Scrap tire wheel hub hydraulic removal machine and method

A tire and hydraulic technology, used in punching machines, presses, manufacturing tools, etc., can solve problems such as hidden safety hazards, high labor intensity of operators, low production efficiency, etc., to prevent rupture, avoid piston rod deformation, and easy to deform. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

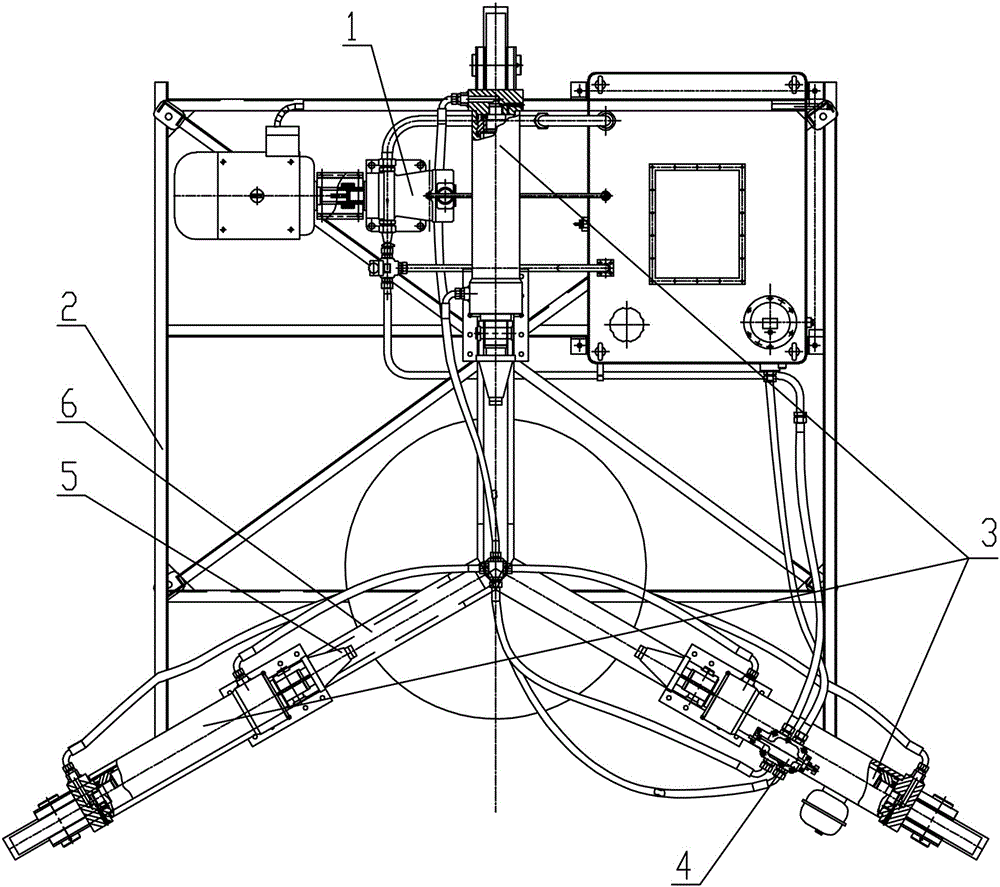

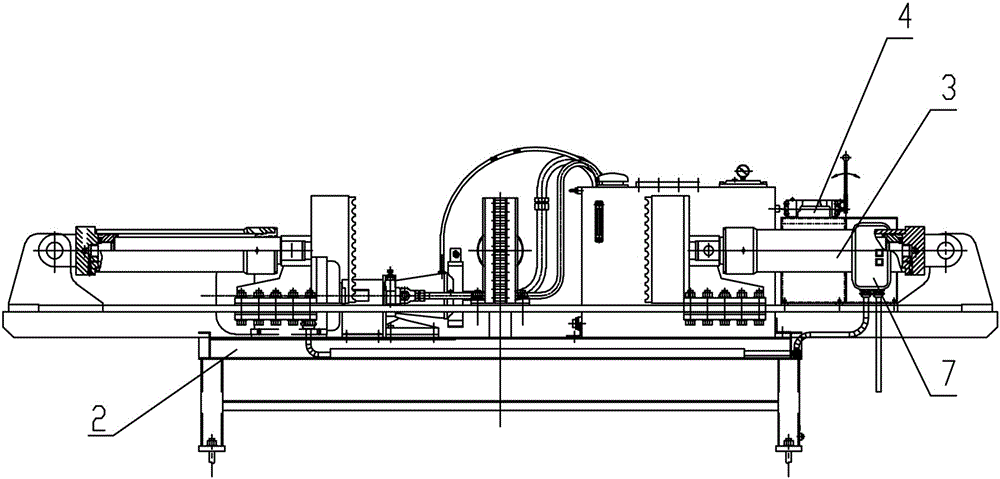

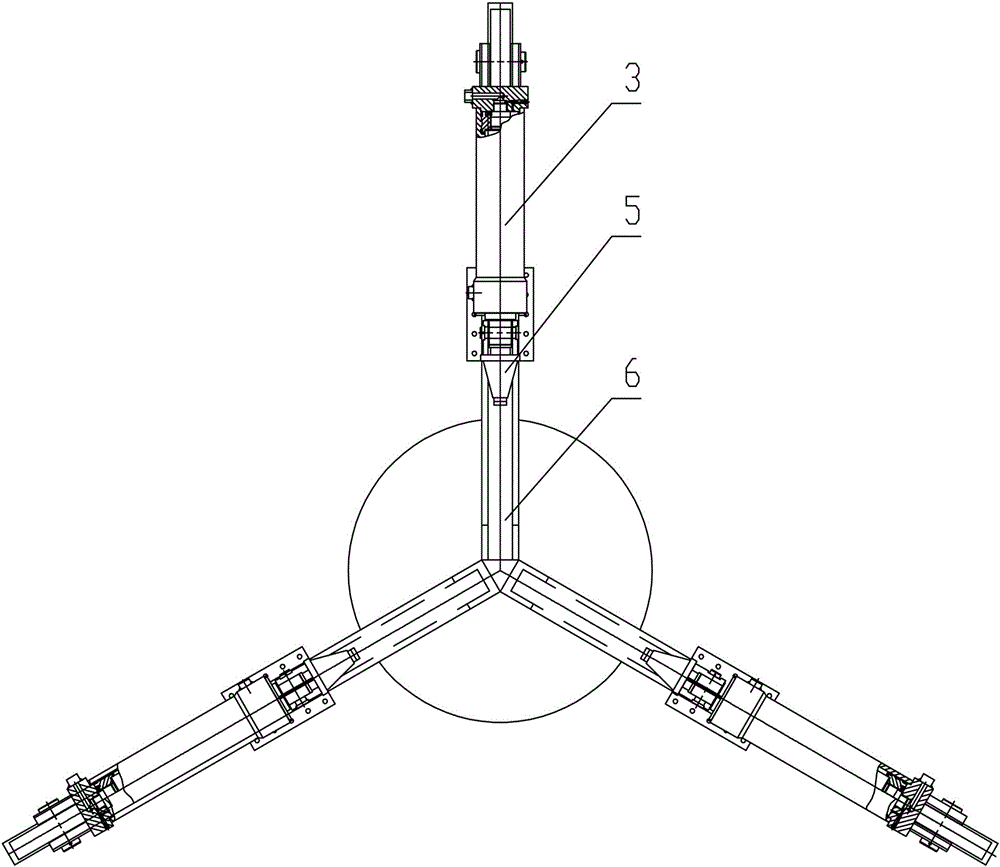

[0031] Such as figure 1 , 2 Among them, a hydraulic wheel removal machine for scrap tires, including a frame 2, the frame 2 is made of channel steel, angle steel, I-beam and other section steel and steel plates wedge-shaped welded and machined, and the upper end faces of the frame are circumferentially opposite to each other. There are 3-4 hydraulic cylinders 3, and the oil circuit of the hydraulic cylinder 3 is connected with the hydraulic drive device 1 through the reversing valve 4;

[0032] One end of the hydraulic cylinder 3 close to the outer edge is fixedly connected to the frame 2. In this example, a bolt is used for connection. The end near the center of the circle is provided with a pressure head 5, and the hydraulic cylinder 3 and the pressure head 5 are also connected with a bolt. Spaces for accommodating tires are left between each indenter 5 , and radially arranged guide rails 6 are provided on the upper end surface of the frame 2 corresponding to the indenter 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com