Closestool

A toilet, bedpan technology, applied in flushing toilets, water supply devices, buildings, etc., can solve problems such as increasing the difficulty of product production, and achieve the effects of stable and controllable punching position and angle, simple production process, and fewer punching holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

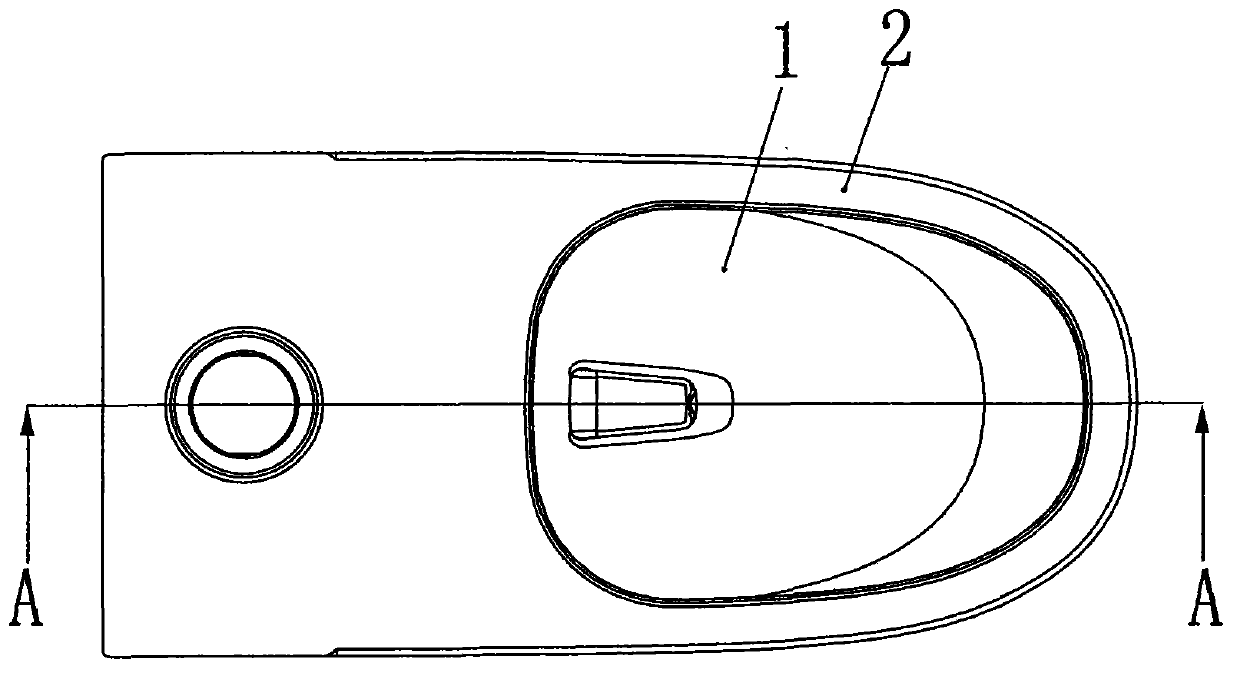

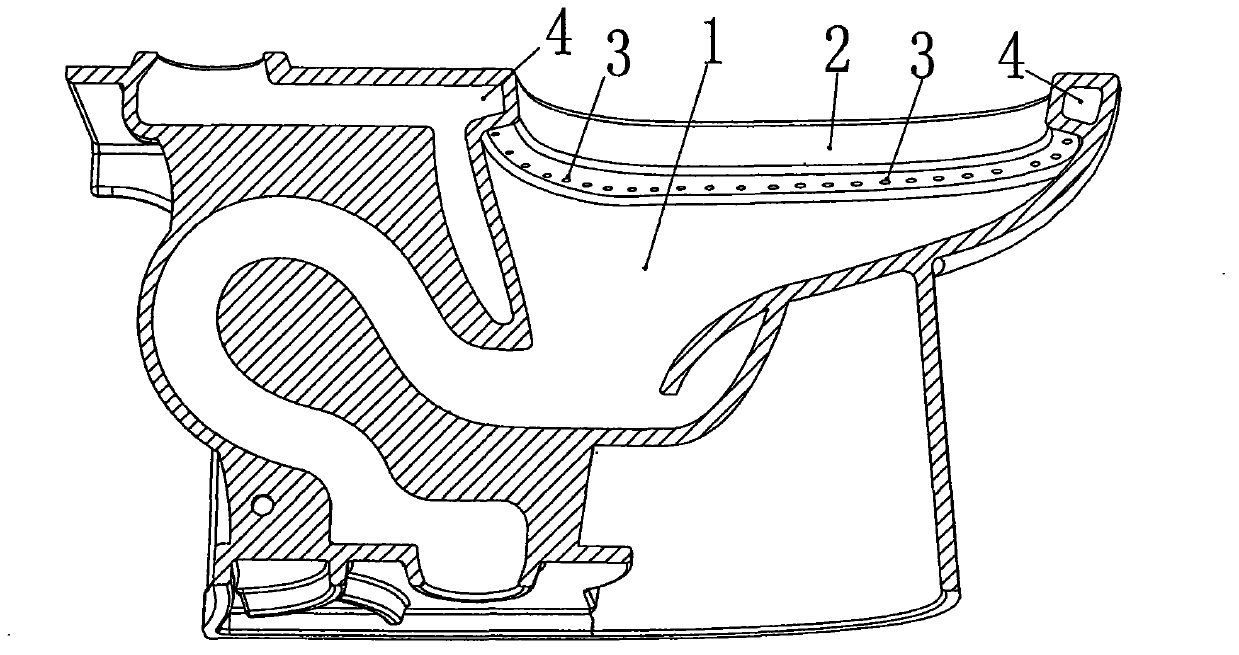

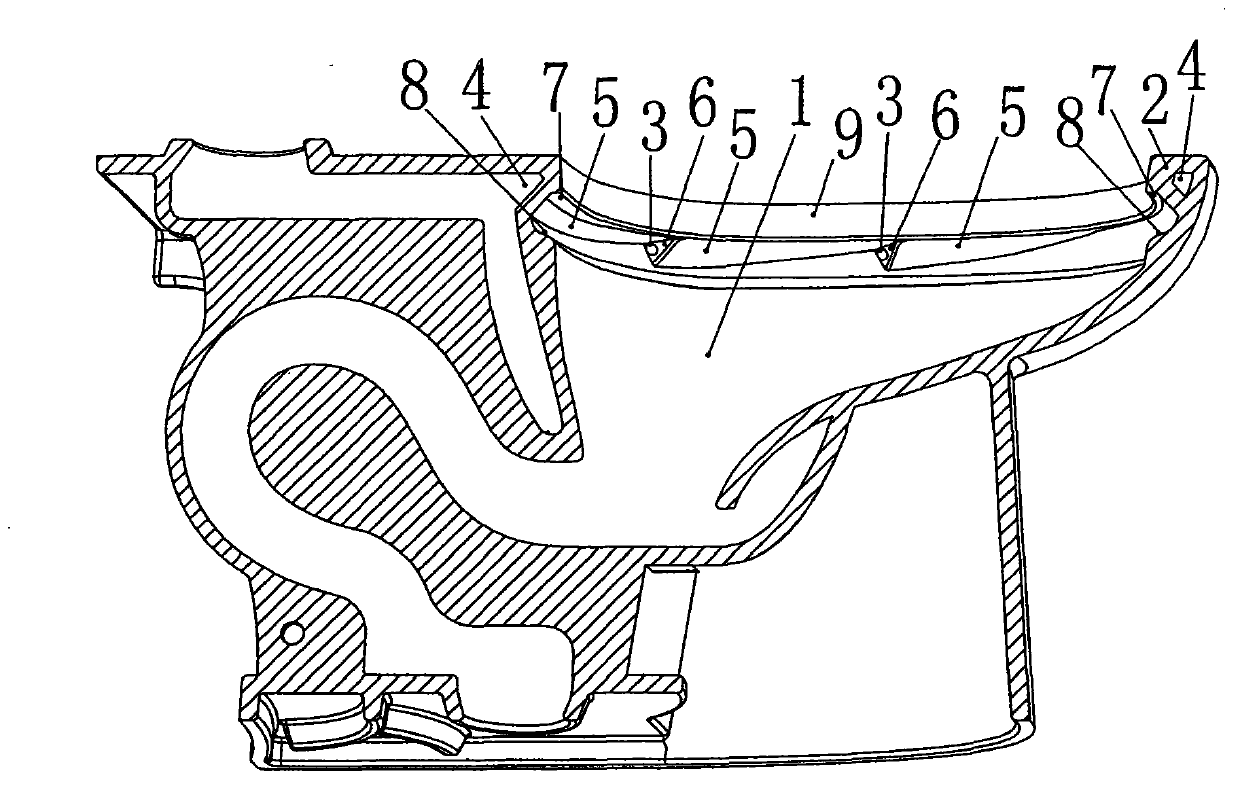

[0025] refer to image 3 , Figure 4 In the toilet, there are a bedpan 1 and a seat ring 2. The seat ring 2 has an inner surface 9, a water flow channel 4 inside, a connecting surface 7, a slope surface 5, and a perforated surface 6 in the lower part, and the lower part of the seat ring 2 is a non-flat surface as a whole. , the slope surface 5 and the perforated surface 6 are close to the inner wall of the bedpan 1, the slope surface 5 and the perforated surface 6 are combined to form a zigzag or wave shape, the slope surface 5 and the perforated surface 6 are in a ring shape along the inner wall of the bedpan 1, and the perforated surface 6 There is a cleaning hole 3, and the direction of the cleaning hole 3 is basically the same as the extending direction of the nearby slope surface 5; the connection surface 7 is used as a transition connection between the slope surface 5, the perforated surface 6 and the inner surface 9, and the connection surface 7 is The flat surface is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com