Fluid-driven pumping unit and method of application thereof

A fluid-driven, application-method technology, applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc., can solve the problems of small energy conversion and large energy conversion loss, and achieve small energy conversion loss, stable load, and energy saving good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

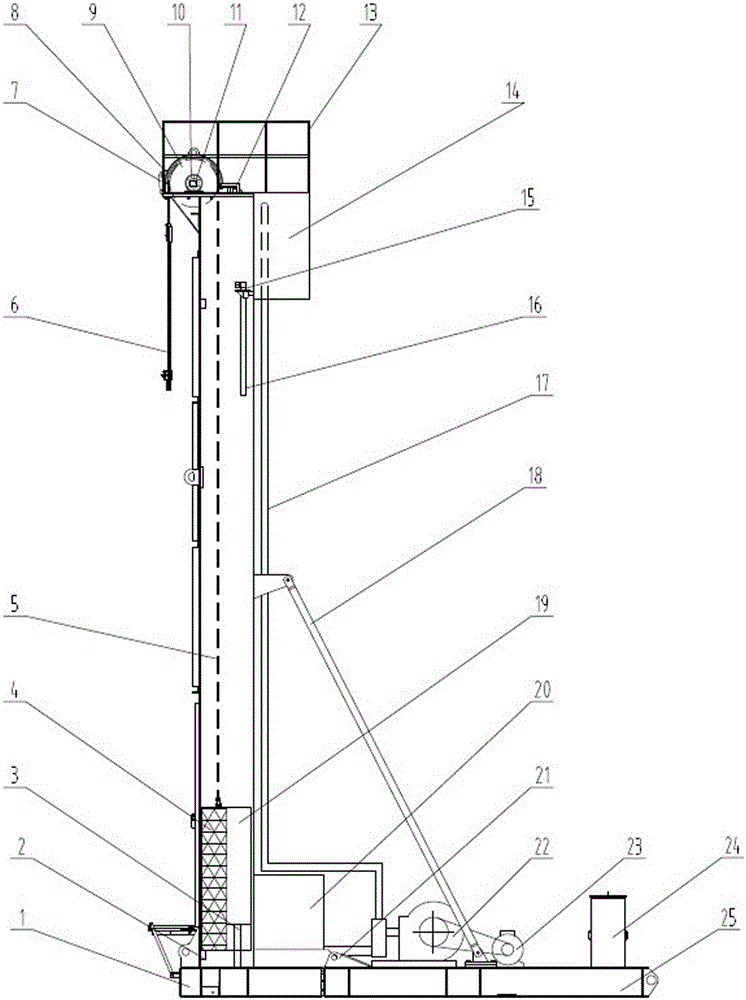

[0017] refer to figure 1 , a fluid-driven pumping unit, comprising a base assembly 25 and a frame assembly 1 connected thereto, with an oblique support rod 18 connected between them; a roller support 10 is installed on the top of the frame assembly, and a There is a drum 9, a belt 5 is wound on the upper surface of the drum 9, a speed detection device 11 is arranged on the drum shaft, and a brake device is installed on the drum 9, and the brake device includes a brake 8 and a brake drive device 12; the upper part of the frame assembly 1 The upper and lower fluid tanks 14, 20 are respectively fixed with the lower part, and the connection is established through the fluid lifting system 22 installed on the base assembly 25. The fluid lifting system 22 includes a pump (driven by a motor 23) and a liquid lifting tube 17. The upper part The bottom of the fluid box 14 is provided with a liquid conduit 16, on which an electromagnetic valve is installed; the frame assembly 1 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com