Device and method for measuring phase delay temperature characteristic of optical fiber quarter wave plate

A wave plate phase and temperature characteristics technology, applied in the direction of testing optical performance, etc., can solve the problems that the error model cannot be established, the measurement accuracy of the optical fiber current transformer is affected, and there is no measurement method for the phase delay temperature characteristic of the optical fiber 1/4 wave plate. Achieve the effects of eliminating optical power fluctuations, ensuring detection sensitivity, and accurate online compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

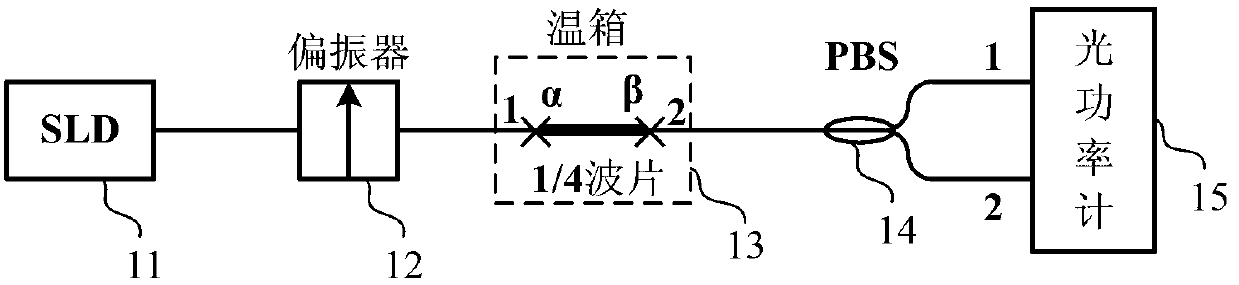

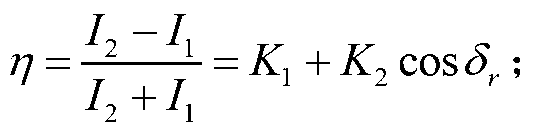

[0016] Such as figure 1 As shown, the optical fiber 1 / 4 wave plate phase delay temperature characteristic measurement device provided by the present invention includes a broadband light source 11 , a polarizer 12 , a 1 / 4 wave plate 13 and a polarization beam splitter (PBS) 14 . figure 1 In the shown embodiment, SLD is selected as the wide-spectrum light source 11 . The light emitted by the SLD11 is polarized by the polarizer 12 and becomes linearly polarized light, and one end of the measured 1 / 4 wave plate 13 is fused with the output pigtail of the polarizer 12 at an angle α, so that the linearly polarized light generated by the polarizer 12 is at 1 The / 4 wave plate 13 is decomposed into two beams of orthogonal linearly polarized light, and the two beams of orthogonally linearly polarized light are respectively transmitted along the fast axis and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com