Apparatus for the manufacture of double-walled pipes

A composite tube and tube seat technology, applied in the direction of applications, tubes, rigid tubes, etc., can solve the problems that can only be connected or disconnected as a whole, inaccurate vacuum control, and cannot be vacuum controlled

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

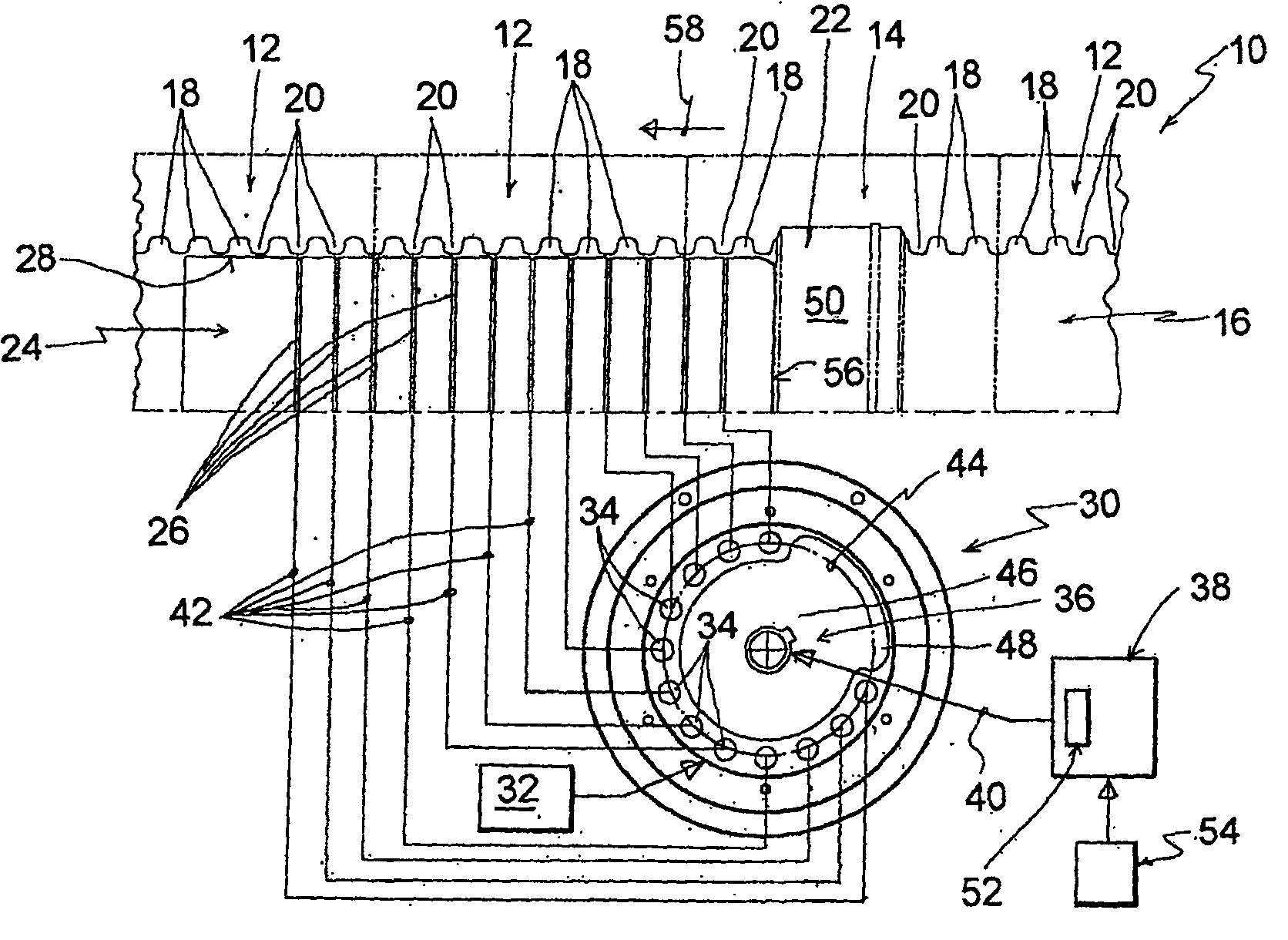

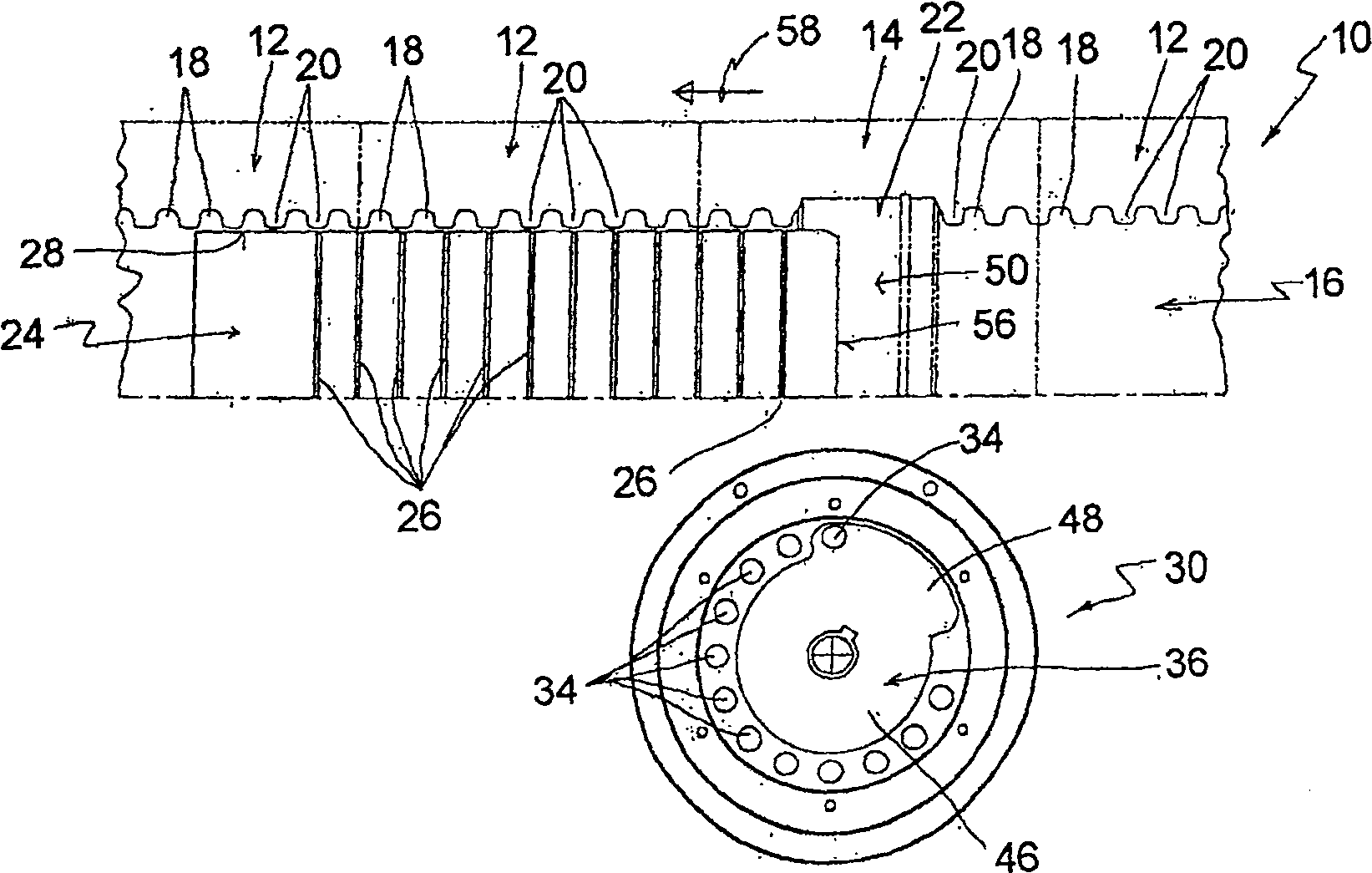

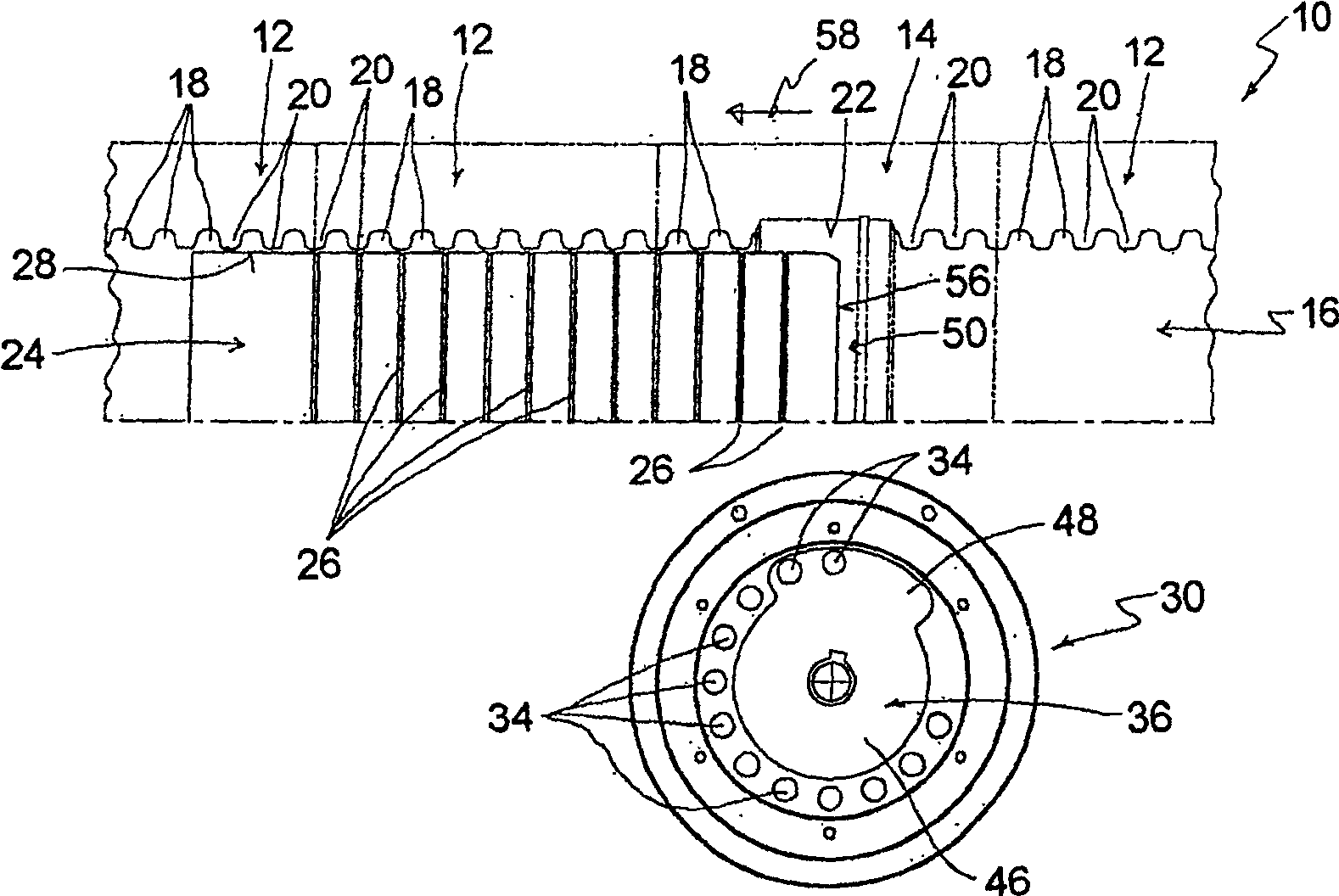

[0022] figure 1 Important details of the device 10 for producing a double-walled composite pipe according to the invention are schematically shown, namely the forming clip halves 12 and 14 . The figure shows three forming clip halves 12 of a row of forming clips. Corresponding forming clip halves 12, 14 are located in a second row (not shown) of forming clip halves opposite this row of forming clip halves 12, 14 so as to form forming channels for the manufacture of double wall composite pipes 16.

[0023] The profiled clip halves 12 positioned opposite each other along the profiled channels 16 are alternately designed with transverse grooves 18 and transverse ribs 20 .

[0024] Forming clip half 14— figure 1 Only one forming clip half 14 is shown in FIG. 2 - designed to have an inner contour 22 corresponding to the base portion of the double-wall composite pipe to be produced. The inner contour 22 adjoins the transverse groove 18 and the transverse ribs 20 on both sides. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com