Disk brake mechanism of tractor

A disc brake and tractor technology, applied in the field of brake mechanism, can solve problems such as reduced friction effect, hidden safety hazards, insensitive braking effect, etc., and achieve the effects of reducing poor brakes, convenient maintenance, and good sewage discharge capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

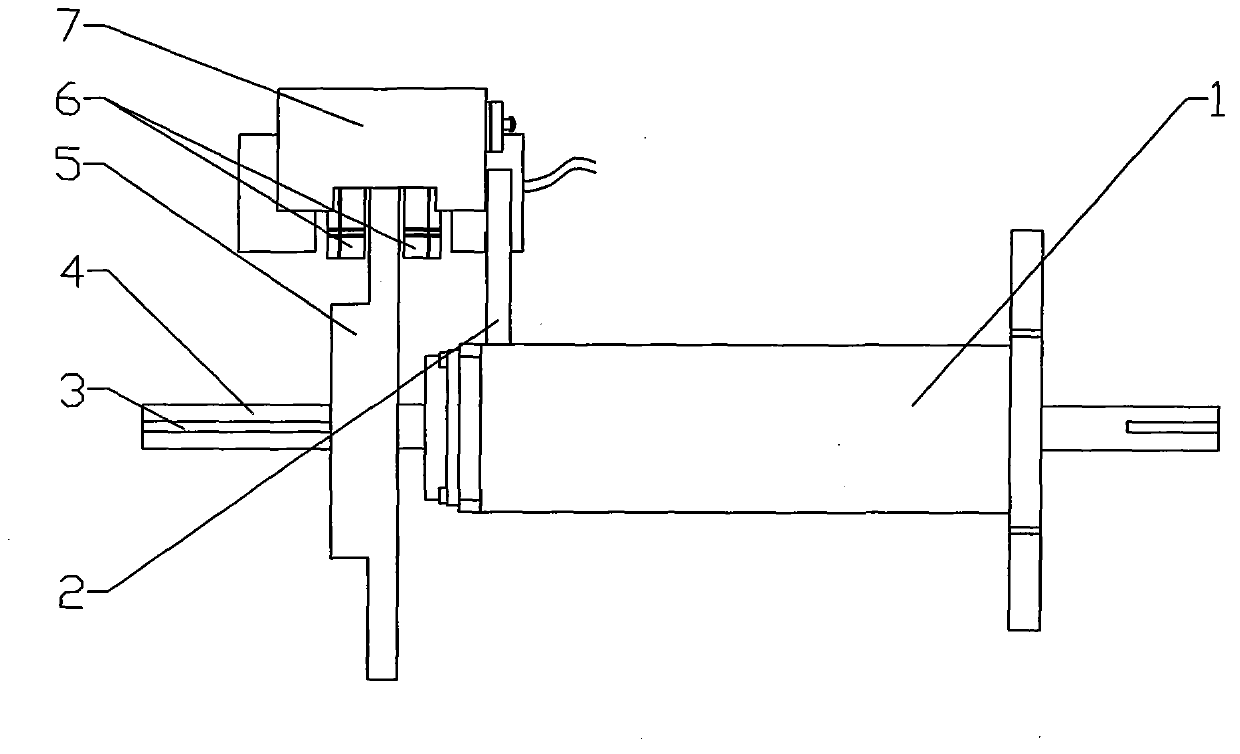

[0012] Embodiment: As shown in the accompanying drawings, a tractor disc brake mechanism includes a brake caliper 7, a brake pad 6 and a brake disc 5. The brake caliper 7 is fixed on the shaft sleeve 1 through the fixed bracket 2, the brake caliper 7 is connected with the hydraulic pump through a hydraulic pipe, the brake caliper 7 has a brake pad 6, the half shaft 4 is provided with a keyway 3, and the brake disc 5 is keyed to the half shaft. On the axle 4, the axle shaft 4 and the brake disc 5 rotate together.

[0013] When the tractor brakes, the hydraulic pump transmits the hydraulic oil to the brake caliper 7 through the hydraulic pipe, and the hydraulic oil generates pressure to press the brake pad 6 to the brake disc 5, thereby producing a braking effect. Because the brake disc 5 and the axle shaft 4 are keyed together, the braking effect also acts on the axle shaft 4, so that the axle shaft 4 slows down and rotates or even stops rotating, so the wheels will be braked, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com