Wallboard assembling robot

A robot and wall panel technology, applied in construction, building structure, building material processing, etc., can solve the problems of low recognition of partition panels, high manual installation costs, affecting the promotion of partition panels, etc., and reduce installation costs. , easy to maintain, beneficial to the effect of cleaner production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

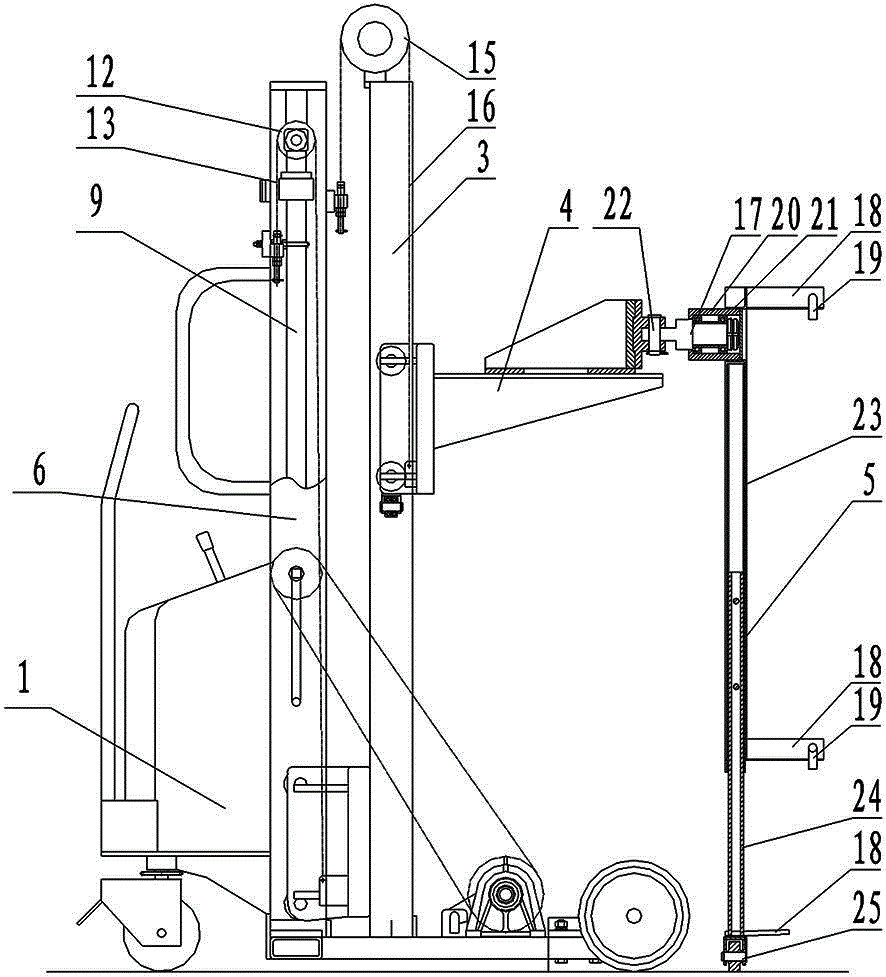

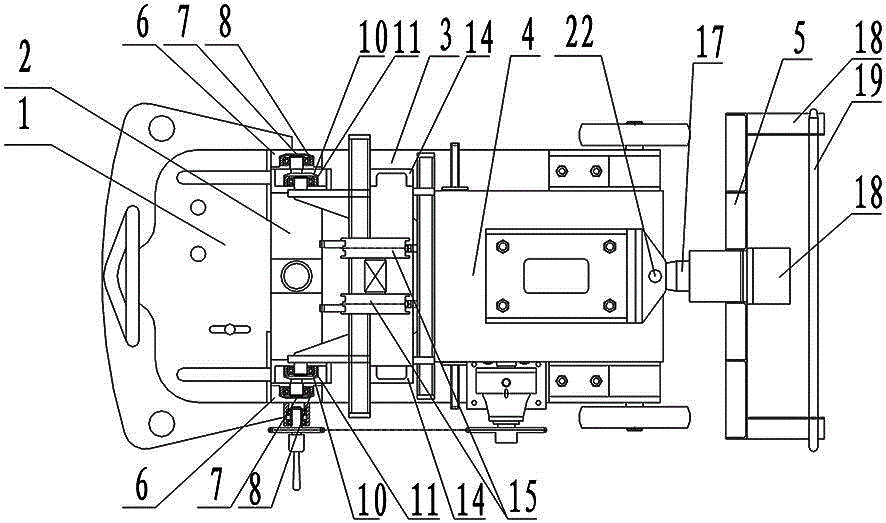

[0016] Such as figure 1 , figure 2 As shown, the wall panel assembly robot includes a frame 1 with walking wheels at the bottom, a lifting frame 2, a sliding frame 3, a lifting seat 4 and a hanging basket 5, and the frame 1 is provided with two relatively parallel columns. 6. There is a guide rail A7 extending in the vertical direction inside the column 6, and both sides of the lifting frame 2 are slidingly arranged in the guide rail A7 of the corresponding column 6, and both sides of the lifting frame 2 are provided with guide rails A7. The roller A8 of the roller A8 is slidably arranged in the guide rail A7 of the corresponding side column 6; the lifting hydraulic cylinder 9 arranged along the direction parallel to the guide rail A7 is fixedly arranged on the vehicle frame 1, and the piston rod o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com