One-dimensional retractable target device and feature point calibrating method thereof

A production method and telescopic technology, which is applied to measurement devices, optical devices, instruments, etc., can solve the problems of unseen targets and difficult to achieve, and achieve the effect of small occupied space, simple production, and guaranteed accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

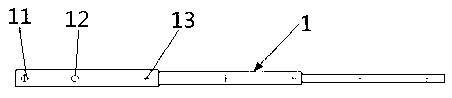

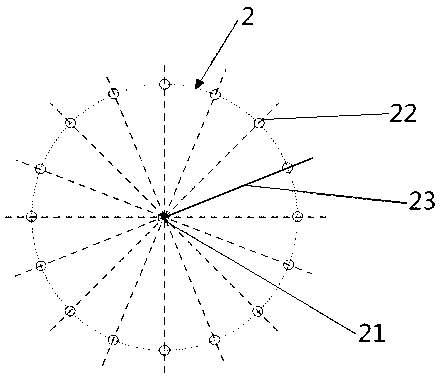

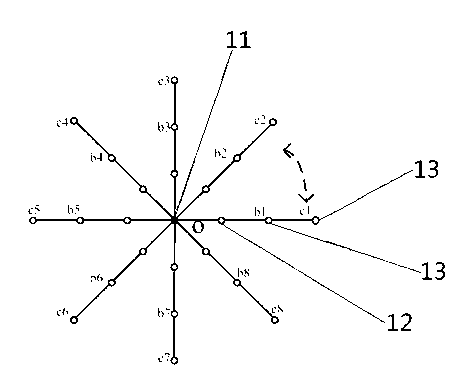

[0040] like figure 1 , figure 2 , image 3 As shown, the one-dimensional retractable target device includes a calibration rod 1 and a chassis 2; the calibration rod 1 includes a fixing hole 11, a positioning hole 12 and a plurality of marking points 13; the calibration rod 1 is composed of multiple metal tubes of different lengths and thicknesses It is connected to be telescopic; the fixing hole 11 is set at the very end of the calibration rod 1; the distance between the marking points 13 is equal, and the number of marking points can be increased according to the needs; the chassis 2 includes a central screw hole 21, a plurality of equal circles Screw hole 22 and reference line 23; the radius of the chassis 2 is equal to the distance between the positioning hole 12 and the fixed hole 11; the central screw hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com