A cleaning device for the air inlet of a moisture exhaust fan

A technology of exhaust fan and cleaning device, which is applied to the components of pumping device for elastic fluid, mechanical equipment, machine/engine, etc. The frequency of manual maintenance of the filter screen, the reduction of production costs, and the effect of continuous and effective operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

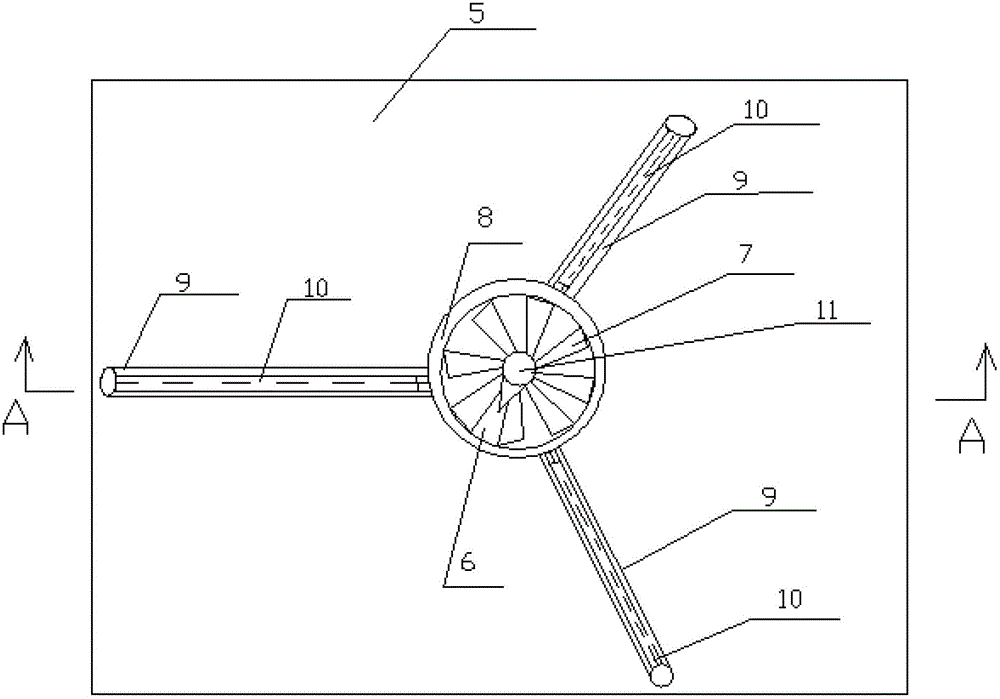

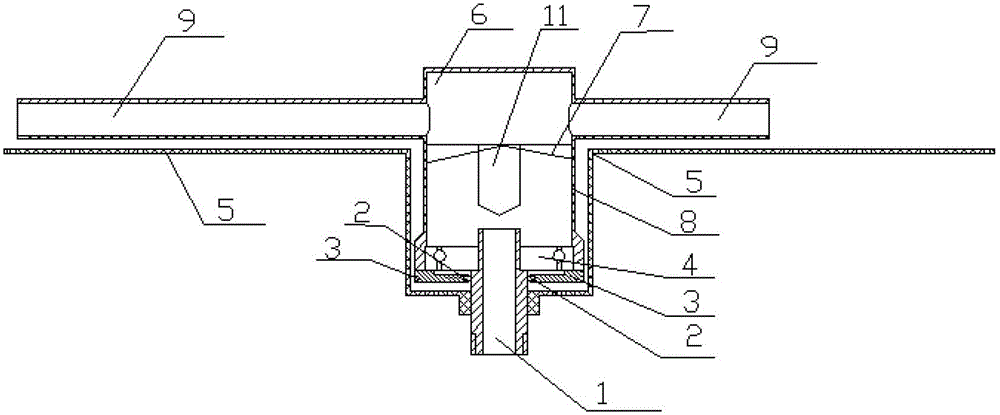

[0015] like figure 1 , figure 2 As shown, a cleaning device for the air inlet of the moisture exhaust fan according to the present invention includes an air inlet nozzle 1, a cleaning wheel 6 and a bearing I4, the air inlet nozzle 1 is fixed at the air inlet of the moisture exhaust fan, and the bearing I4 is set on the inlet The upper end of the air nozzle 1, the lower end is provided with an end cover 3 and a sealing strip 2; the cleaning wheel 6 includes a blade 7, a ring sleeve 8 and a cleaning pipe 9, one end of the blade 7 is movably connected to the bearing II11, and the other end is fixed on the ring sleeve On the inner surface of 8, the cleaning pipe 9 is evenly distributed on the outer surface of the ring sleeve 8, and the bottom of the cleaning pipe 9 is provided with a groove 10, and the ring sleeve 8 is closely matched with the bearing I4.

[0016] According ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com