Method for estimating lateral force of tire

A lateral force and tire technology, which is applied in automobile tire testing and other directions, can solve problems such as slow calculation speed, complex algorithm, and large amount of calculation, and achieve the effect of less fitting parameters, good real-time performance, and improved observation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

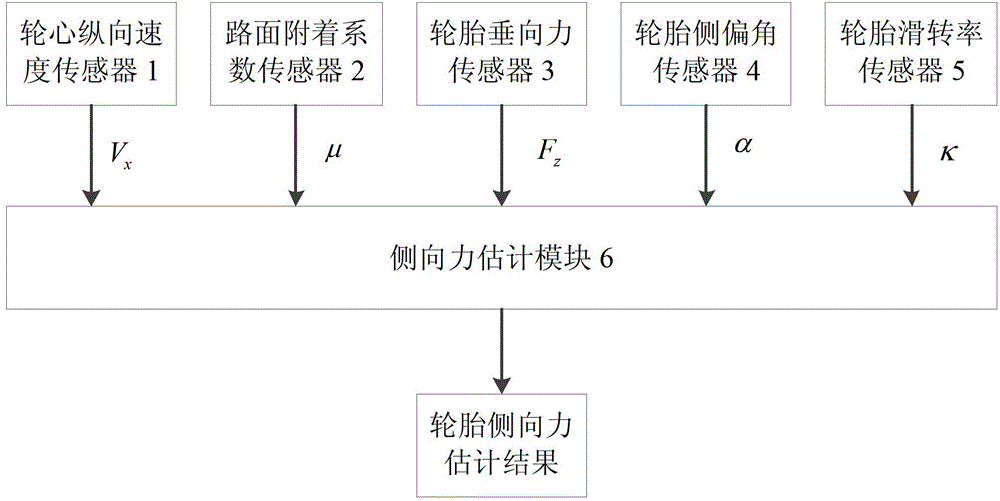

[0013] Such as figure 1 As shown, the tire lateral force estimation method of the present invention comprises the following steps:

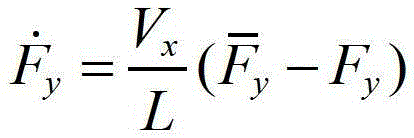

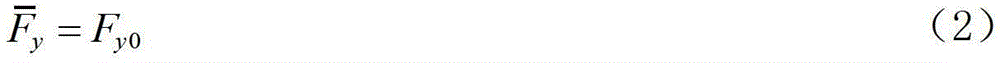

[0014] 1. Set up a tire lateral force estimation system, which includes a wheel center longitudinal velocity sensor 1 arranged in the vehicle controller for collecting the wheel center longitudinal velocity of the tire; a road surface adhesion coefficient arranged in the vehicle state observer Sensor 2 is used to collect the road surface adhesion coefficient; a tire vertical force sensor 3 arranged on the suspension spring is used to collect the vertical force of the tire; a tire slip angle sensor 4 arranged on the vehicle state observer is used to for collecting the side slip angle of the tire; a tire slip rate sensor 5 arranged at the vehicle controller for collecting the slip rate of the tire; a lateral force estimat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com