Measuring instrument and measuring method of small-size inner hole chamfering depth

A measuring instrument and technology of small size, applied in the direction of mechanical depth measurement, etc., can solve the problems affecting the degree of fit of parts and the performance of structural parts, and achieve the effect of improving the degree of fit, improving the performance and convenience of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

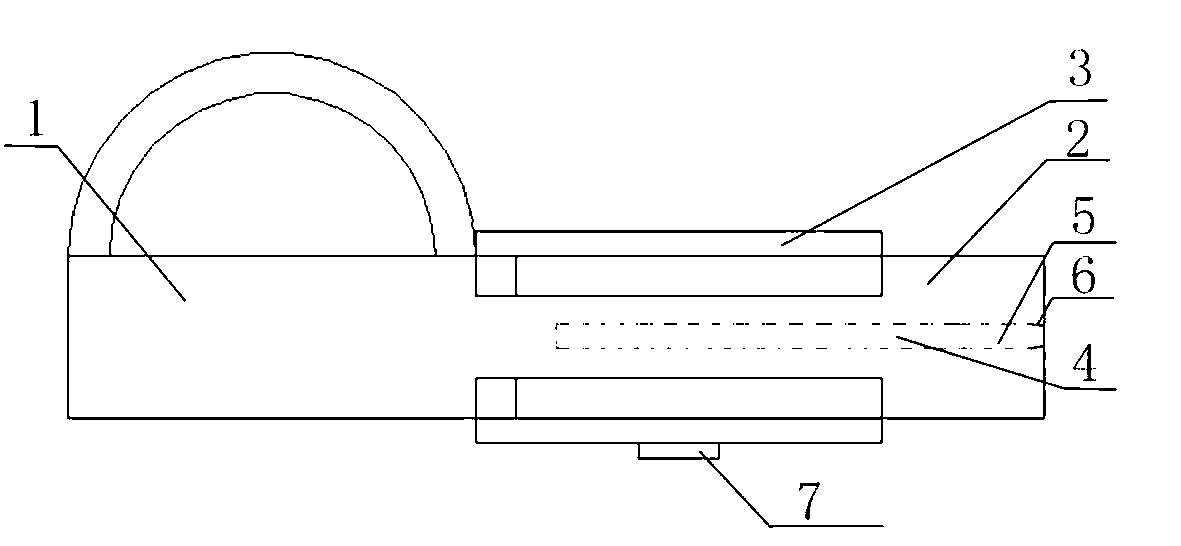

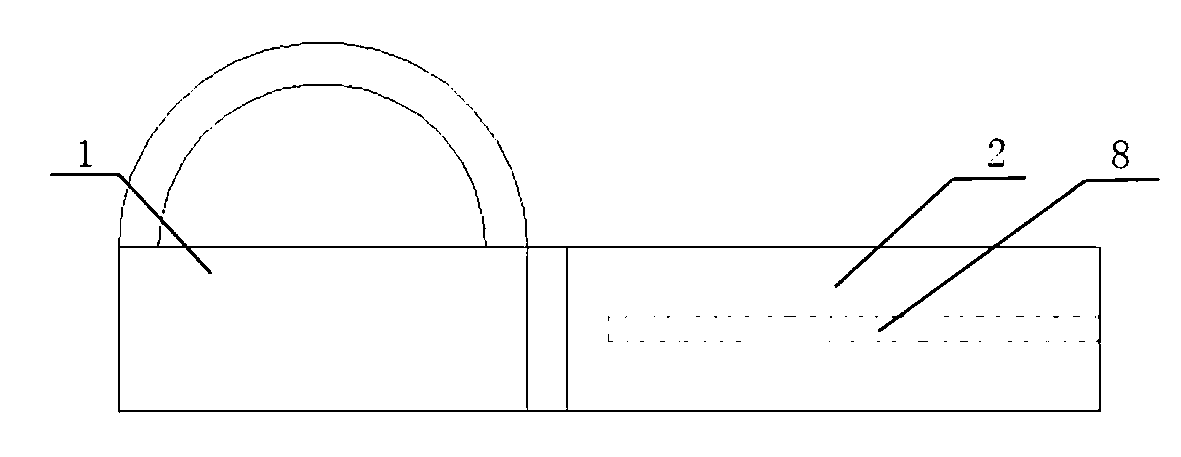

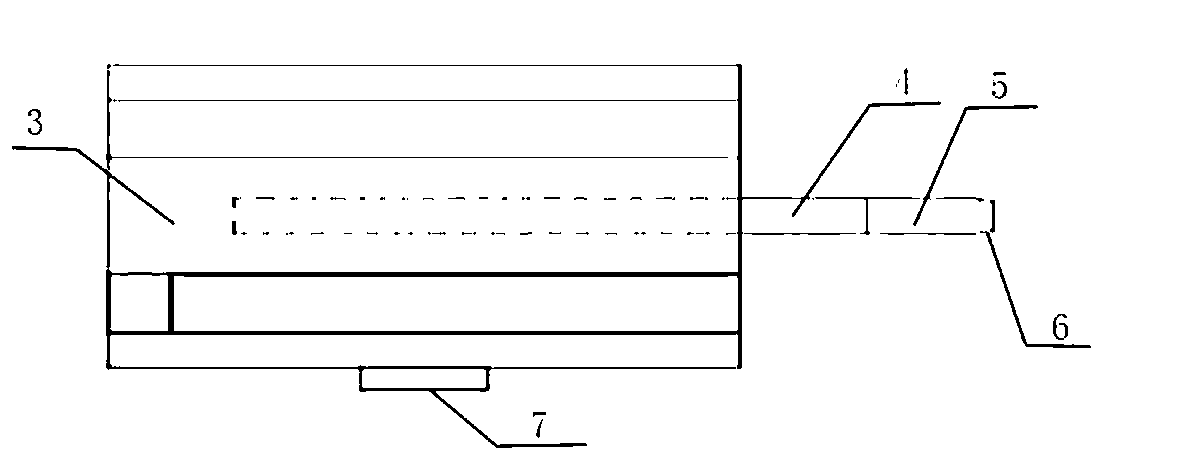

[0026] In order to further describe the present invention, introduce below in conjunction with accompanying drawing of description:

[0027] The measuring instrument and measuring method for the chamfering depth of small-sized inner holes are characterized by the following steps:

[0028] Prepare measuring instruments and products to be tested;

[0029] According to the inner diameter of the inner hole of the product, the measuring instrument selects a suitable measuring head. The diameter of the top circle of the measuring head is 0.0002mm larger than the inner diameter of the inner hole of the product (the dimensional accuracy of the measuring head can be determined according to the product accuracy);

[0030] ③ Fix the measuring head on the measuring rod on the measuring instrument, and zero the measuring instrument;

[0031] ④ Place the product to be tested on the right side of the measuring instrument with the right hand, with the chamfered part to the left, keep the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com