Device for processing large-size flange surface

A large-scale flange and surface processing technology, which is applied in the direction of metal processing equipment, manufacturing tools, milling machine equipment details, etc., can solve problems such as the impact of processing accuracy, and achieve the effects of improving processing accuracy, shortening processing time, and flexible use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

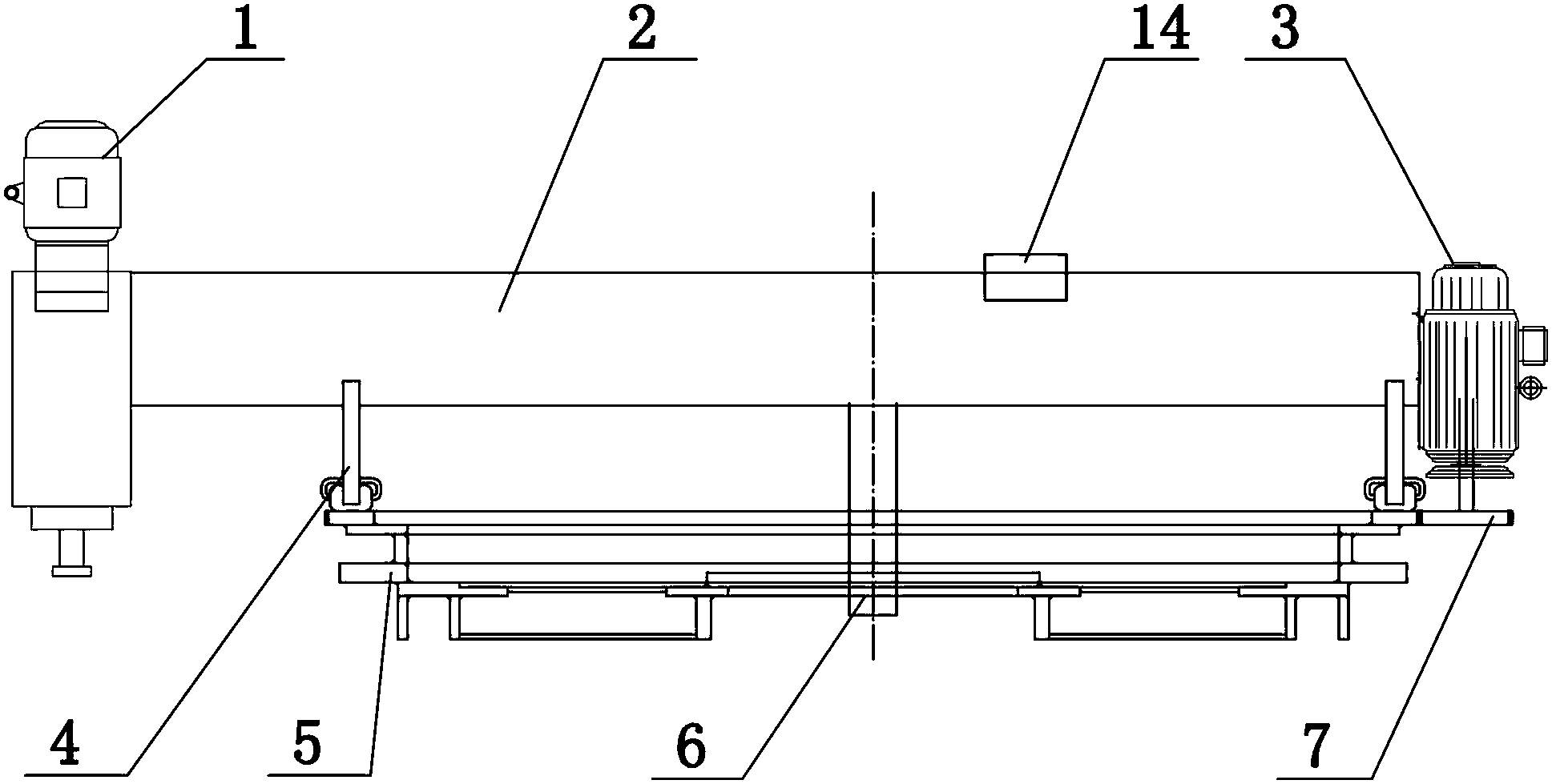

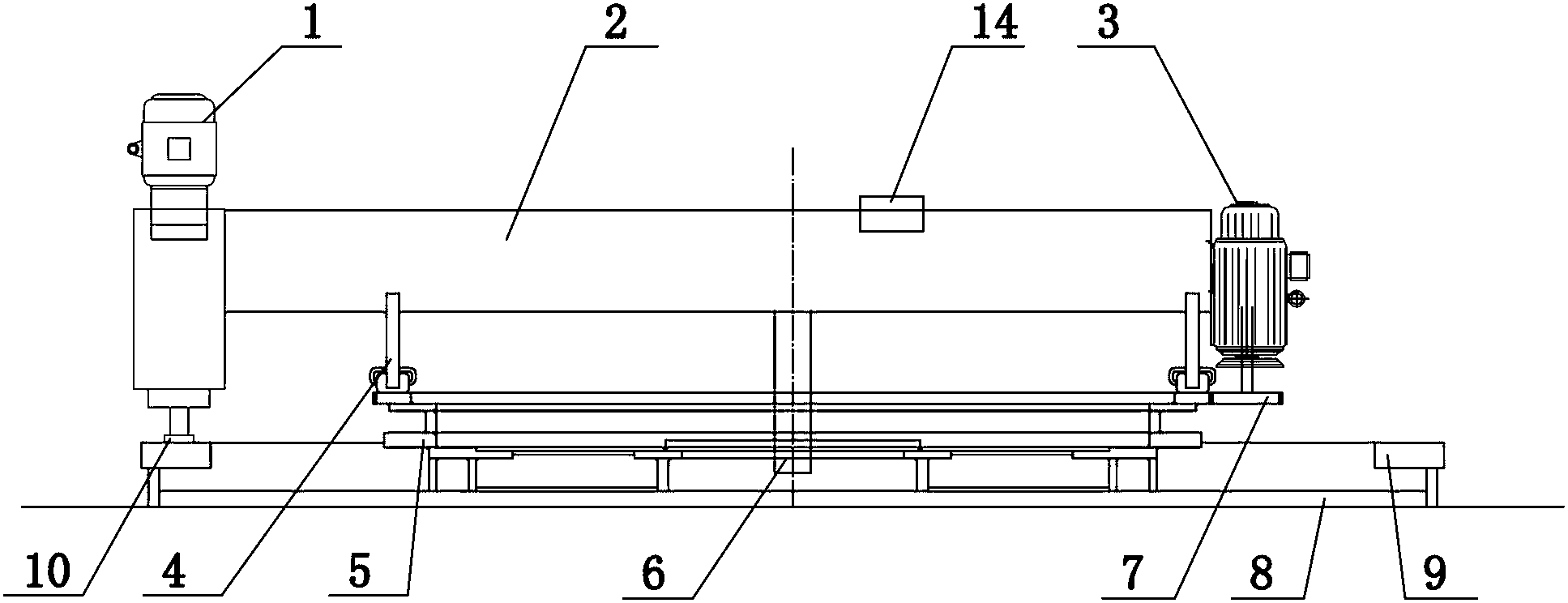

[0025] Such as figure 1 , 2 Among them, a device for large-scale flange surface processing, including a milling cutter 10 driven by a milling cutter driving device 1, the milling cutter 10 and the milling cutter driving device 1 are installed at one end of the processing arm 2 for driving the processing arm 2 The rotating arm rotation driving device 3 is installed on the other end of the processing arm 2; the milling cutter driving device 1 in this example includes a milling cutter rotating driving device and a feed driving device, and in a preferred solution, the milling cutter driving device 1 passes through the telescopic arm (11) is movably connected with the processing arm 2 through guide rails. Since the structure of the milling cutter driving device 1 can be obtained in the prior art, it will not be repeated here.

[0026] A main shaft 6 is provided near the middle of the processing arm 2, and the processing arm 2 rotates around the main shaft; this structure ensures ...

Embodiment 2

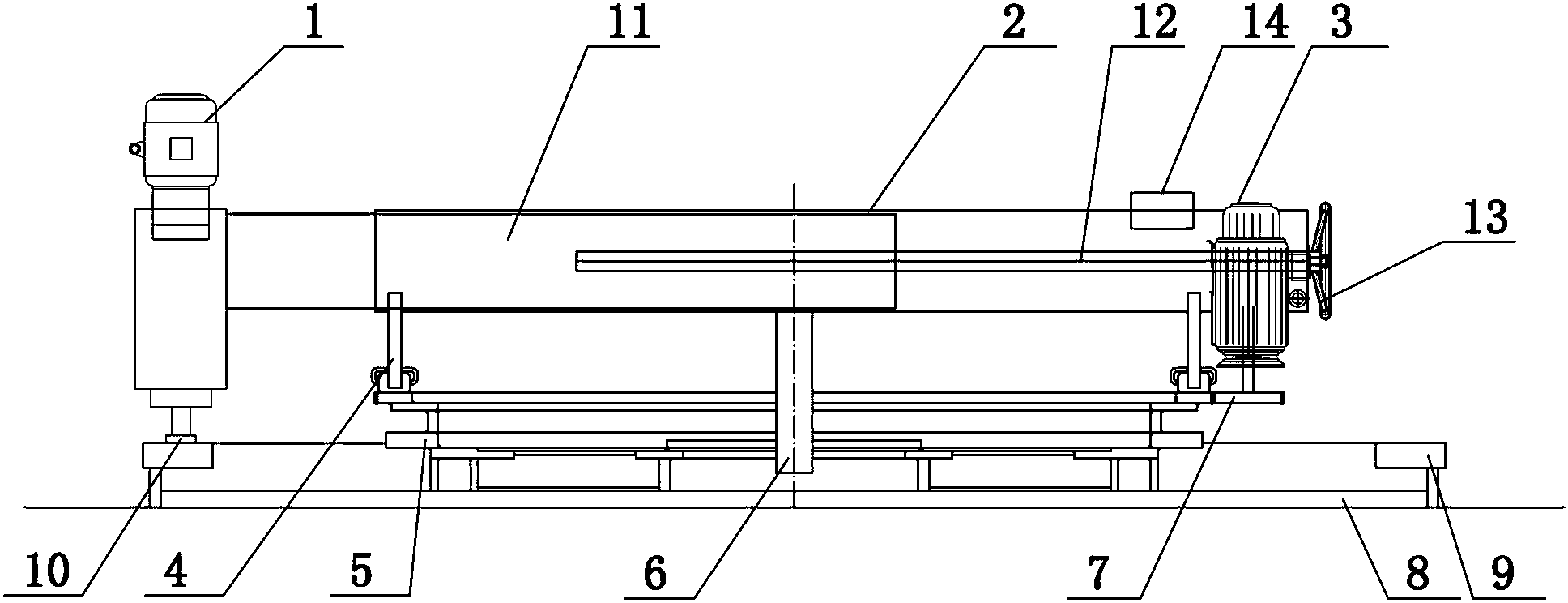

[0037] Such as image 3 Among them, a device for large-scale flange surface processing, including a milling cutter 10 driven by a milling cutter driving device 1, the distance between the milling cutter driving device 1 and the processing arm 2 can be adjusted to the main shaft 6 active connection. The milling cutter driving device 1 is installed at one end of the telescopic arm 11 , the telescopic arm 11 is movably connected with the processing arm 2 through a guide rail, and the other end of the telescopic arm 11 is provided with a nut connected with the screw rod 12 . The free end of the screw rod 12 is provided with a hand wheel 13 .

[0038] A main shaft 6 is provided near the middle of the processing arm 2, and the processing arm 2 rotates around the main shaft;

[0039] The position close to the edge of the flange 9 to be processed on the processing arm 2 is also provided with a tightening adjustment roller 4 for adjusting the level of the processing arm 2 .

[0040]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com