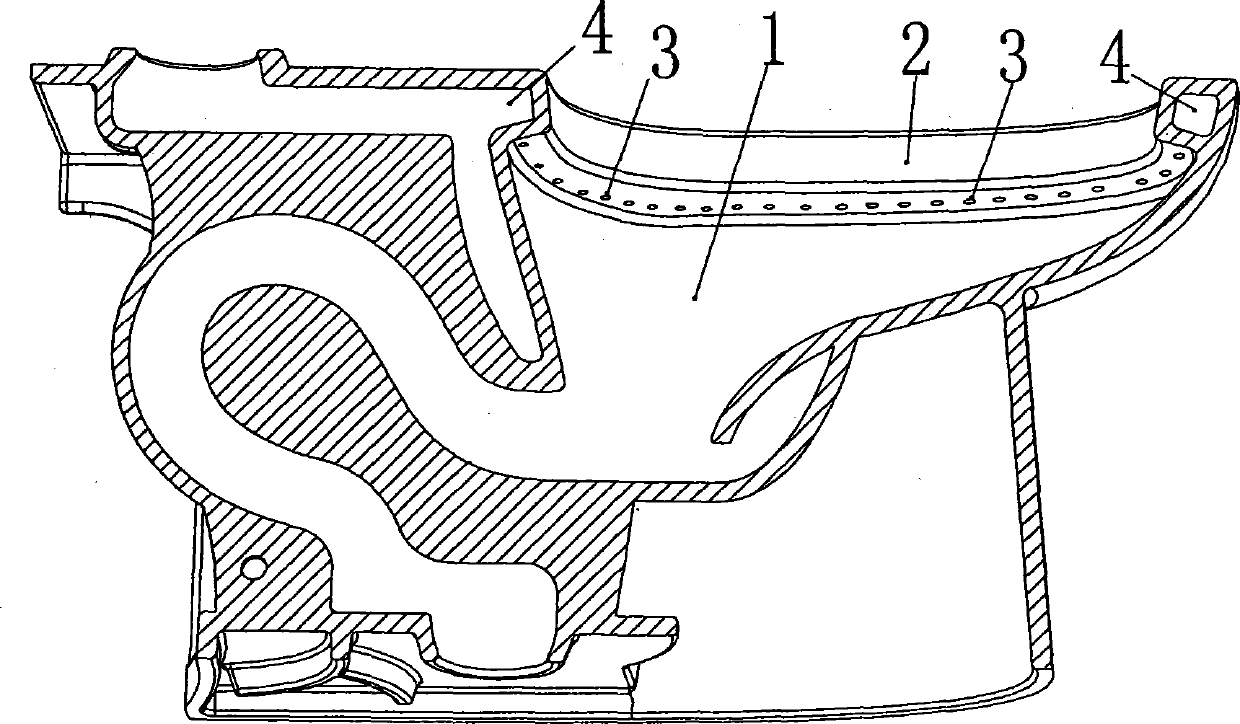

[0031] Comparative reference Figure 5 and image 3 , Figure 6 and Figure 4 The difference between the second embodiment and the first embodiment is that in the second embodiment, there is a water equalizing table 8 surrounding the bedpan 1 on the inner upper part of the bedpan 1, and the water flowing out from the cleaning hole 3 flows into the The water leveling platform 8 then flows to the bottom of the bedpan 1, so that all the inner walls of the bedpan 1 can be cleaned more evenly and comprehensively, and all the other structures are exactly the same as those in the specific embodiment one, and will not be repeated here.

[0032] The present invention emphatically introduces the upper part of the bedpan and the structure of the seat ring, mainly aimed at cleaning the inner wall of the bedpan; regarding the discharge of the dirt in the bedpan, as part of the water discharged from the water tank flows to the spray hole at the bottom of the bedpan through the spray pipe,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com