Patents

Literature

33results about How to "Easy to deal with separately" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

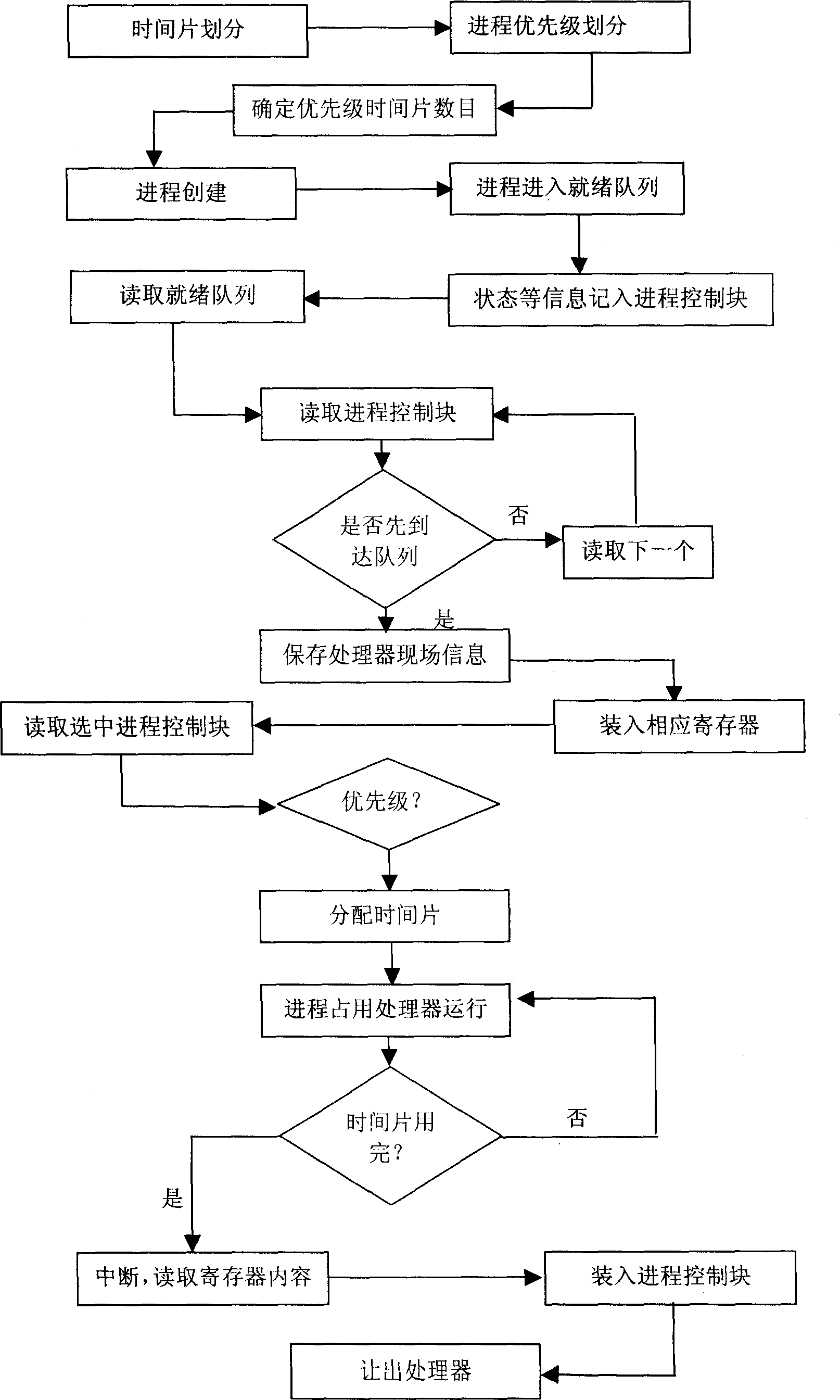

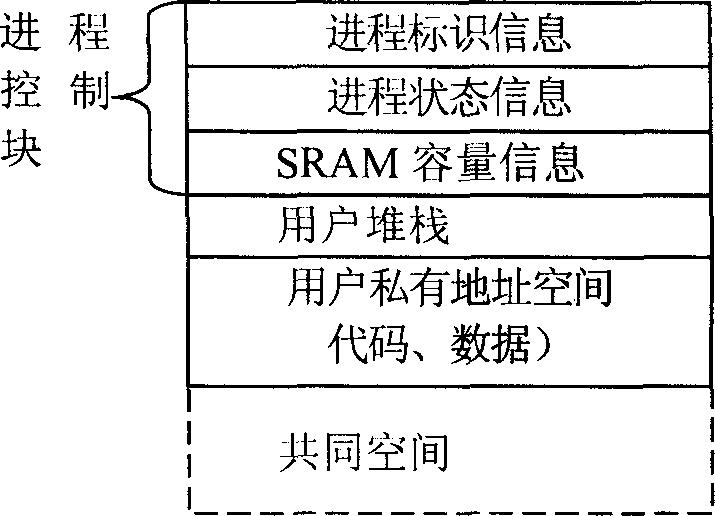

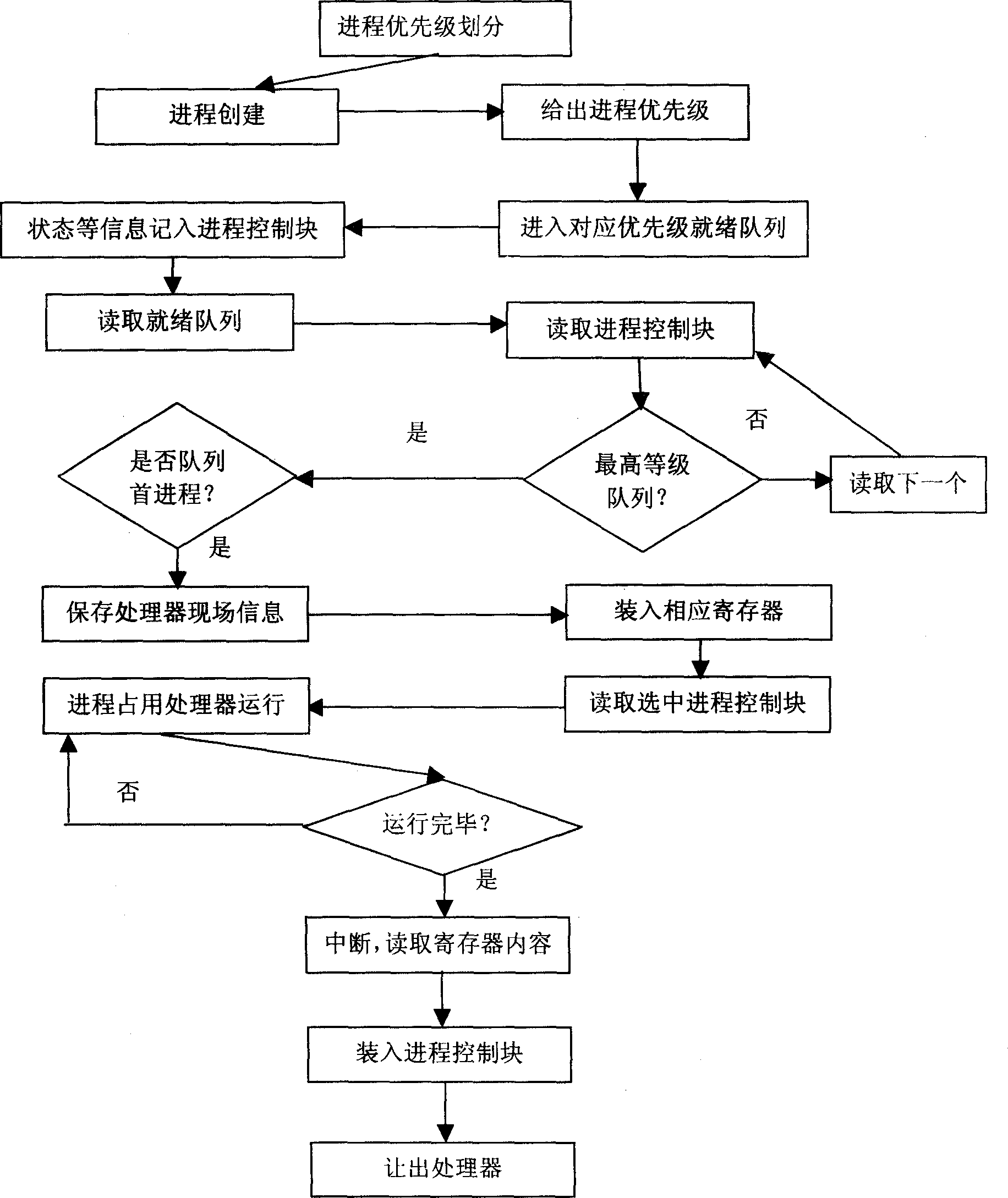

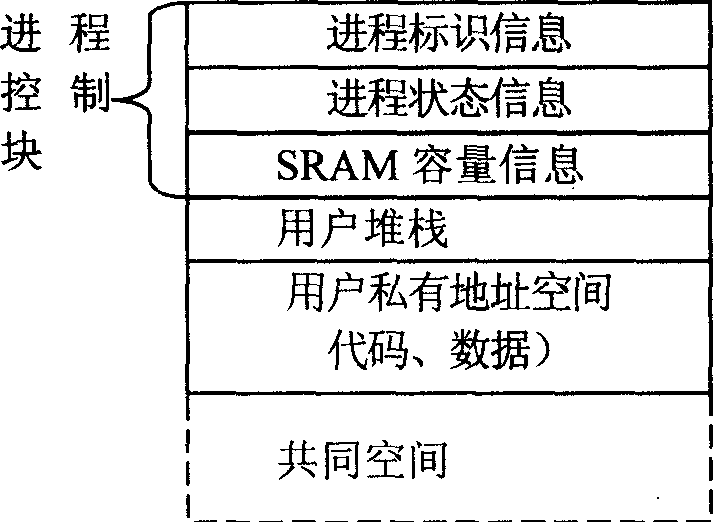

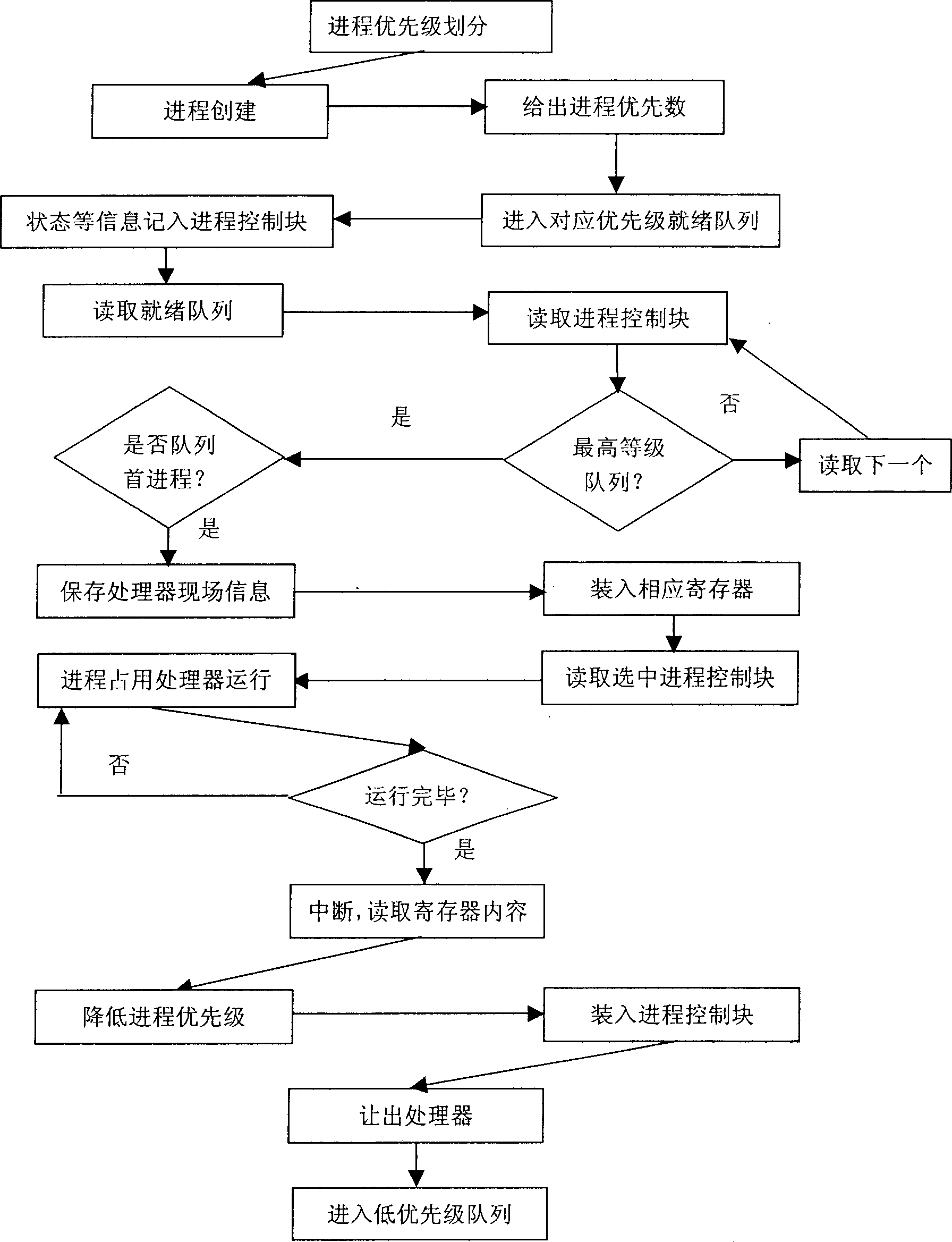

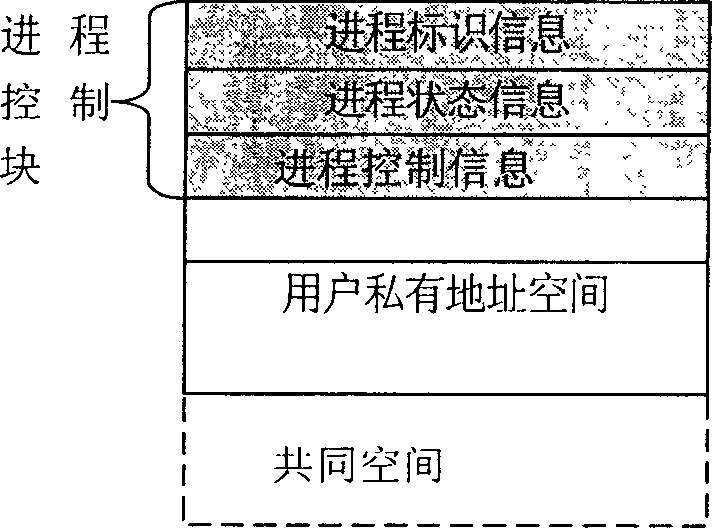

Method for realizing process priority-level round robin scheduling for embedded SRAM operating system

InactiveCN1851652AFast dispatch responseEasy to implementResource allocationOperational systemClock rate

The present invention relates to embedded system process scheduling field for providing an embedded type SRAM operation system process priority scheduling implementation method. It contains recording state of a process, according to processor clock rate defining one suitable time span as time slice, dividing processor time into multiple equal time slice, progress grade dividing, travel time slice distribution, processor distribution and retrieve processor. Said method easy realizes, is in favor of respectively processing to different progress, at the same time said method has high response speed process scheduling to SRAM when progress has higher cpu use rate. Said invented method can prevent peripheral equipment progress occupying processor for long time.

Owner:ZHEJIANG UNIV

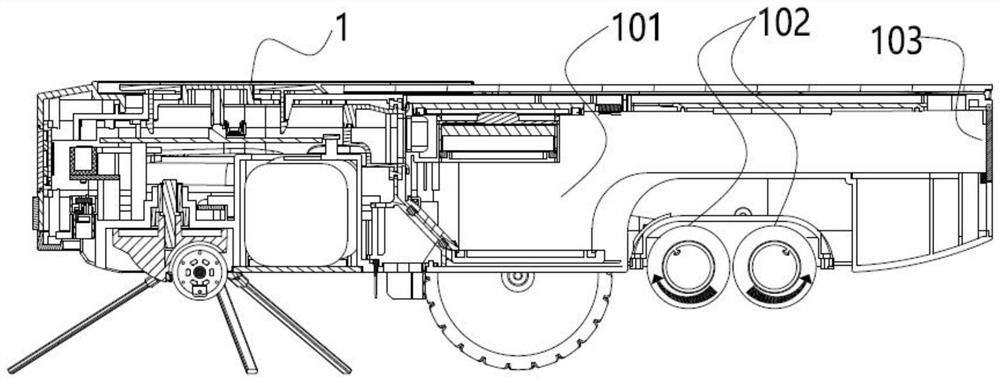

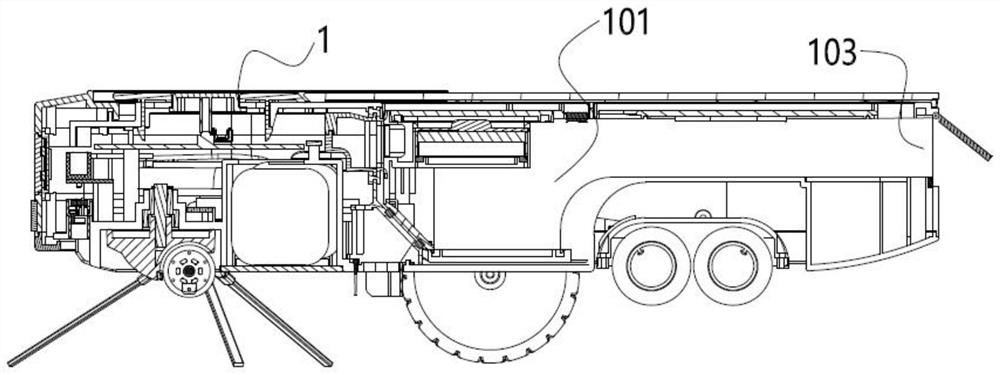

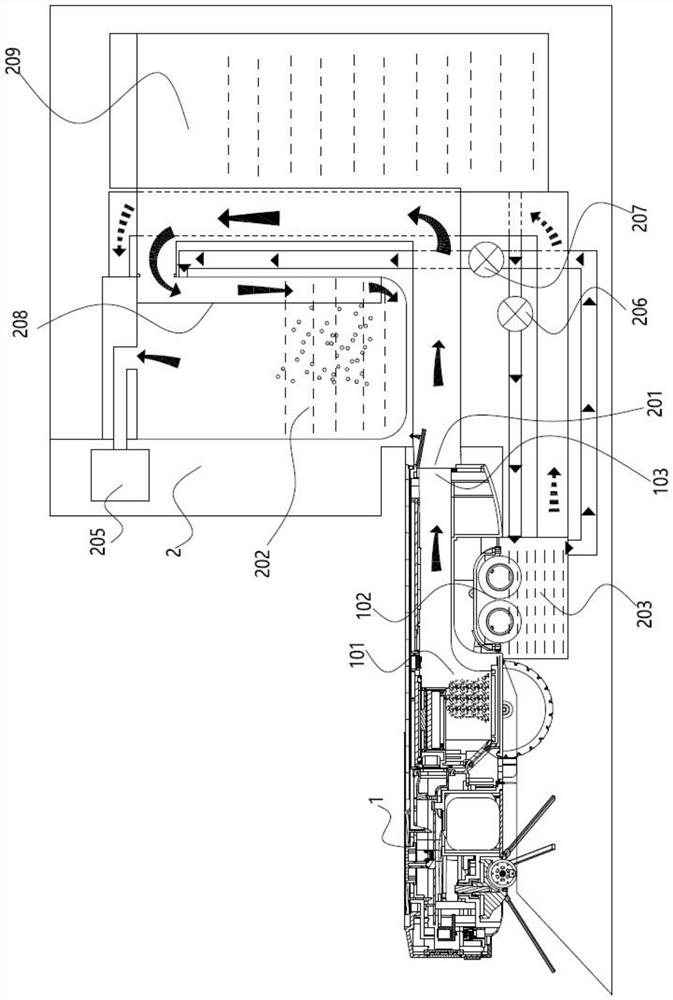

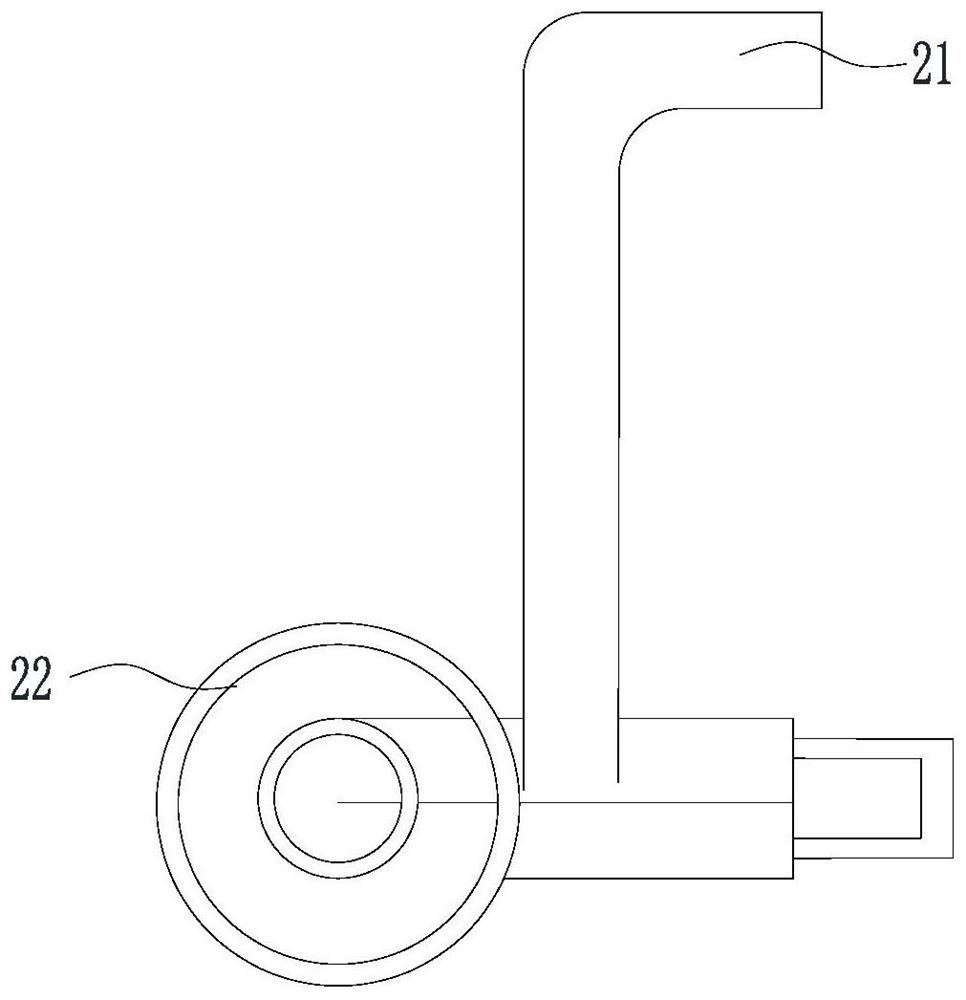

Control method of cleaning robot system

PendingCN112386181AEasy Pour DisposalSmall dump handlingCarpet cleanersFloor cleanersRobotic systemsSuction force

A control method of a cleaning robot system comprises a cleaning robot and an integration station, wherein the integration station is arranged to be an independent part relative to the cleaning robot.The method comprises the steps: the cleaning robot walks to the integration station and stops; a dust discharging opening in the cleaning robot corresponds to a dust collecting opening in the integration station in position, the dust discharging opening is connected with a garbage cavity in the cleaning robot, the dust collecting opening is connected with the dirt collecting box, and meanwhile, the cleaning part is located in the cleaning area; when the power mechanism is started to work, the garbage cavity and the cleaning area communicate with the dirt collecting box, and garbage in the garbage cavity and cleaning liquid in the cleaning area are sucked into the dirt collecting box at the same time under the suction effect of airflow to be mixed and collected; and when the working duration of the power mechanism reaches the first preset duration, the power mechanism stops working. According to the scheme, the problems of complex base station structure, high cost and serious dust raising caused by the fact that a disposable cloth bag or a multi-step hierarchical filtering structure is arranged for a filtering system of an existing base station are solved.

Owner:杭州匠龙机器人科技有限公司

Method for realizing process priority scheduling for embedded SRAM operating system

InactiveCN1851651AFast dispatch responseEasy to implementResource allocationOperational systemEmbedded system

The present invention relates to embedded system process scheduling field for providing an embedded type SRAM operation system process priority scheduling implementation method. Said method includes recording state of a process, dividing process priority, progress select, processor distribution and retrieve processor. Said method easy realizes, is in favor of respectively processing to different progress, at the same time said method has high response speed process scheduling to SRAM when progress has higher cpu use rate.

Owner:ZHEJIANG UNIV

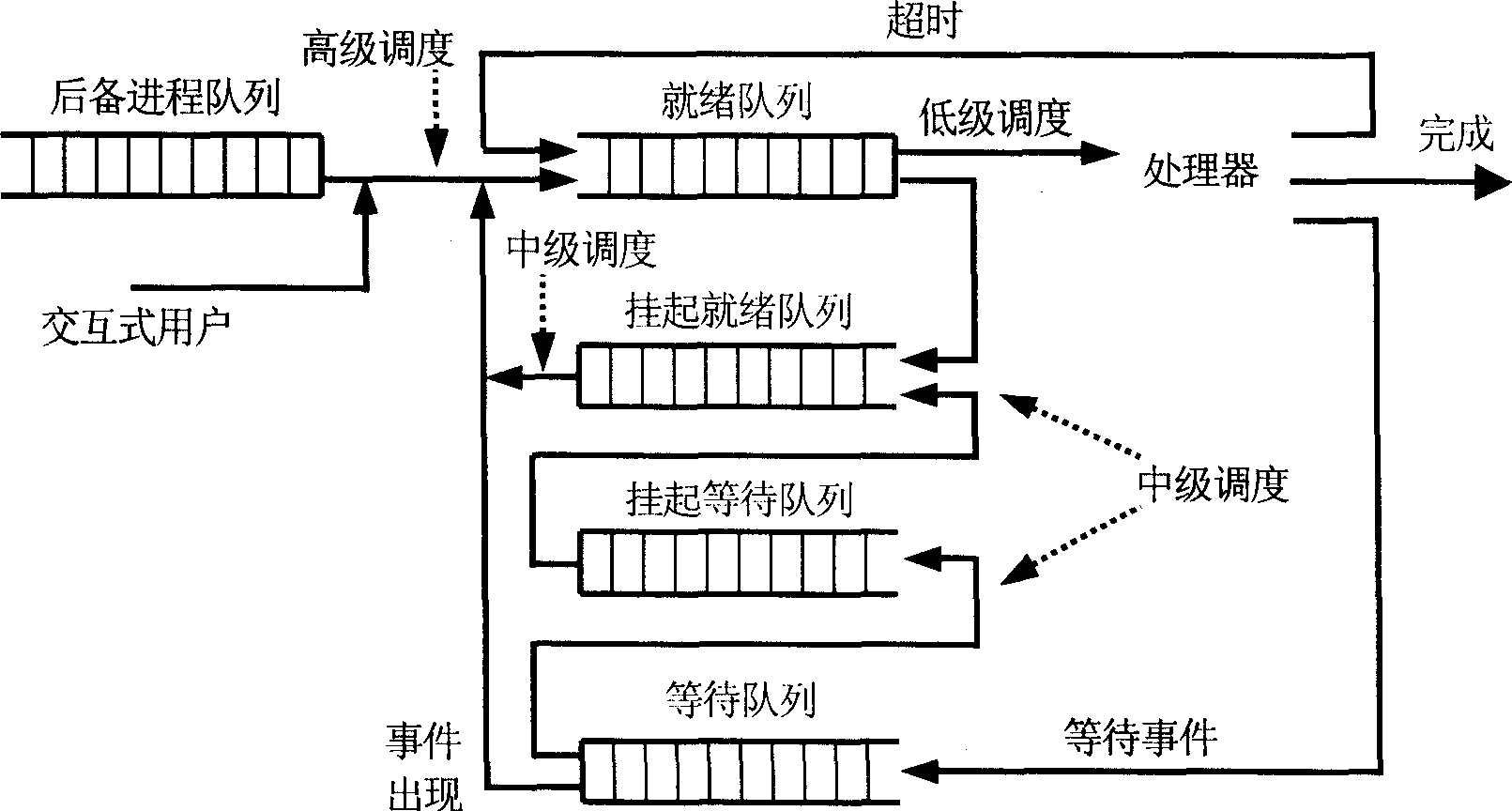

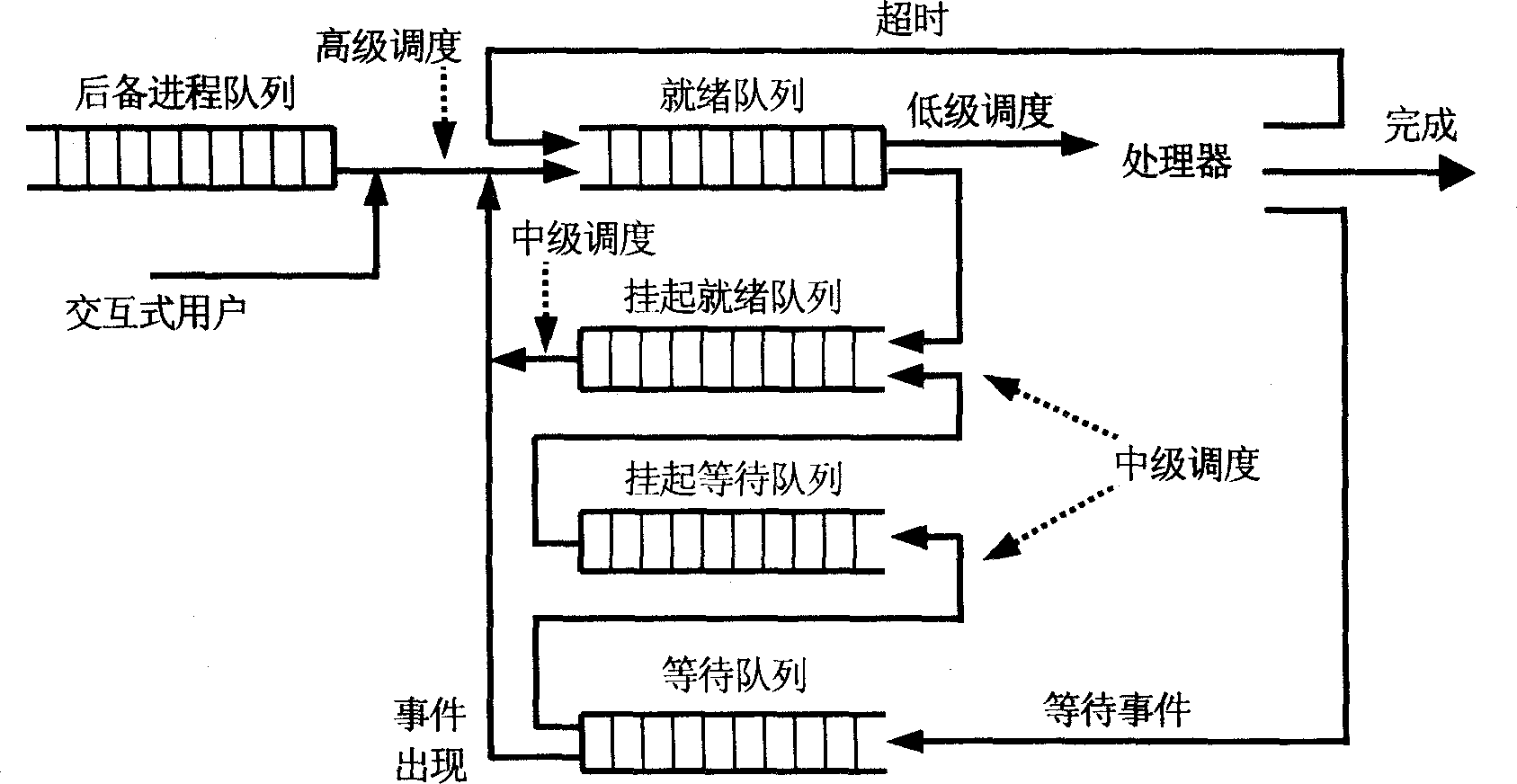

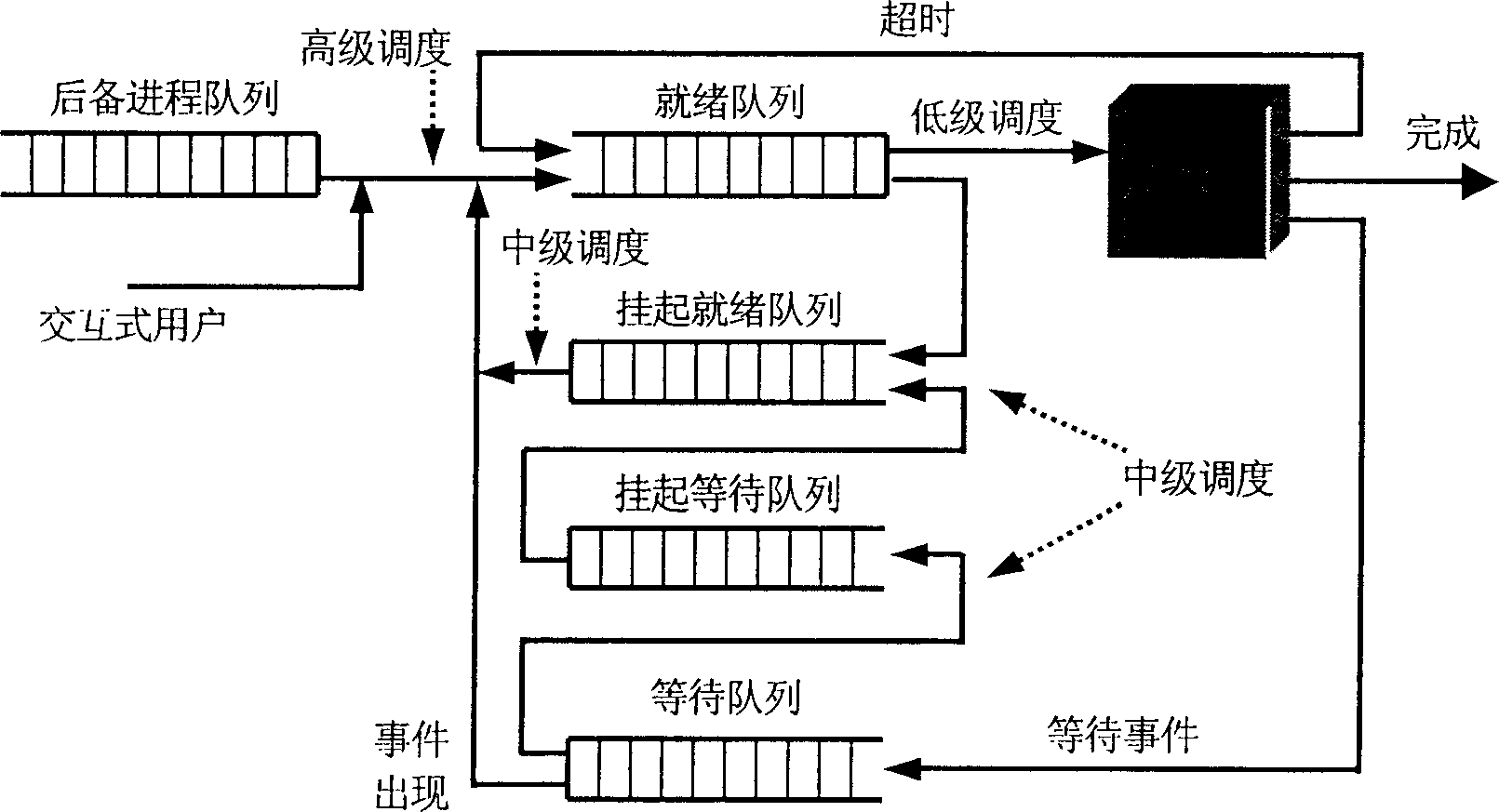

Method for implementing process multi-queue dispatching of embedded SRAM operating system

InactiveCN1825288AFast dispatch responseIncrease occupancyProgram initiation/switchingOperational systemProcessor scheduling

The invention discloses a method for realizing multi-queue process control for an embedded SRAM operating system, dividing ready process into two or multiple stages in the operating system, and correspondingly establishing two or multiple ready process queues for the system, and ordinarily allocating higher-priority queues to shorter time slices. And the processor control firstly selects available processor process from high-priority ready process queue each time and selects the process from lower-priority ready process queue only when no process is available. And the method can provide a good process control performance.

Owner:ZHEJIANG UNIV

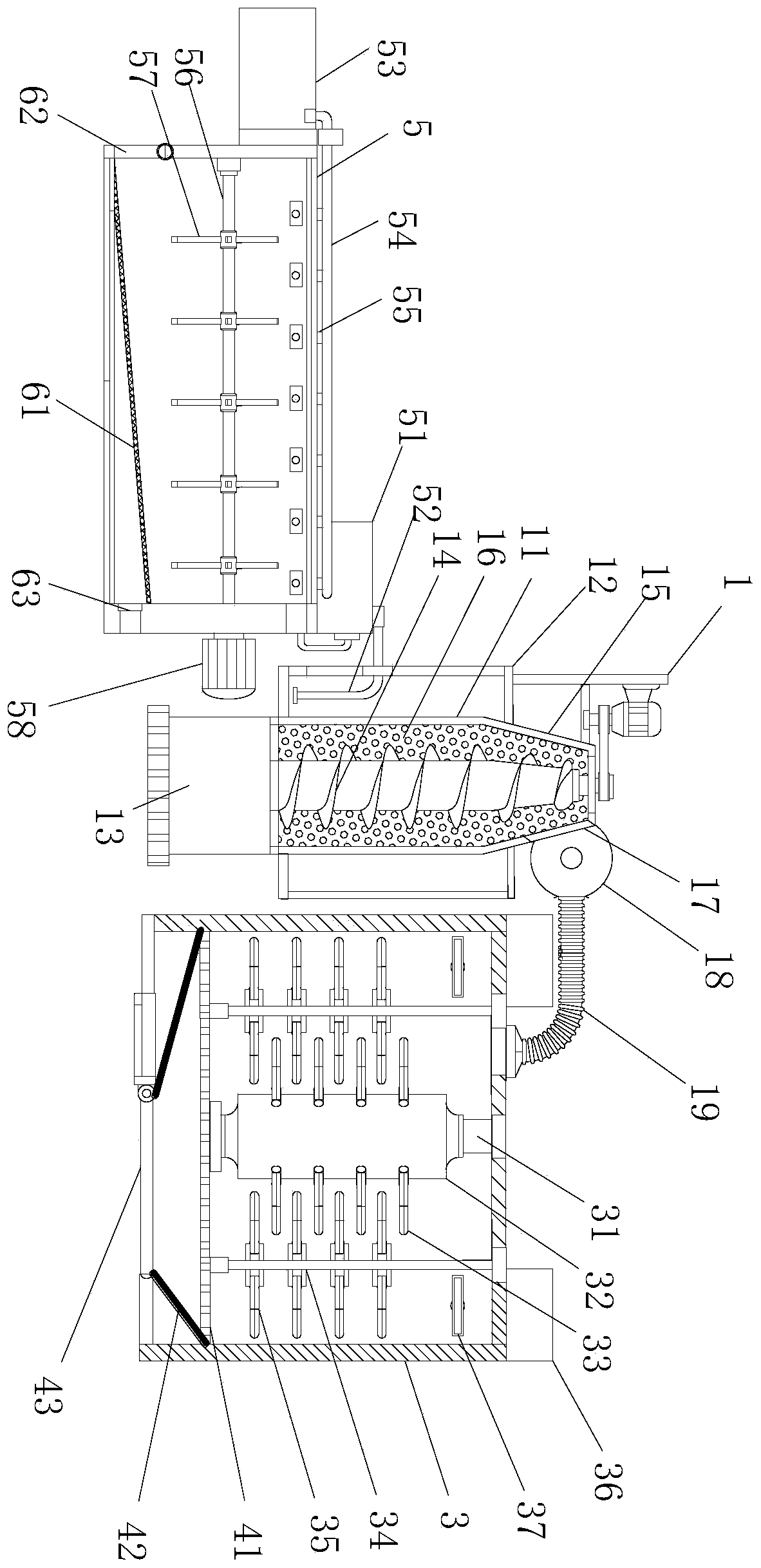

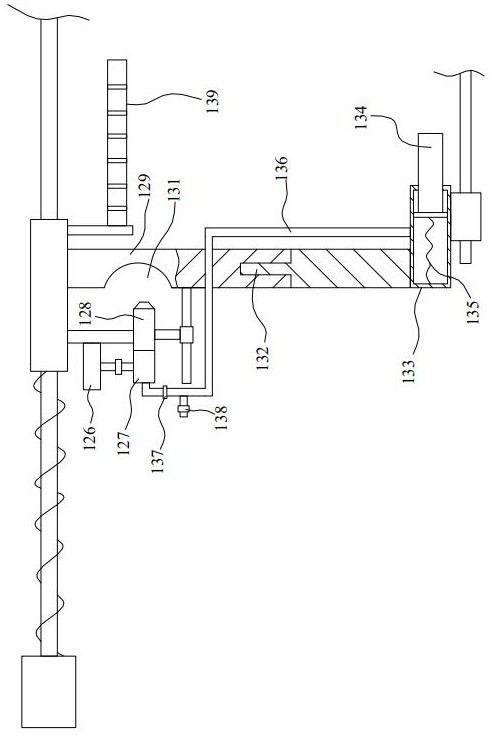

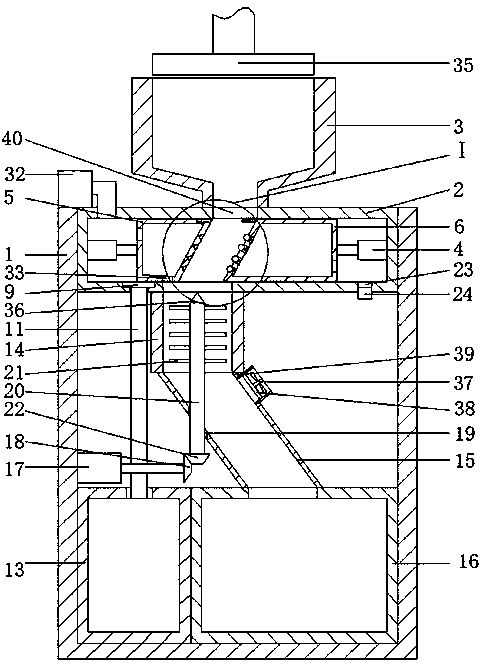

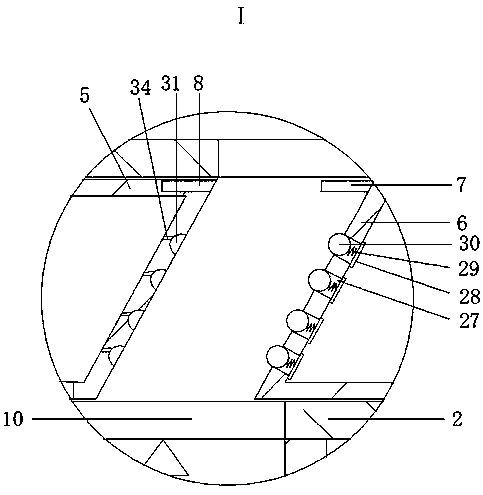

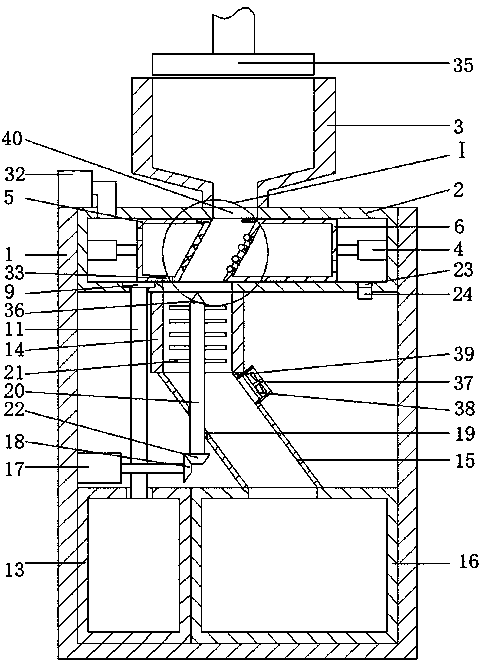

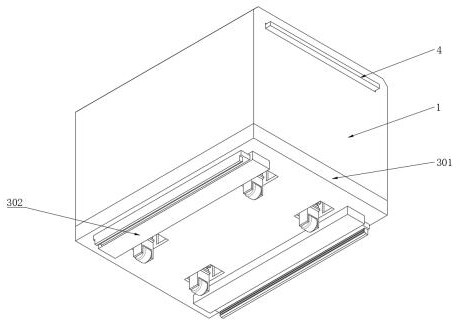

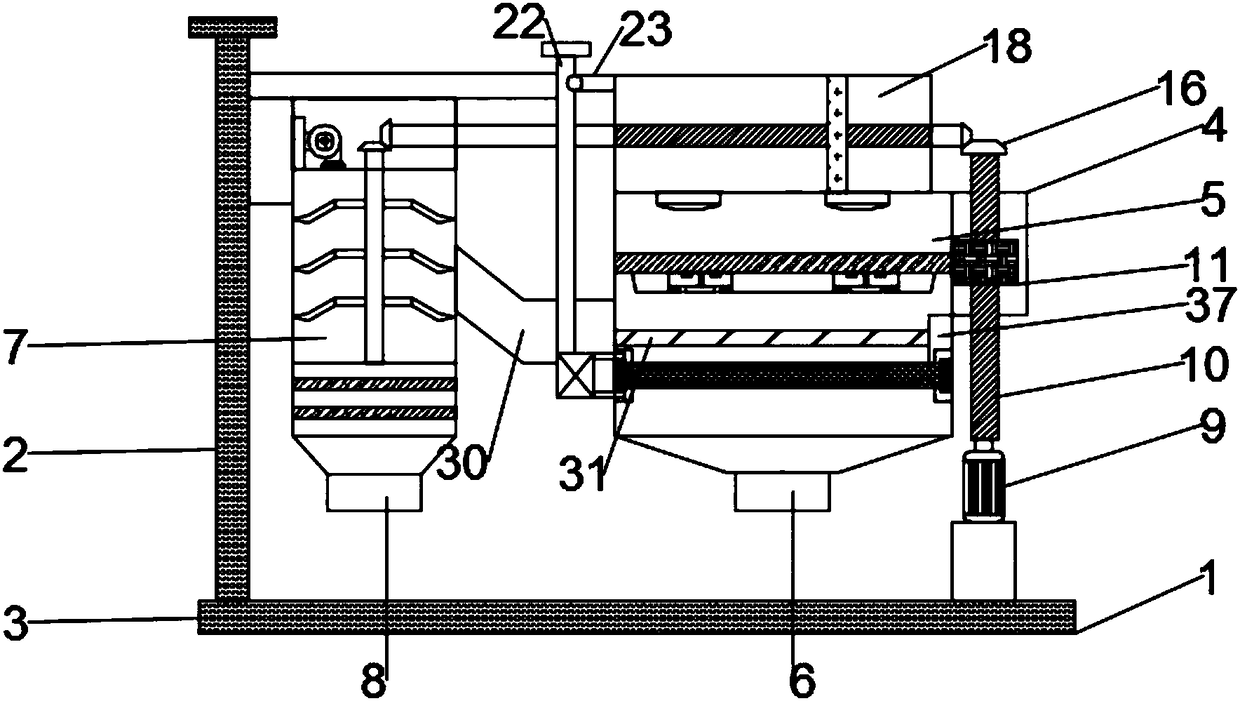

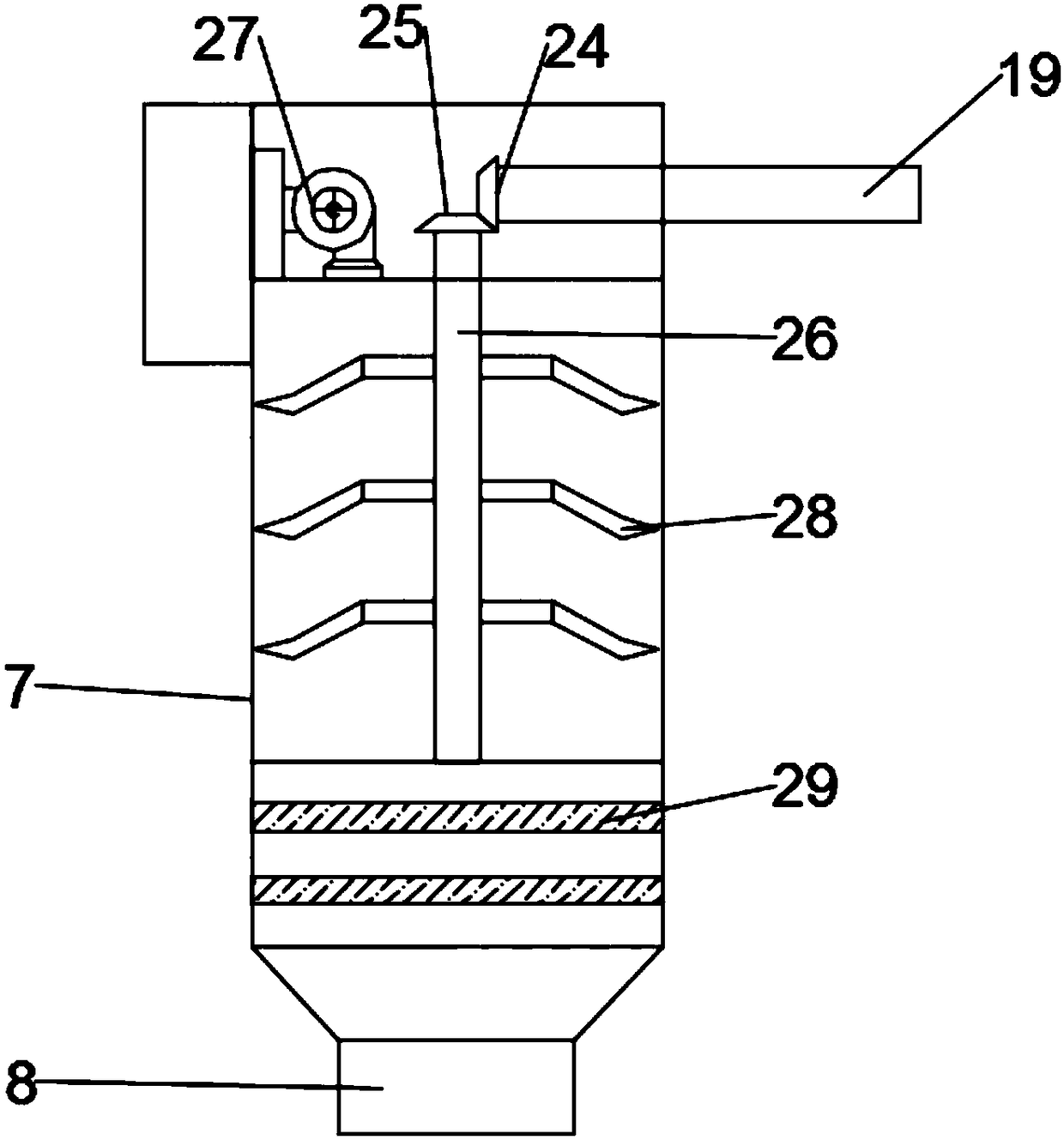

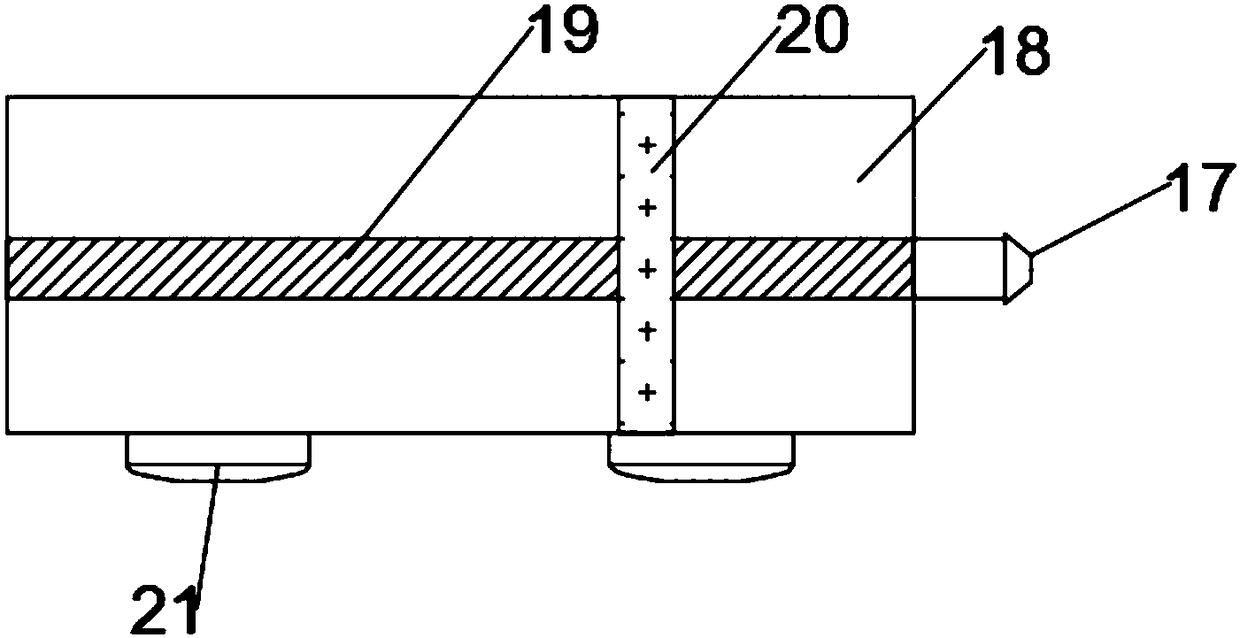

Hazardous waste sludge separation type treatment device

InactiveCN110835224ATo achieve the separation effectEasy to deal with separatelySludge treatmentTreatment involving filtrationSludgeEngineering

The invention relates to the related field of environmental protection, and concretely relates to a hazardous waste sludge separation type treatment device. The device comprises a sludge conveying frame, a sludge treatment box and a sewage treatment box, a conveying cylinder and a water accumulation tank are arranged on the sludge material conveying frame, the water accumulation tank is mounted onthe outer layer of the conveying cylinder in a wrapping manner, a dredge pump joint is mounted at the bottom end of the conveying cylinder, a plurality of water outlet holes are formed in the outer wall of the conveying cylinder, a spiral auger is installed in the conveying cylinder, a discharging end is arranged at the top of the conveying cylinder, a conical structure is arranged at the discharging end, the inner diameter of the cylinder wall of the conical structure is gradually reduced, a discharging port is arranged at the side edge of the top of the discharging end, and a conveying pumpis mounted at the discharging port. The device firstly separates a water liquid from the sludge, and then separately treats the water liquid and the sludge, so that the flammable and combustible risks of the hazardous waste sludge are avoided.

Owner:徐州鸿誉环境科技有限公司

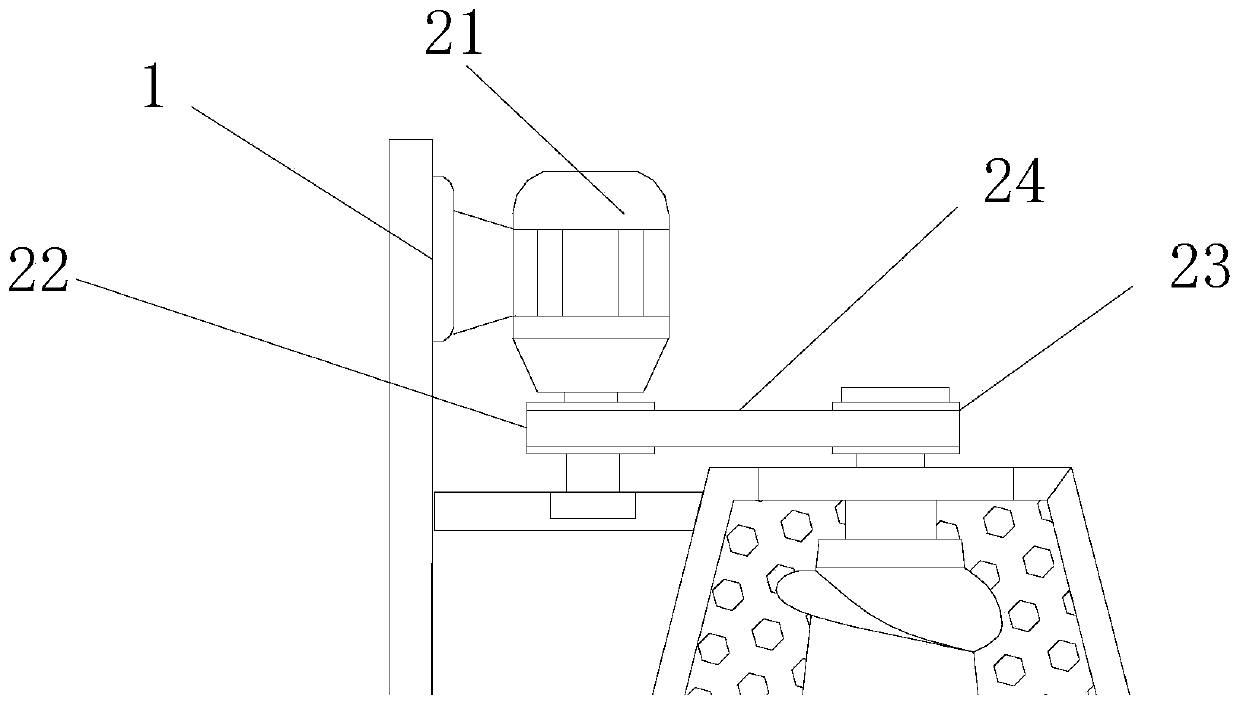

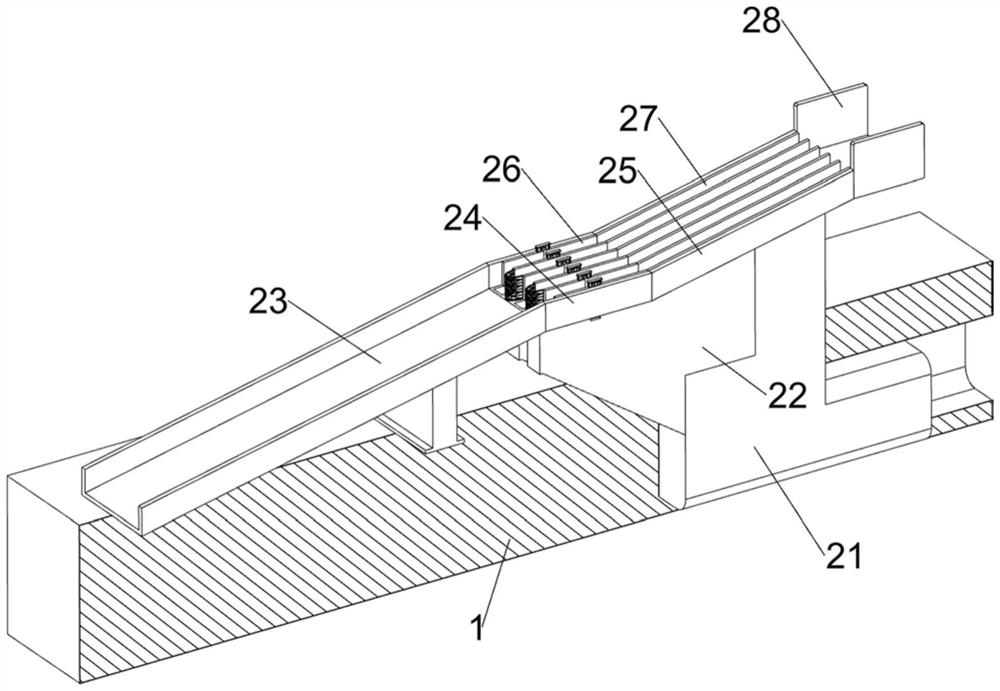

PCB laminated plate counting equipment based on a parallel robot

PendingCN109711524AEasy accessEasy to adjustCounting mechanisms/objectsSortingEngineeringMechanical engineering

The invention discloses PCB lamination counting equipment based on a parallel robot. The device comprises a first electric cabinet and a second electric cabinet, the first electric cabinet is positioned in front of the second electric cabinet; two PCB front-section conveying lines are fixedly installed between the outer surfaces of the upper ends of the two first electric cabinets. a PCB feeding mechanism is fixedly mounted on the outer surface of the front end of the PCB front-section conveying line; a first camera is arranged above the PCB feeding mechanism, a PCB rear-section conveying lineis arranged behind the PCB front-section conveying line, and an NG plate taking mechanism is fixedly installed between the PCB front-section conveying line and the PCB rear-section conveying line. Byarranging a series of structures, a user can conveniently adjust the position of the first camera in the using process of the equipment, so that the material number period of the PCB is obtained, thequalification of the PCB is judged, corresponding subsequent processing is conducted according to the qualification of the PCB, the working efficiency of the equipment is improved, and the using process is optimized.

Owner:广东若贝特设备制造有限公司

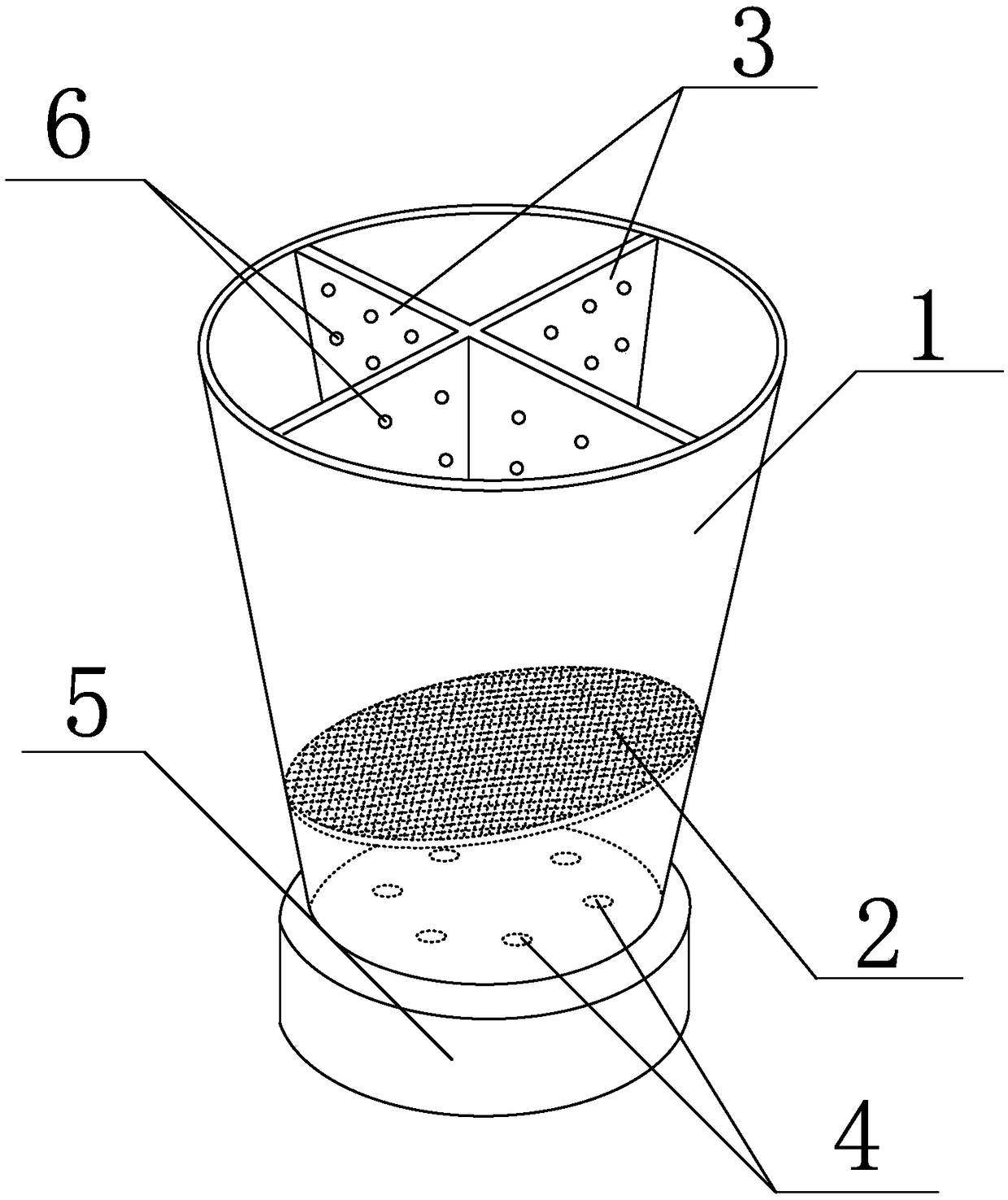

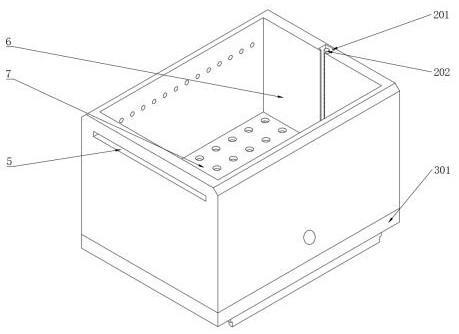

Household dustbin convenient to use

InactiveCN109051446AAvoid situations that are prone to rapid fermentation and deterioration in humid environmentsAvoid odorWaste collection and transferRefuse receptaclesWater leakageSolid structure

The invention discloses a household dustbin convenient to use. The household dustbin convenient to use includes a dustbin body, a filter plate arranged obliquely is arranged on the bottom face of theinner wall of the dustbin body, a garbage cavity is formed in the upper portion of the filter plate, a water collecting cavity is formed in the lower portion of the filter plate, the upper portion ofthe filter plate is provided with two partition plates arranged in a cross way, the partition plates divides the garbage cavity into four cavities, wherein two cavities arranged diagonally are wet garbage cavities, the filter plate on the lower portion of the wet garbage cavities is of a grid-shaped structure, the other two cavities arranged diagonally are dry garbage cavities, the filter plate onthe lower portion of the dry cavities is of a solid structure, the bottom face of the dustbin body is provided with a plurality of water leakage holes, and the lower portion of the dustbin body is provided with a water collecting clearing box. According to the household dustbin convenient to use, moisture can be filtered from wet garbage for storage separately, the condition that some garbage areprone to rapid fermentation and deterioration in a humid environment due to the fact that all garbage are stacked together is avoided, generation of peculiar smell is avoided, and relative cleanliness of the dustbin is maintained.

Owner:蒋祥春

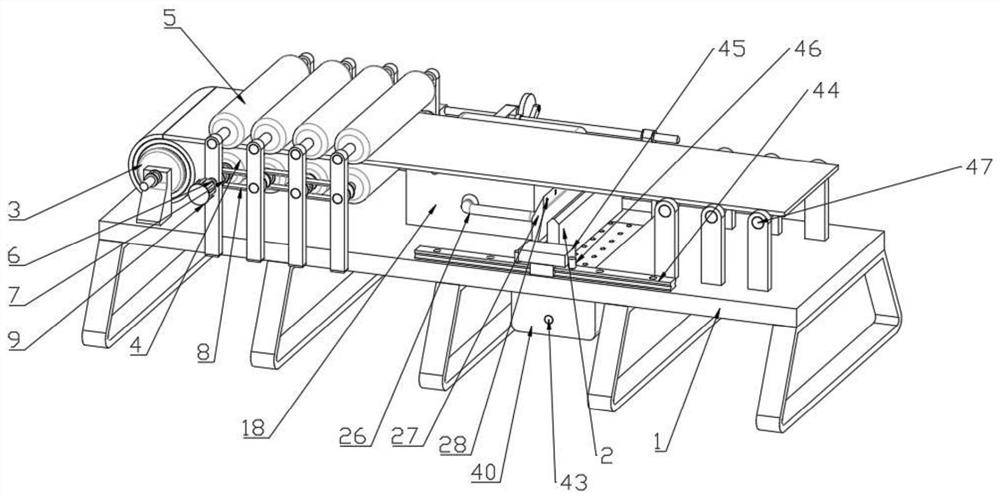

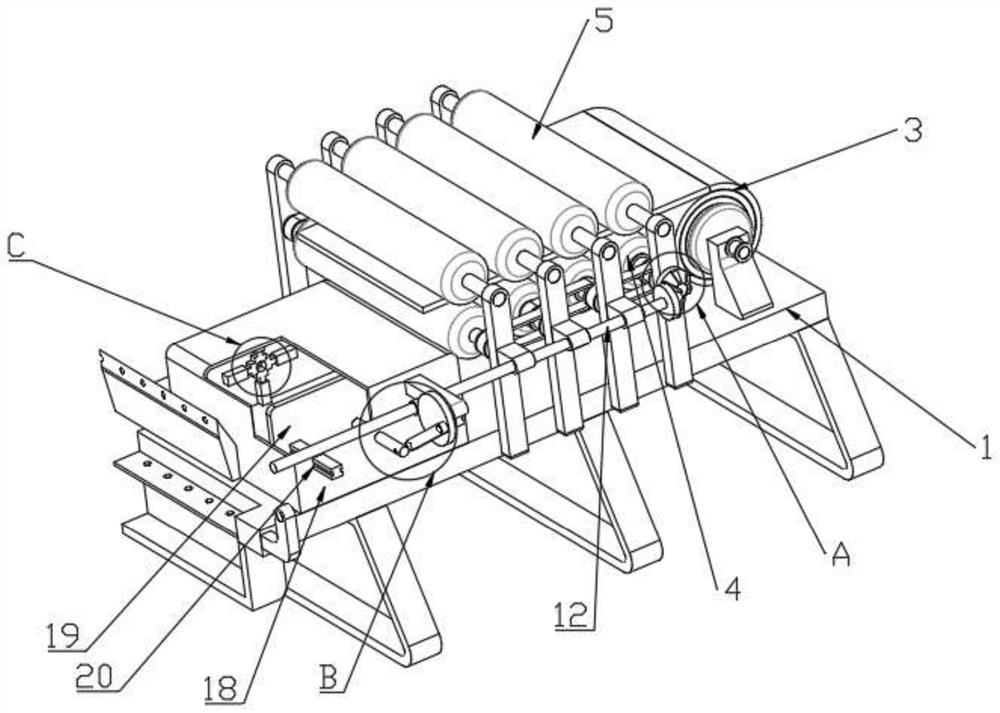

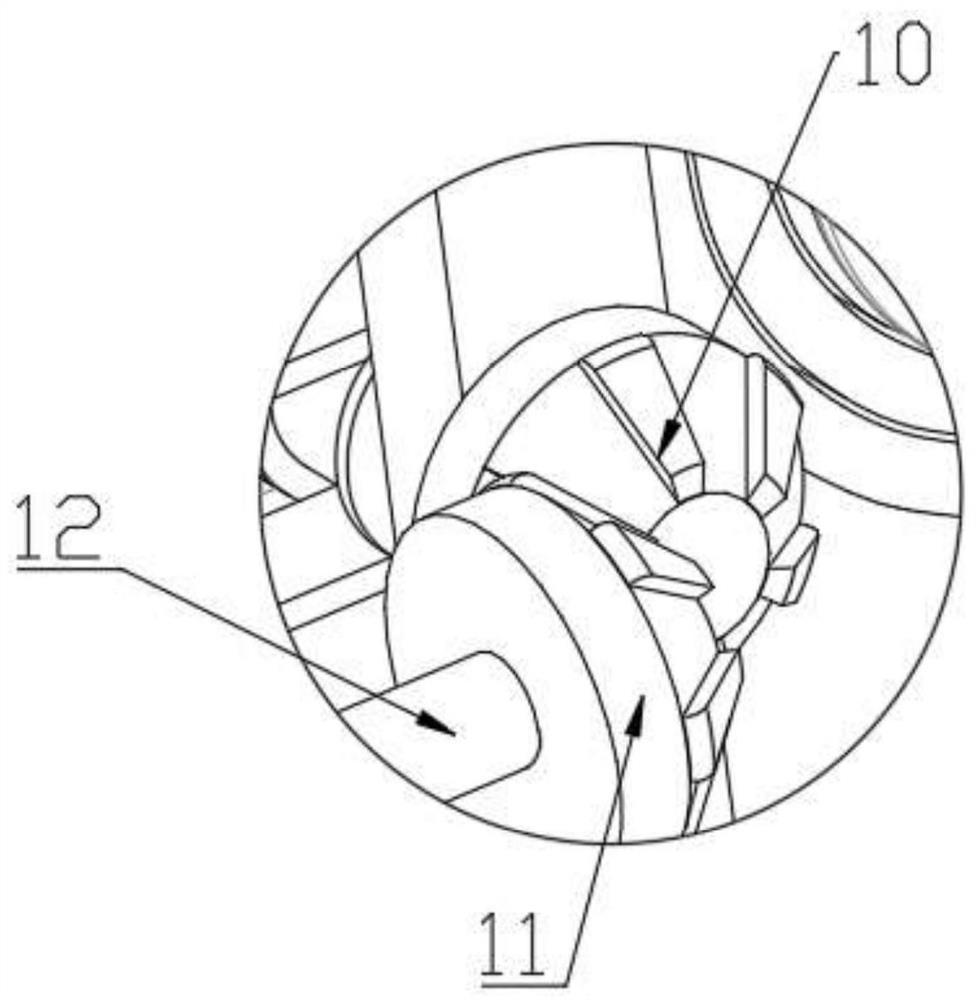

Unreeling machine convenient for cutting for hardware machining

InactiveCN111940809ASimple structureReduce capital investmentShearing machinesMaintainance and safety accessoriesElectric machineryRotational axis

The invention discloses an unreeling machine convenient for cutting for hardware machining. The unreeling machine comprises a workbench and a cutting device; a reeling drum is arranged on the left side of the workbench; a plurality of driving rollers distributed in parallel are arranged on the left side of the upper end of the workbench; a plurality of driven rollers are arranged on the upper sides of the driving rollers; each rotating shaft I penetrates through the inner side of the corresponding driving roller and is fixedly connected with the corresponding driving roller; transmission wheels I are arranged on the outer sides of a plurality of adjacent driving rollers in a sleeving mode; each transmission wheel I is internally provided with a transmission belt I in a clamping manner; andeach motor is installed on one side of the corresponding rotating shaft I. When the unreeling machine disclosed by the invention is used, the motor is used for driving the driving rollers and the rotating shaft I to rotate; each rotating shaft I penetrates through the corresponding transmission belt I; the transmission belts I are used for driving the plurality of driving rollers to move simultaneously; raw materials for hardware machining are straightened in a pressing way through extrusion of the driving rollers and the driven rollers; meanwhile the raw materials can be pulled to move; andthe raw materials drive the reeling drum to rotate to continuously straighten the raw materials wound on the outer side of the reeling drum.

Owner:尹梅存

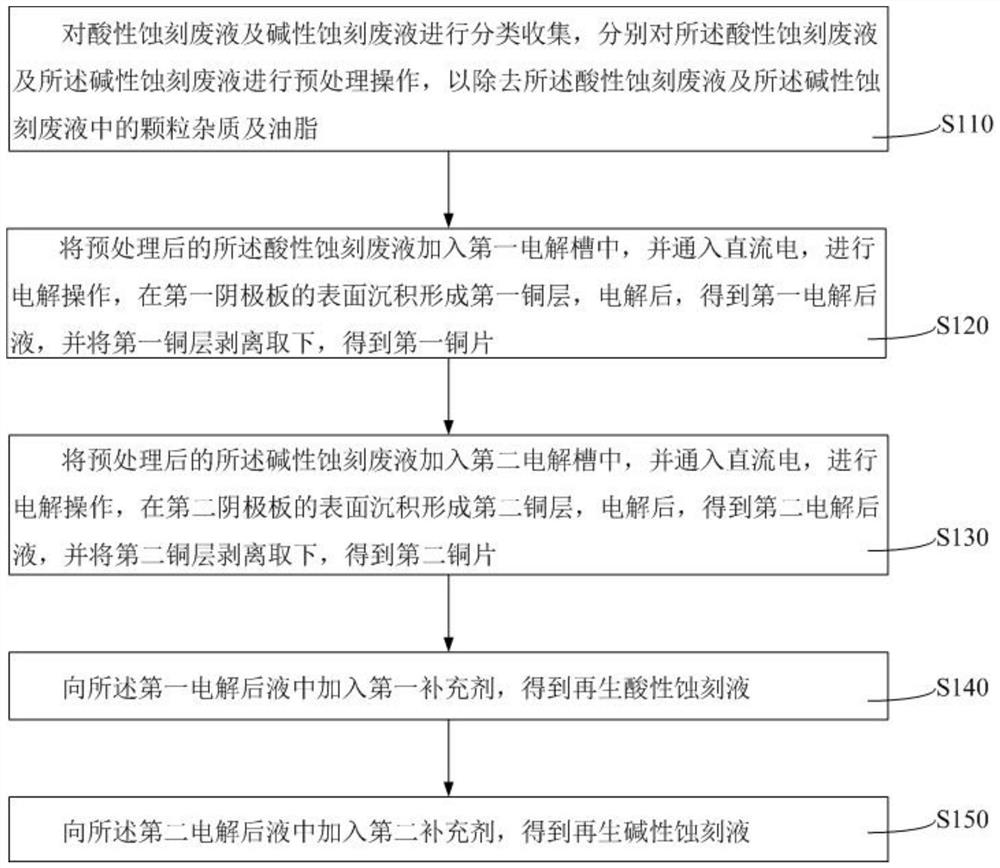

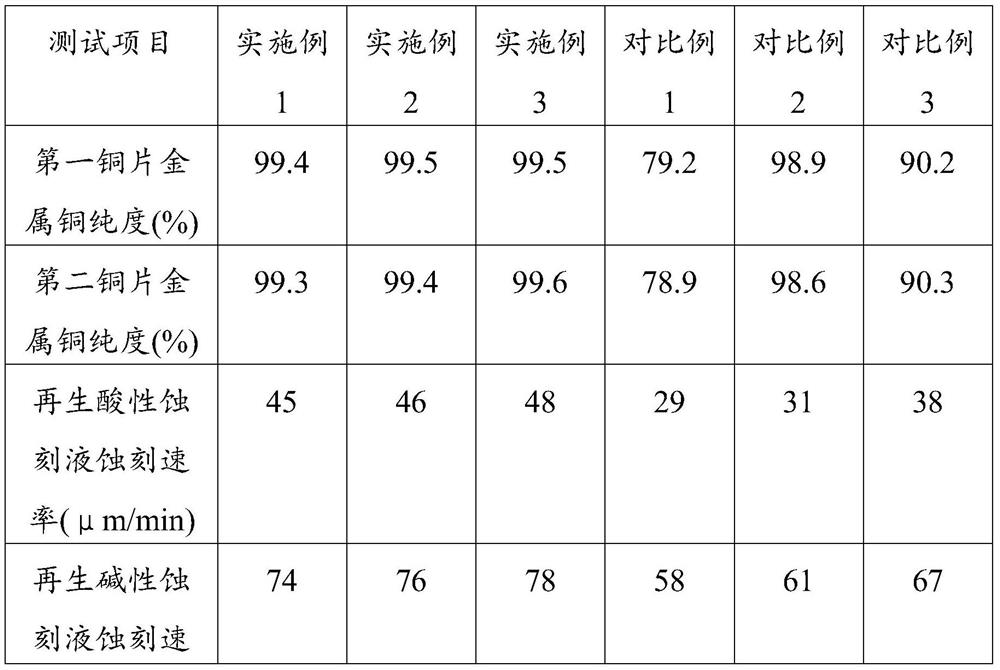

Method for recovering and regenerating copper in waste etching liquid

PendingCN113584487AHigh purityImprove qualityPhotography auxillary processesElectrolysis componentsChemistryElectrolysis operation

The invention relates to a method for recovering and regenerating copper in waste etching liquid. The method comprises the following steps of classifying and collecting acidic waste etching liquid and alkaline waste etching liquid, and correspondingly carrying out pretreatment operation on the acidic waste etching liquid and the alkaline waste etching liquid; adding the pretreated acidic waste etching liquid into a first electrolytic bath, and introducing direct current to carry out electrolysis operation; adding the pretreated alkaline waste etching liquid into a second electrolytic bath, and introducing direct current to carry out electrolysis operation; adding a first supplement into a first electrolyzed solution to obtain a regenerated acidic etching solution; and adding a second supplement into a second electrolyzed liquid to obtain a regenerated alkaline etching liquid. The acidic waste etching liquid and the alkaline waste etching liquid are pretreated, so that normal electrolysis operation is guaranteed, the purity of copper obtained through electrolysis can be greatly improved, the regenerated acidic etching liquid and the regenerated alkaline etching liquid can be obtained correspondingly, recycling of the acidic waste etching liquid and the alkaline waste etching liquid is achieved, the process is simple, and the energy is saved.

Owner:HONGLI SHANTOU ELECTRONICS TECH LTD

Oxide layer removing device for aluminum alloy production

InactiveCN111805387AEasy to cleanEffective classificationGrinding drivesTreatment involving filtrationElectric machineSewage

The invention relates to the technical field of oxide layer removing, in particular to an oxide layer removing device for aluminum alloy production. The oxide layer removing device comprises an oxidelayer removing device body; the oxide layer removing device body comprises a device shell, the surface of the top end of the device shell is connected with a first motor, and the output end of the first motor is connected with a transmission mechanism; the inner wall of the device shell is connected with a conveying roller, the inner wall of the device shell is connected with an electric sliding rod, the surface of the electric sliding rod is connected with a polishing mechanism, and the bottom end of the device shell is internally connected with a sewage purification mechanism; and the innerwall of the top end of the device shell is connected with a liquid injection spraying head. By arranging the polishing mechanism, an oxide layer on the surface of an aluminum alloy plate can be effectively cleared, and the strength of aluminum alloy metal is not damaged; and the device is provided with the sewage purification mechanism so that a cleaning solution after cleaning of an aluminum alloy can be effectively classified, and later treatment is convenient.

Owner:TONGJI UNIV

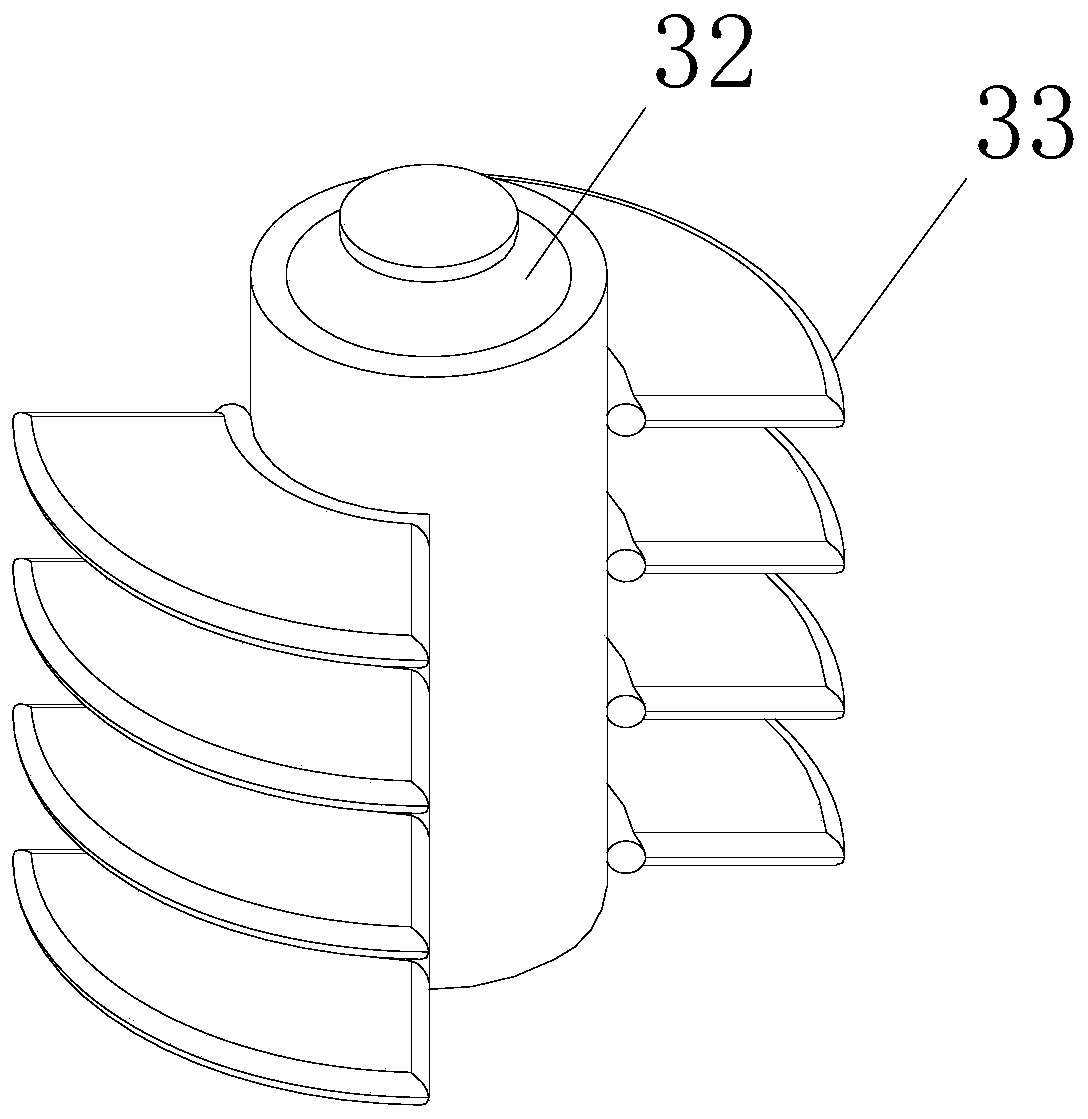

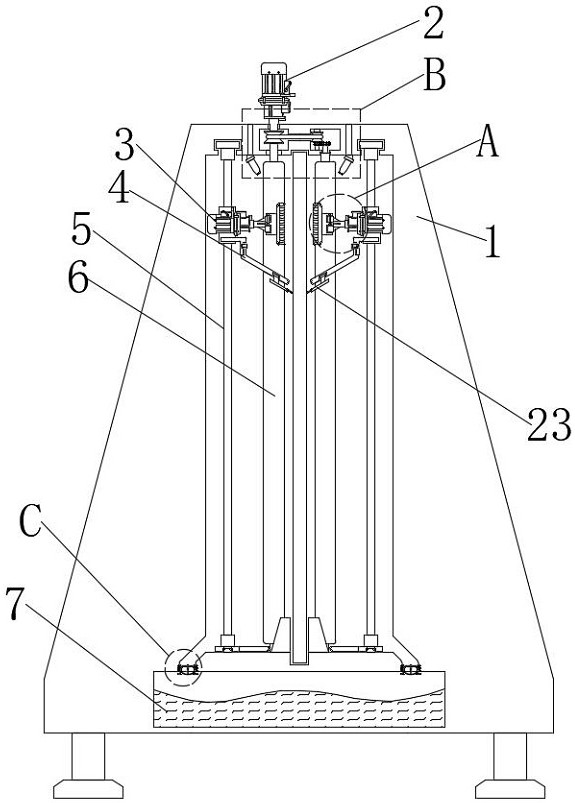

Oil-sludge-sand three-phase separation treatment system and application thereof

ActiveCN104743757AEfficient separationEfficient three-phase centrifugal separationSludge treatmentRefluxEngineering

The invention relates to an oil-sludge-sand three-phase separation treatment system which comprises a heating and stirring kettle for heating and stirring materials and a three-phase separation machine communicated with the heating and stirring kettle. According to the system, the rotary stirring of the materials is enhanced by a centrifugal barrel and a stirring rotating shaft barrel, which rotate in opposite directions, and meanwhile, the materials are subjected to three-phase separation under a centrifugal force generated by high-speed rotation of the centrifugal barrel; since a screw blade is mutually attached to the inner wall of the centrifugal barrel, a sand phase is conveyed to a sand phase discharge opening as the screw blade rotates, and an oil phase and a water phase are closely attached to the screw blade under the action of the centrifugal force and finally flow back to the large-diameter end of the centrifugal barrel along liquid-phase reflux holes in the screw blade; and according to the stratification condition of the water phase and the oil phase on the wall of the centrifugal barrel, namely that the water phase is closely attached to the inner wall of the centrifugal barrel under the action of the centrifugal force, followed by the oil phase, a water phase outlet and an oil phase outlet are concentrically formed in the large-diameter end of the centrifugal barrel respectively so as to lead the water phase and the oil phase out respectively.

Owner:威海恒荣环保科技有限公司

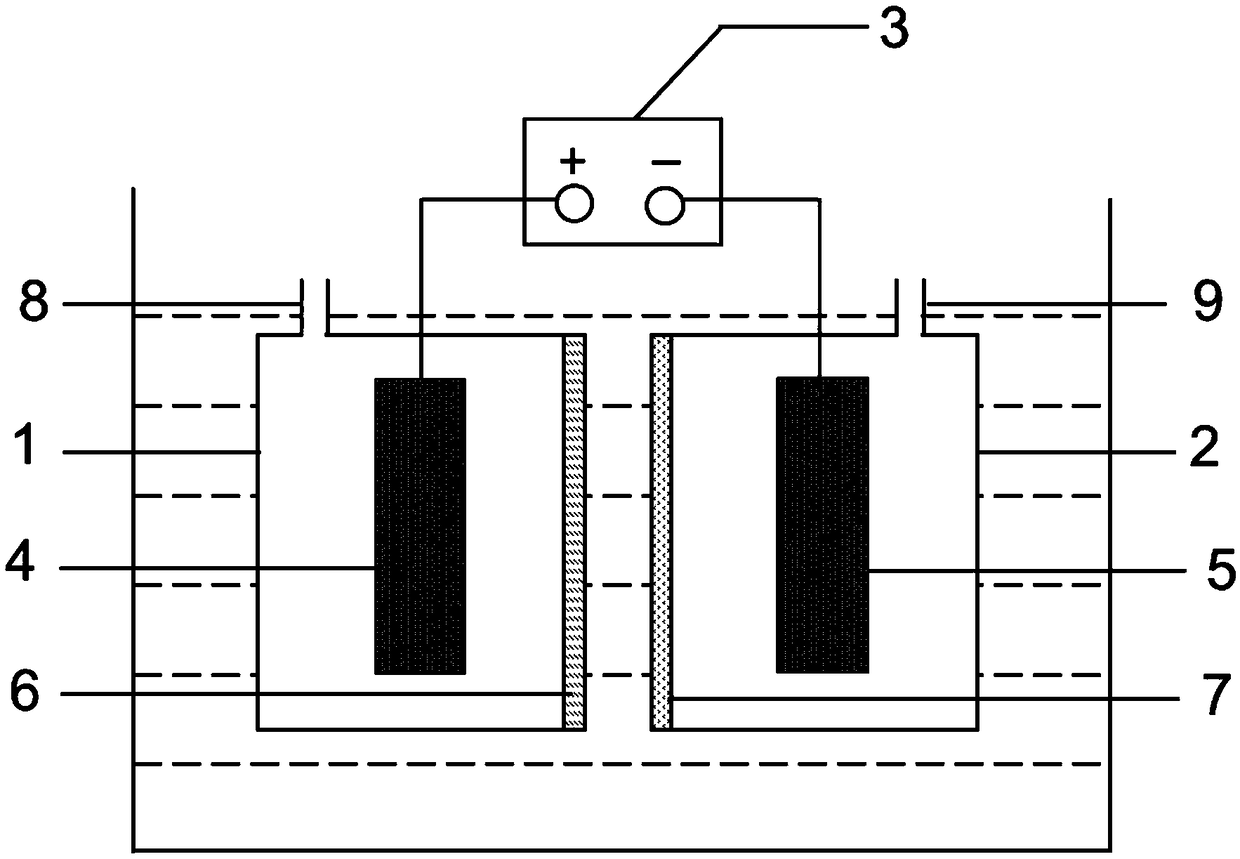

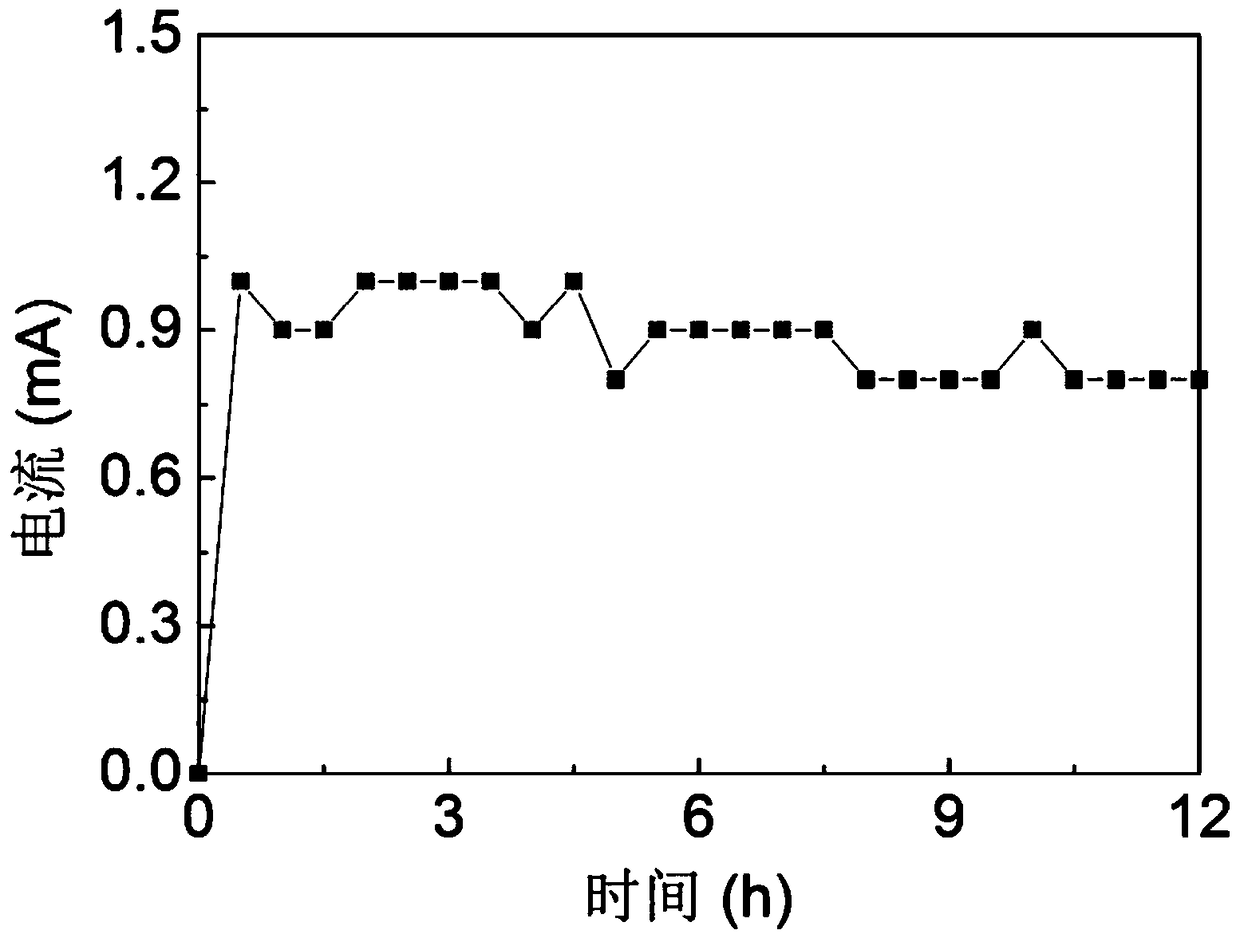

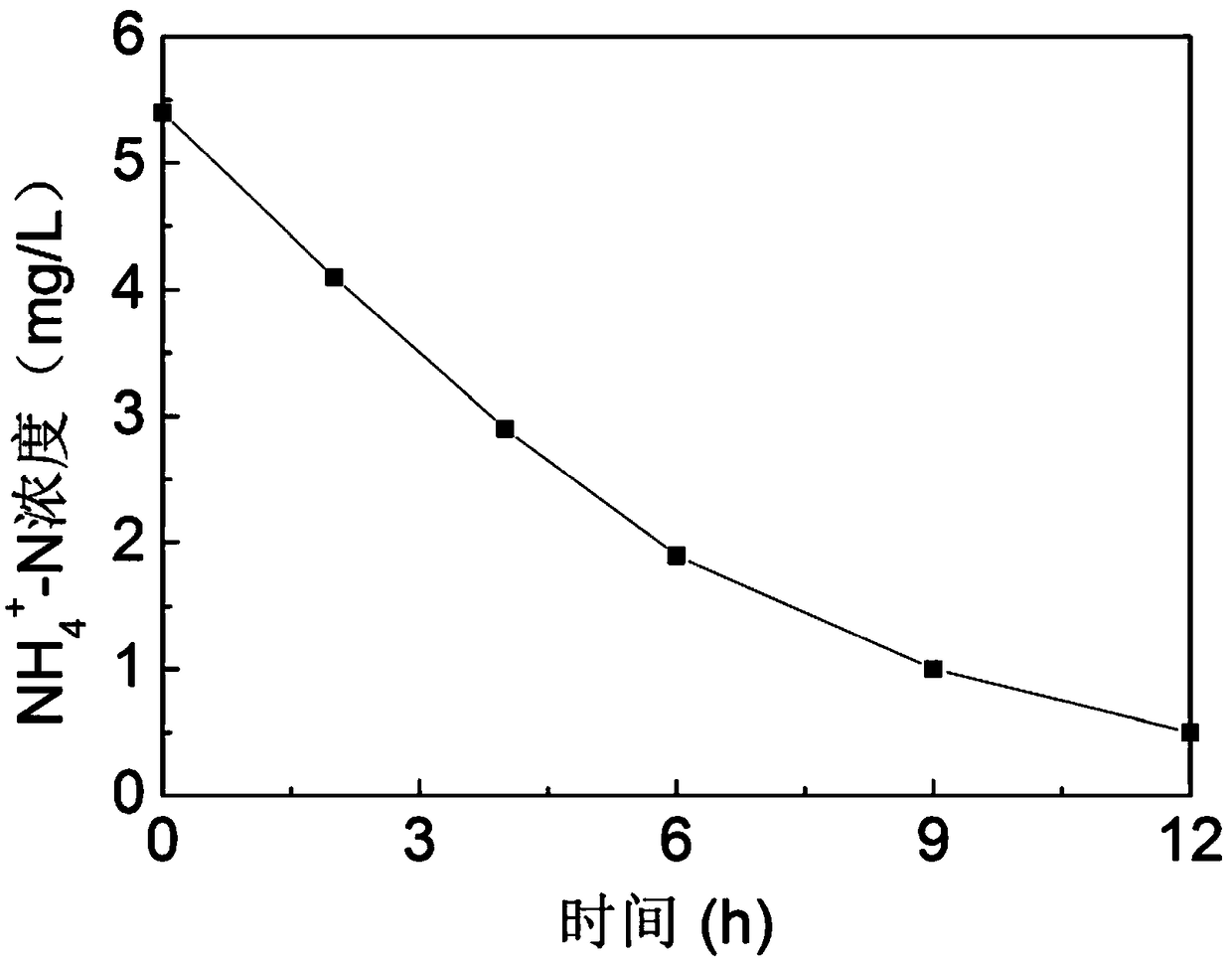

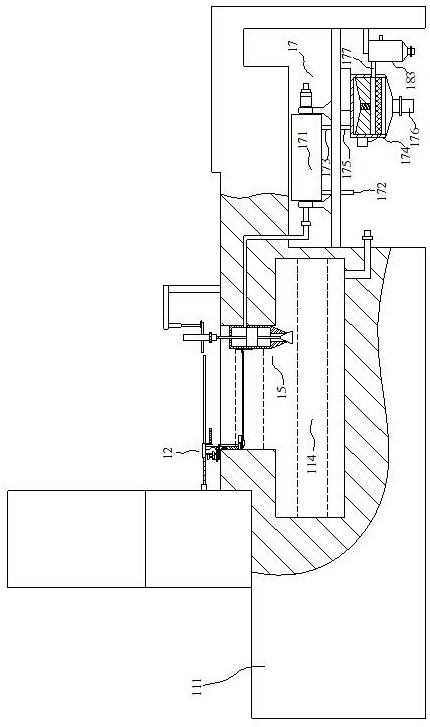

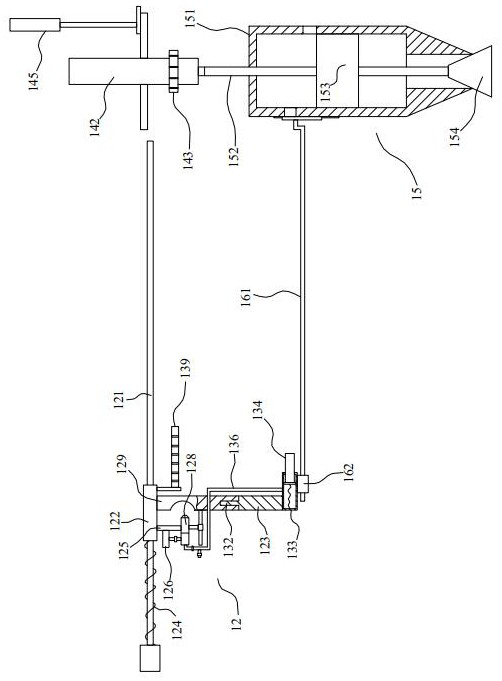

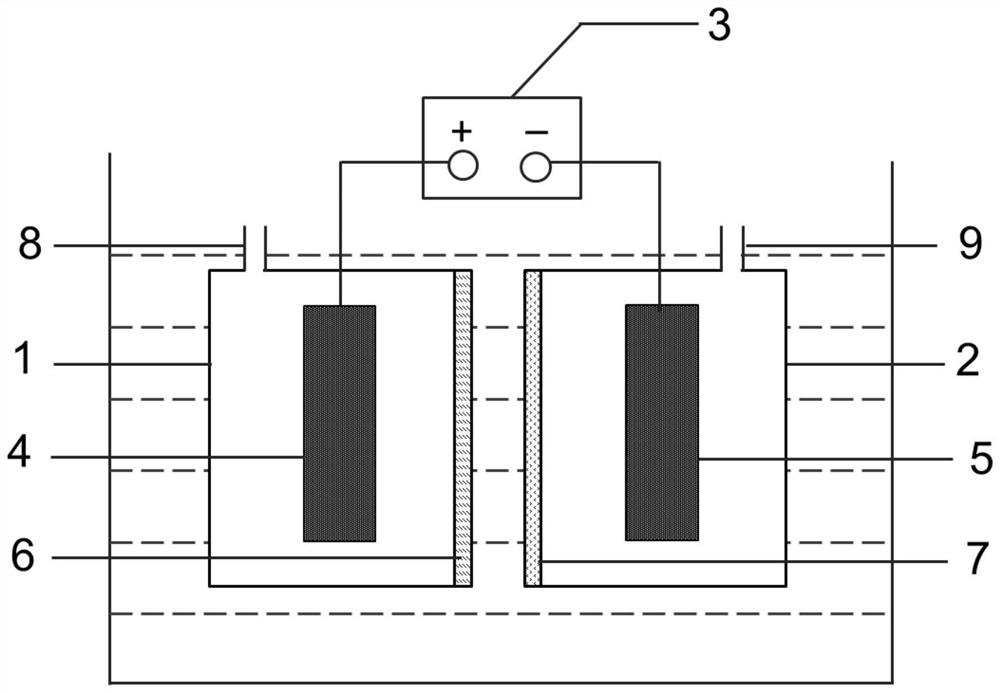

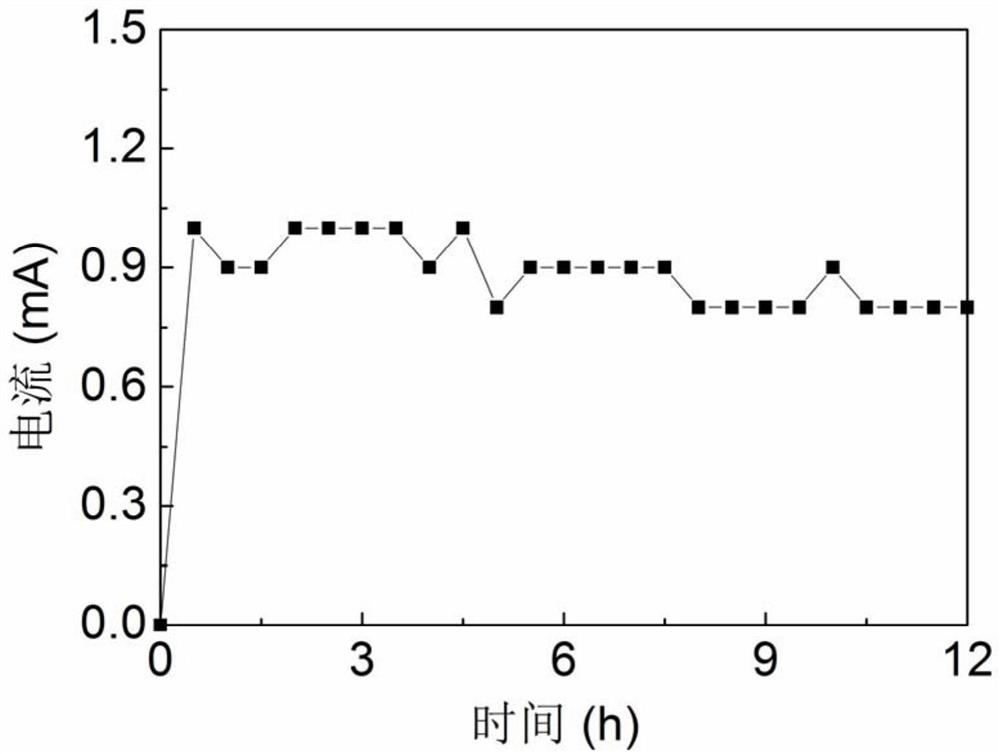

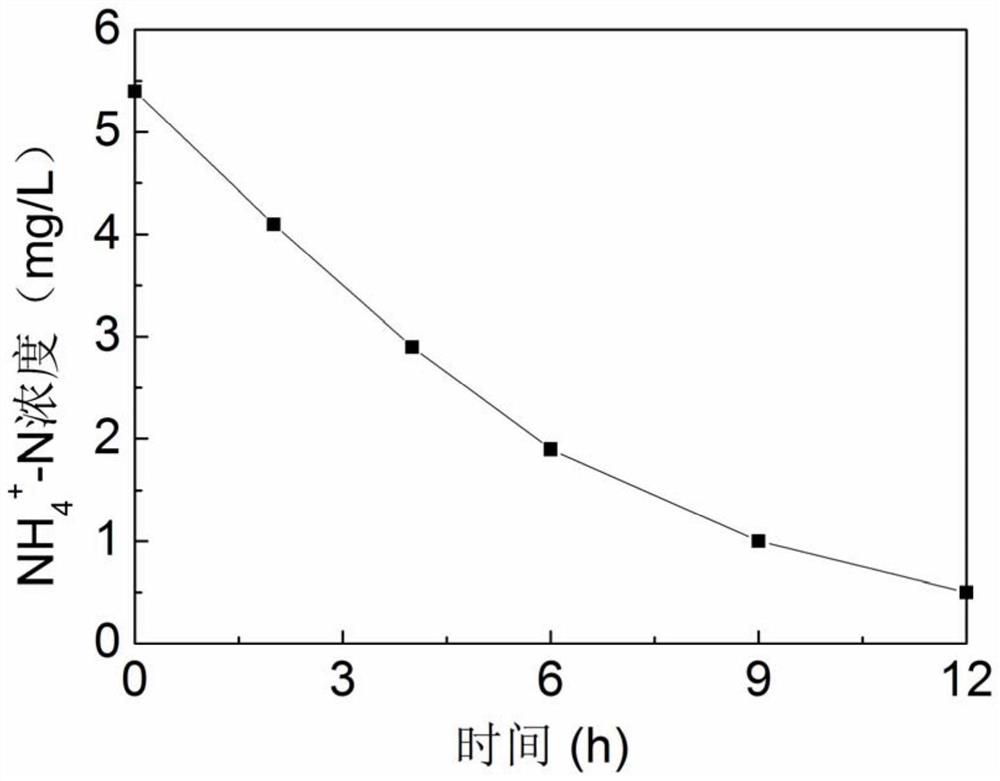

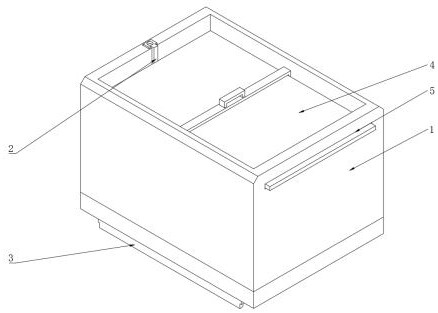

Immersed electrochemical in-situ nutrient salt enrichment device and method for removing nutrient salt from surface water

ActiveCN108751359AEasy to handleWon't interfereDispersed particle separationWater/sewage treatmentNutrientIon-exchange membranes

The invention discloses an immersed electrochemical in-situ nutrient salt enrichment device and a method for removing nutrient salt from surface water and relates to a nutrient salt enrichment deviceand method with an aim to solve the problem of poor effect of chemical and biological treatment of nutrient salt. The immersed electrochemical in-situ nutrient salt enrichment device is formed by an anode chamber, a cathode chamber, a power supply, an anode, a cathode, an anion exchange membrane and a cathode exchange membrane; one side wall of the anode chamber and the cathode chamber is open andcovered with the anion exchange membrane and the cathode exchange membrane respectively; the cathode exchange membrane and the anion exchange membrane are oppositely arranged. The anode chamber and the cathode chamber are immersed in nutrient salt contaminated water to apply voltage to collect concentrated phosphate and ammonium slat solutions obtained in the anode chamber and the cathode chamber, and after the concentrated phosphate and the ammonium slat solution are mixed, magnesium chloride is added and pH is adjusted to generate struvite, and the nutrient salt is finally removed; the nutrient salt in the contaminated water can be enriched in situ, the removal rate of the ammonia nitrogen reaches more than 90%, and the removal rate of the phosphate reaches more than 89%; the immersed electrochemical in-situ nutrient salt enrichment device and the method are suitable for removing the nutrient salt from the surface water.

Owner:HARBIN INST OF TECH

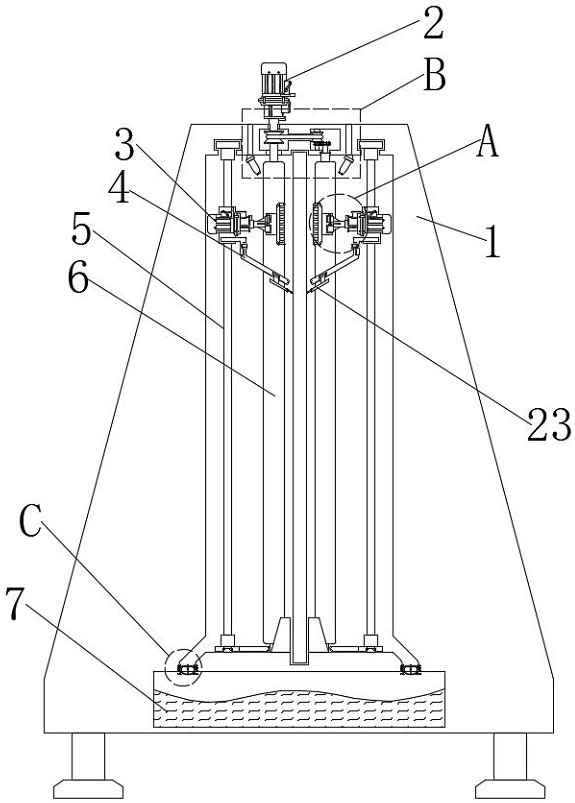

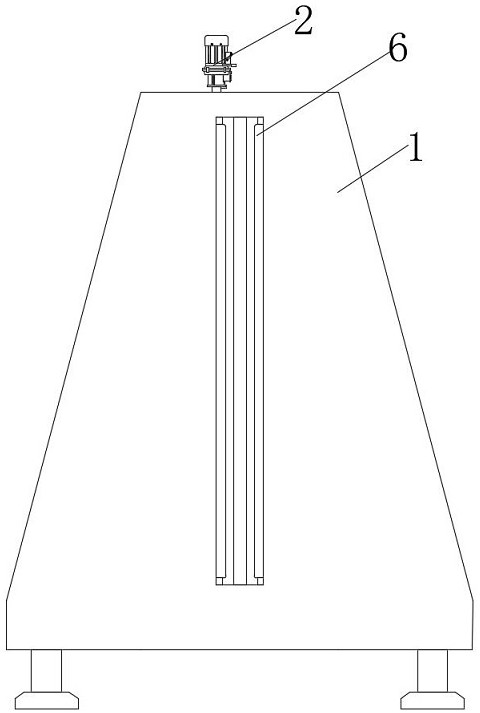

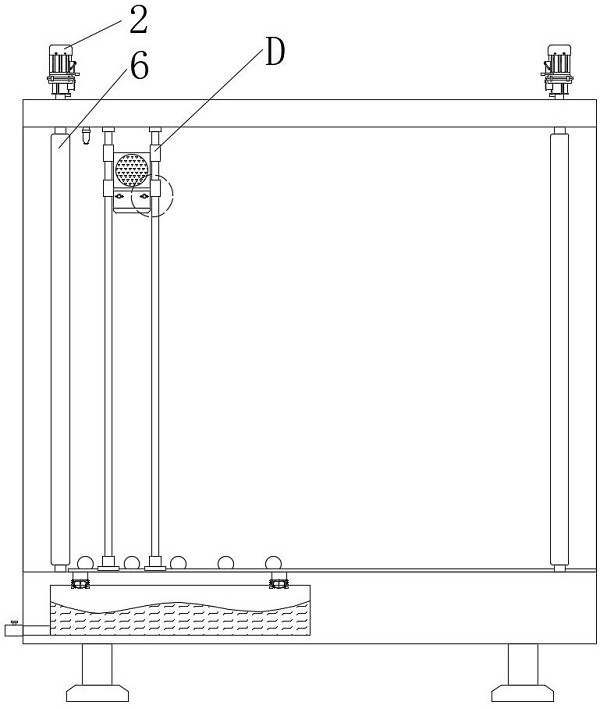

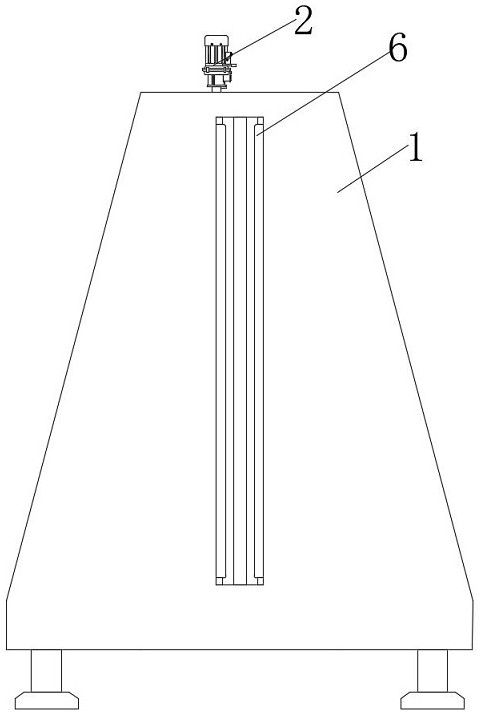

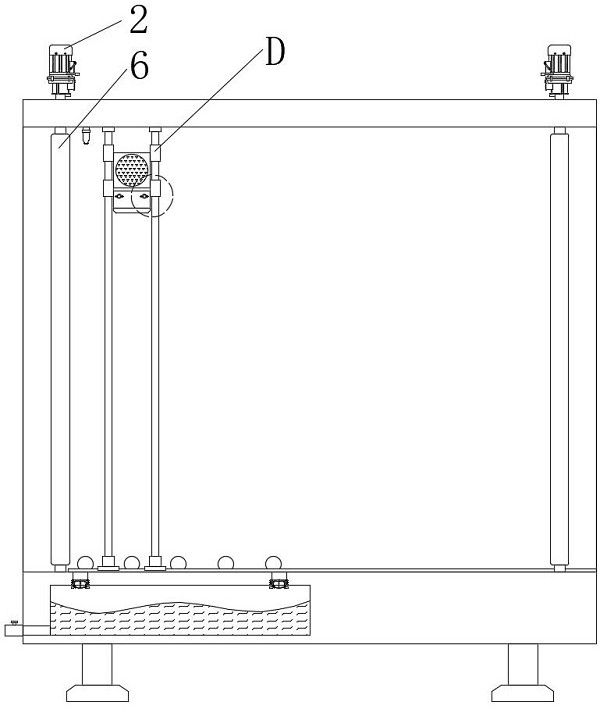

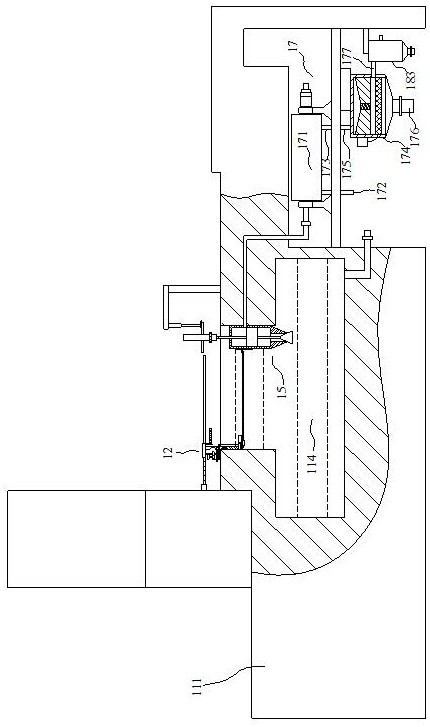

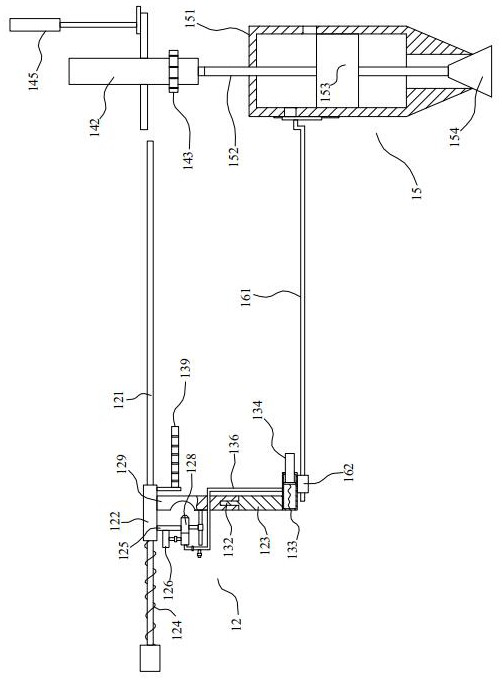

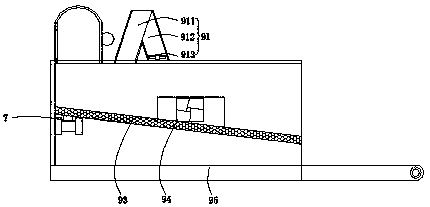

Floating oil recovery system of emulsion for aluminum wire rod hot rolling

ActiveCN114085702ASkimming for convenienceEasy to deal with separatelyLubricant compositionPistonEmulsion

The invention provides a floating oil recovery system of an emulsion for aluminum wire rod hot rolling, and relates to the technical field of electrolytic aluminum production. The floating oil recovery system for the emulsion for aluminum wire rod hot rolling mainly comprises a machine body, an oil skimming mechanism, an oil suction mechanism and a demulsification mechanism. An oil receiving groove is formed in the machine body. The oil skimming mechanism comprises a first guide rod, a first sliding sleeve and an oil driving plate. The oil suction mechanism comprises a suction floating block, a square rod, a piston and a plug. An oil inlet is formed in the left side of the suction floating block, an oil outlet is formed in the right side of the suction floating block, a through hole is formed in the lower portion of the suction floating block, and a valve assembly is arranged at the oil inlet. The plug is matched with the through hole and is fixed at the lower end of the square rod. The demulsification mechanism comprises a horizontal spiral centrifugal machine communicated with the oil outlet, and the floating oil entering the oil inlet flows into the horizontal spiral centrifugal machine from the oil outlet to separate a solid phase from a liquid phase so as to facilitate respective treatment.

Owner:阿坝铝厂

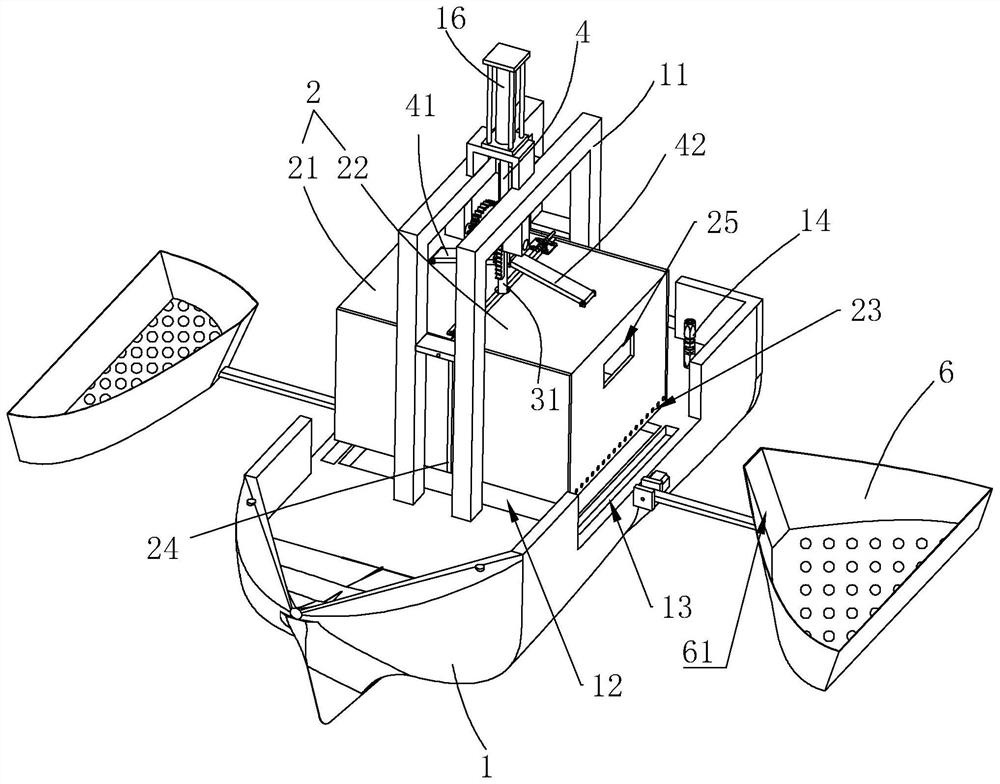

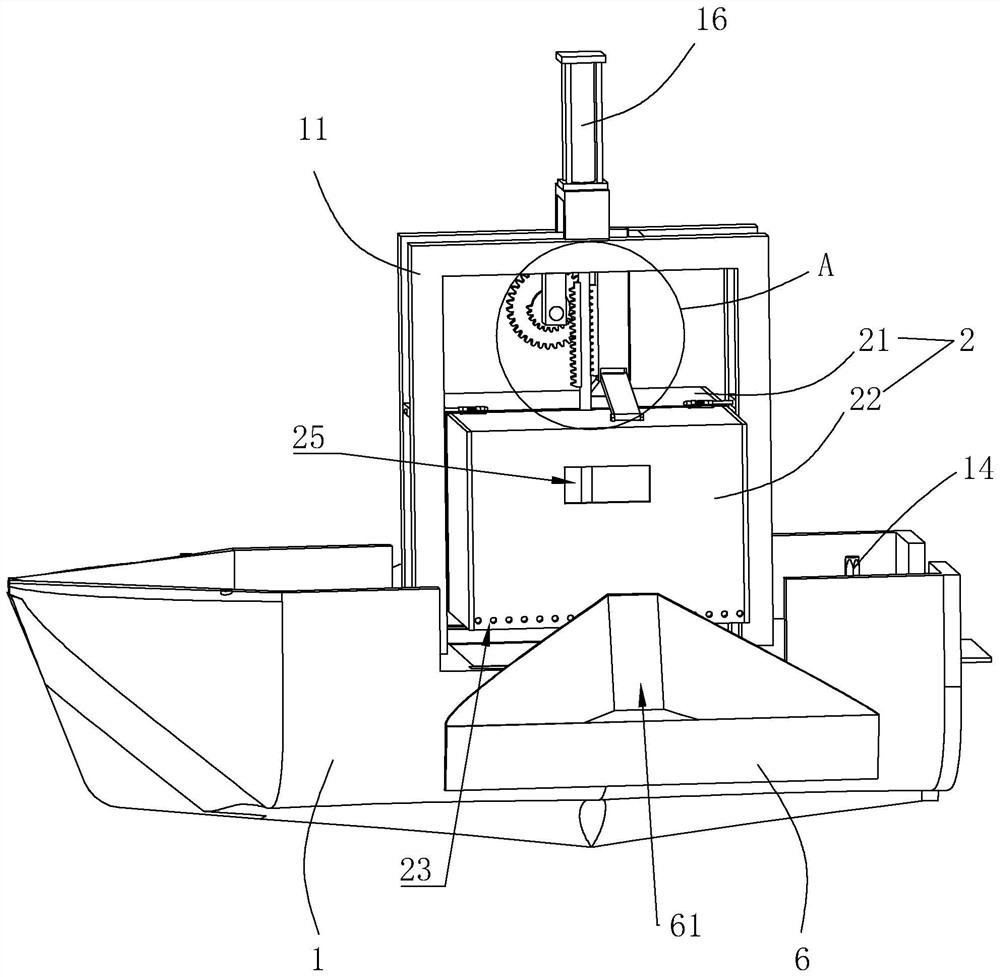

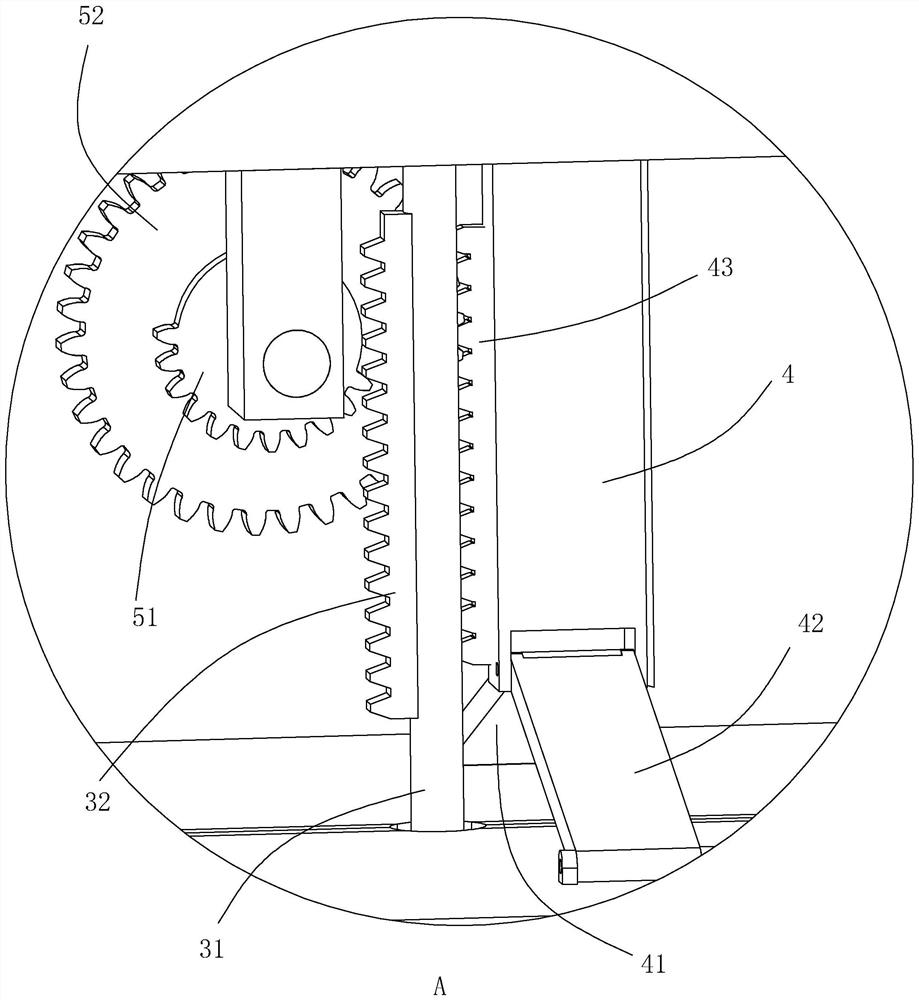

A river surface garbage disposal device

ActiveCN110512578BReduce usageConvenient supplementWater cleaningPressesStructural engineeringSewage

The invention relates to a river surface garbage disposal device, comprising a hull, a frame is arranged on the hull, the frame is hinged with a left box body and a right box body, the left box body and the right box body are penetrated with a drain hole, and the left box body and the right box body are provided with drain holes. The bodies are connected to each other and form a squeeze box, the frame is slidably connected with a squeeze plate through the driving part, and the squeeze plate slides up and down in the squeeze box; the frame slides vertically above the hinge point of the left box body and the right box body. The support rod, the upper end surfaces of the left box body and the right box body are respectively hinged with a first connecting rod and a second connecting rod, and the other ends of the first connecting rod and the second connecting rod are both hinged with the support rod; between the support rod and the extrusion plate An intermittent linkage mechanism is provided, and the intermittent linkage mechanism drives the support rod to reciprocate during the movement of the extrusion plate. Through the above arrangement, when the surface garbage is accumulated in the squeeze box after being salvaged, the squeeze plate moves downward to squeeze the garbage to drain water, so that the sewage flows out from the drain hole, so that the solid and liquid are separated, so that the hull can carry more Rubbish.

Owner:GUANGZHOU NANCHAO ENVIRONMENTAL SANITATION SERVICE

An intelligent, energy-saving and environment-friendly organic waste treatment device

ActiveCN110802099BSave resourcesEasy to crushSolid waste disposalTransportation and packagingGear wheelElectric machinery

An intelligent, energy-saving and environment-friendly organic waste treatment device, comprising a cylinder body, a rectangular box is installed on the inner wall of the upper end of the cylinder, a fifth through hole is opened on the top of the rectangular box, a feeding funnel is installed on the top of the rectangular box, and the inner walls on the left and right sides of the rectangular box are Horizontal hydraulic telescopic rods are all installed, the first piston block is installed on the left side of the rectangular box, the second piston block is fixedly connected to the right hydraulic telescopic rod, several crushing blades are fixedly installed on the outer wall of the upper end of the rotating shaft, and the first oblique For the gear, the output shaft outer end of the motor is fitted with the second helical gear, and the first helical gear and the second helical gear are installed in cooperation. The present invention can realize a series of automatic pulverization and drying treatment of organic waste by adding organic waste into the funnel, which reduces labor and saves power sources, makes the structure of the present invention as simple as possible, easy to maintain, and the processed organic waste It facilitates the subsequent incineration treatment, so that the organic waste can be fully burned, thereby protecting the ecological environment from being damaged.

Owner:浙江正浩智能制造有限公司

An oxide layer removal device for aluminum alloy production

InactiveCN111805387BEasy to cleanEffective classificationGrinding drivesTreatment involving filtrationElectric machinerySewage

The invention relates to the technical field of oxide layer removal, in particular to an oxide layer removal device for aluminum alloy production, which includes a main body of the oxide layer removal device, the main body of the oxide layer removal device includes a device shell, and the top surface of the device shell is connected with a second A motor, and the output end of the first motor is connected with a transmission mechanism, the inner wall of the device housing is connected with a conveying roller, the inner wall of the device housing is connected with an electric slide bar, and the surface of the electric slide bar is connected with the polishing mechanism. The bottom end of the device shell is connected with a sewage purification mechanism, and the top inner wall of the device shell is connected with a liquid injection nozzle. The invention can effectively clean the oxide layer on the surface of the aluminum alloy plate by setting the polishing mechanism without damaging the strength of the aluminum alloy itself, and the device can effectively clean the cleaning liquid after cleaning the aluminum alloy by setting the sewage purification mechanism Classify to facilitate subsequent processing.

Owner:TONGJI UNIV

Oil recovery system of emulsion for hot rolling of aluminum wire rod

ActiveCN114085702BSkimming for convenienceEasy to deal with separatelyLubricant compositionWire rodThermodynamics

The invention provides a floating oil recovery system of emulsion for hot rolling of aluminum wire rods, and relates to the technical field of electrolytic aluminum production. The slick oil recovery system for the emulsion for hot rolling of aluminum wire rods includes a slick oil recovery system for the emulsion for hot rolling of aluminum wire rods, which may mainly include: a body, an oil skimming mechanism, an oil absorption mechanism and a demulsification mechanism. There is an oil tank on the fuselage. The oil skimming mechanism includes a first guide rod, a first sliding sleeve and an oil catching plate. The oil suction mechanism includes suction float, square rod, piston and plug. The left side of the suction float is provided with an oil inlet, the right side is provided with an oil outlet, the lower part of the suction float is provided with a through hole, and the oil inlet is provided with a valve assembly. The plug matches the through hole and is fixed to the lower end of the square rod. The demulsification mechanism includes a horizontal screw centrifuge connected with the oil outlet, and the floating oil entering the oil inlet flows into the horizontal screw centrifuge from the oil outlet to separate the solid phase and the liquid phase, so as to be processed separately.

Owner:阿坝铝厂

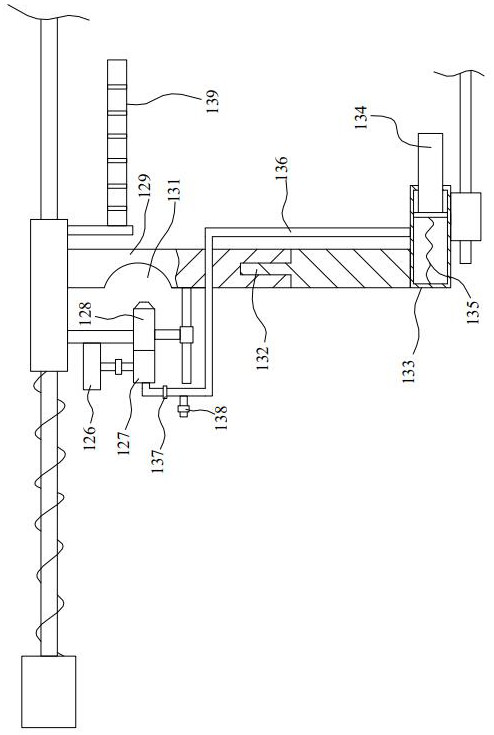

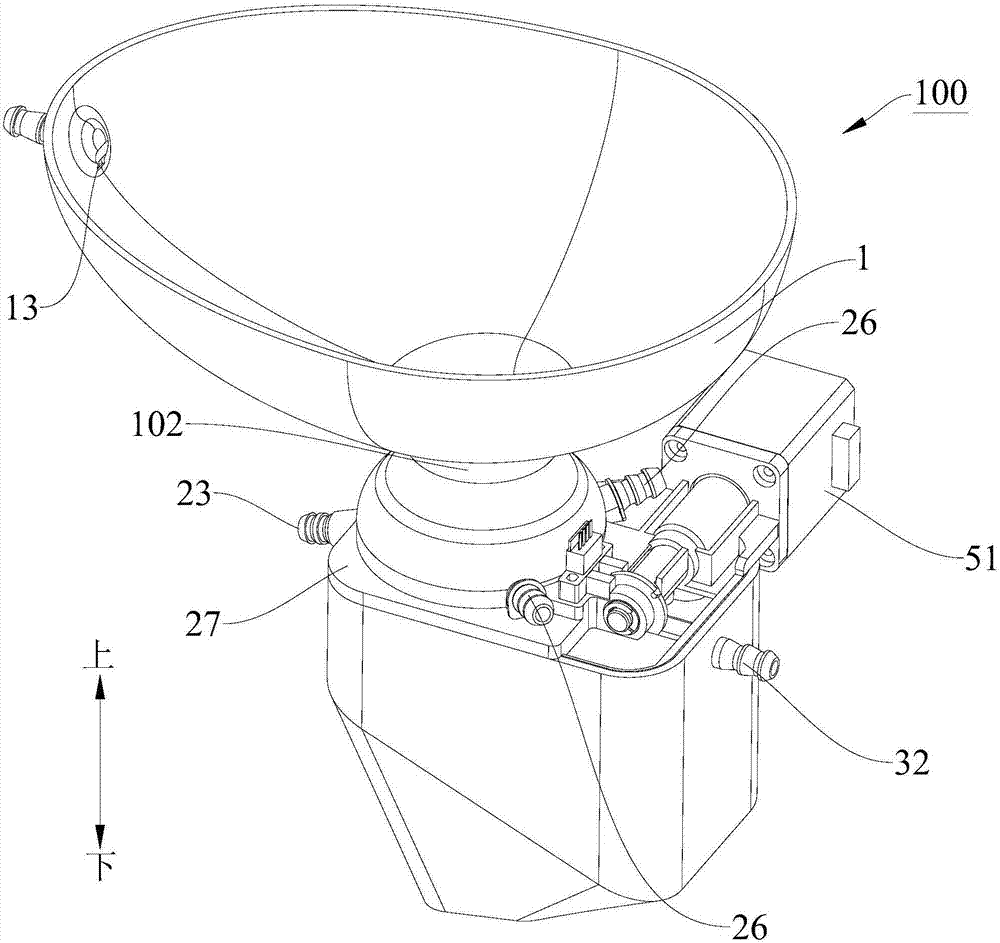

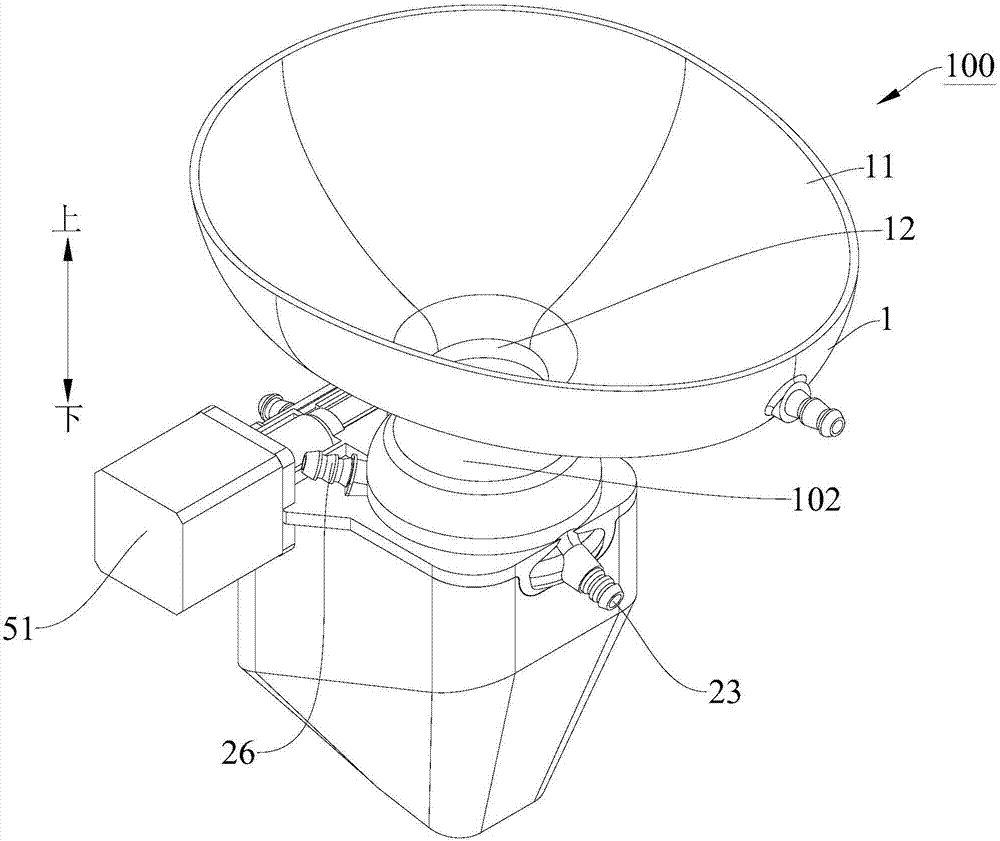

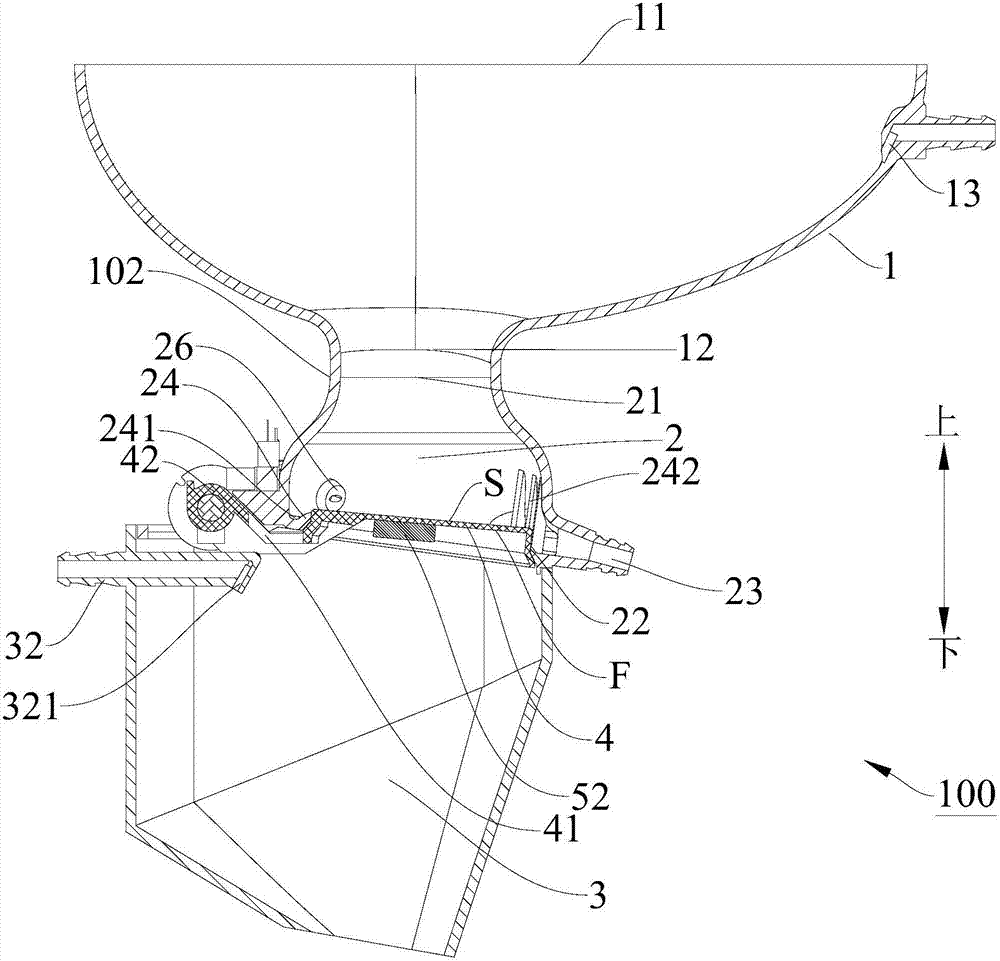

Excreta solid-liquid separation device

InactiveCN105833573BReduce pollutionEasy to deal with separatelySettling tanks feed/dischargeSedimentation settling tanksAnimal fecesEngineering

The invention discloses an excrement solid-liquid separation device which comprises a separation cavity, a solid cavity and a baffle. A solid outlet and a liquid outlet which are separated are formed in the bottom of the separation cavity. The solid cavity is located below the separation cavity. The solid cavity is communicated with the solid outlet. The baffle is movably arranged at the solid outlet to open or close the solid outlet. When excrement is discharged into the separation cavity, the baffle closes the solid outlet. According to the excrement solid-liquid separation device, liquid and solid in excrement is sequentially discharged into the separation cavity through the baffle; the excrement solid-liquid separation device is low in energy consumption, simple and reasonable in layout, capable of reducing environment pollution, beneficial to sequential independent treatment of urine and feces and capable of lowering the consumption of water for treatment.

Owner:GUANGDONG MIDEA WHITE HOME APPLIANCE TECH INNOVATION CENT CO LTD +1

Submerged electrochemical in-situ nutrient enrichment device and method for removing nutrient salt from surface water

ActiveCN108751359BEasy to handleWon't interfereDispersed particle separationWater/sewage treatmentPhosphateNutrition

Owner:HARBIN INST OF TECH

Recyclable self-propelled marine product logistics box

ActiveCN114751072AReduce freshnessQuick take outPisciculture and aquariaRigid containersAgricultural scienceLogistics management

The invention provides a self-propelled marine product logistics box capable of being recycled, and relates to the technical field of logistics boxes, the self-propelled marine product logistics box comprises a box body, a storage groove is formed in the box body, a storage assembly used for rapidly storing and taking materials is fixedly installed on one side of the inner wall of the storage groove, and a walking assembly used for assisting walking is fixedly installed at the bottom of the box body; a water storage tank is formed in the bottom of the storage tank, a filter plate is arranged above the water storage tank, a transmission through hole is formed in one side of the interior of the box body, an expansion cavity is integrally formed in the upper end of the transmission through hole, and a water pump is fixedly installed in the expansion cavity. The carrying strength of workers to the box body is reduced, the box body can be rapidly transferred only by placing the box body on the ground, and in order to avoid the situation that the box body cannot be stacked and stored due to the fact that the walking function is added, walking pulleys can be automatically adjusted through the walking assembly, so that an operator can switch the walking pulleys according to the current environment.

Owner:WEIHAI OCEAN VOCATIONAL COLLEGE

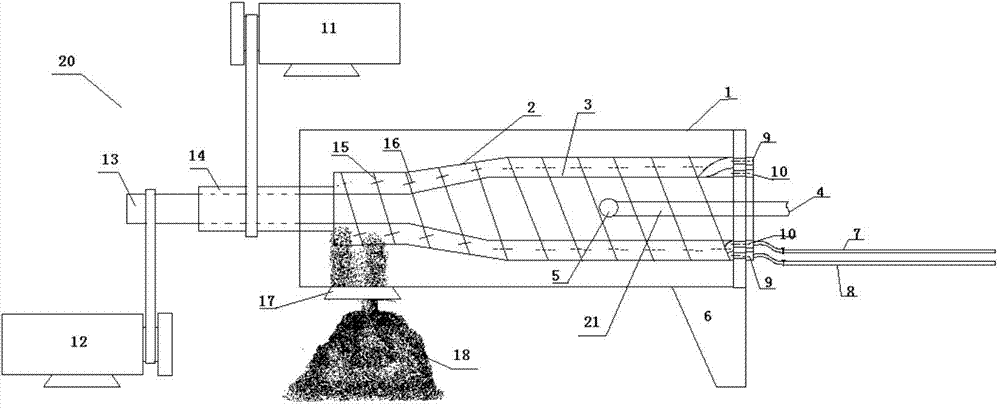

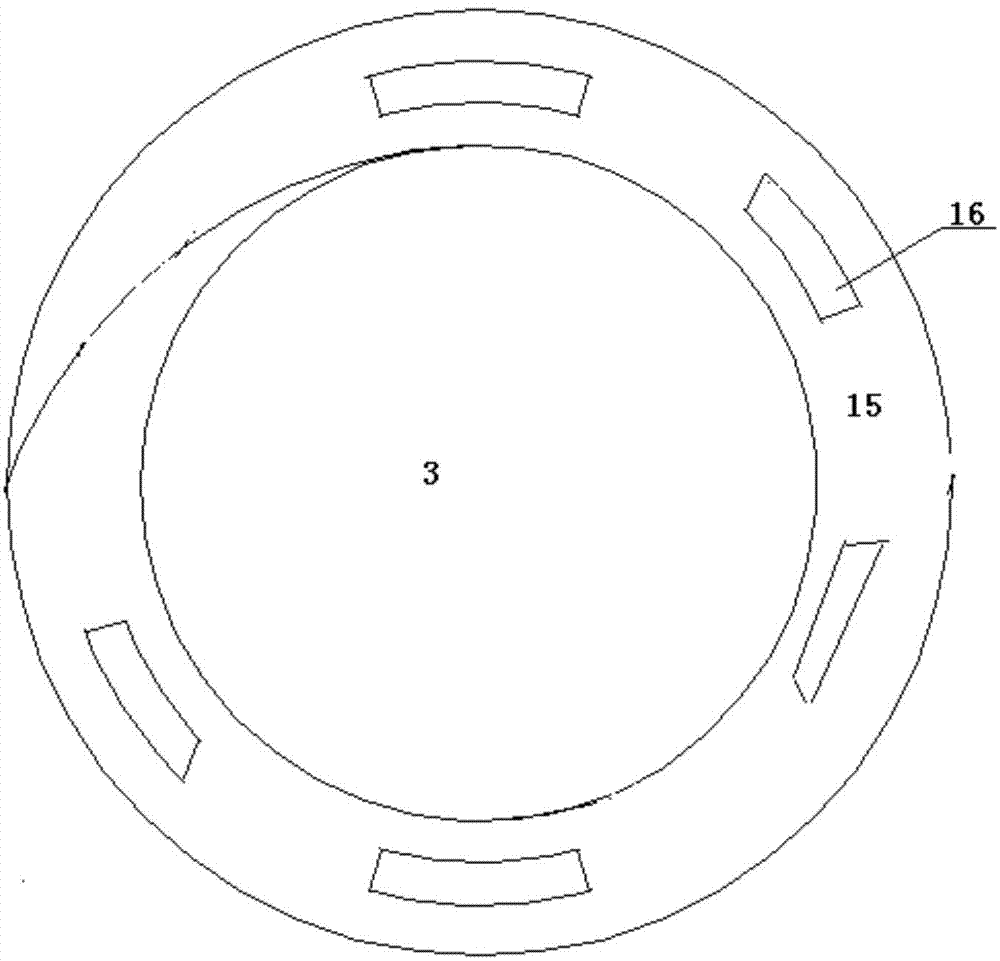

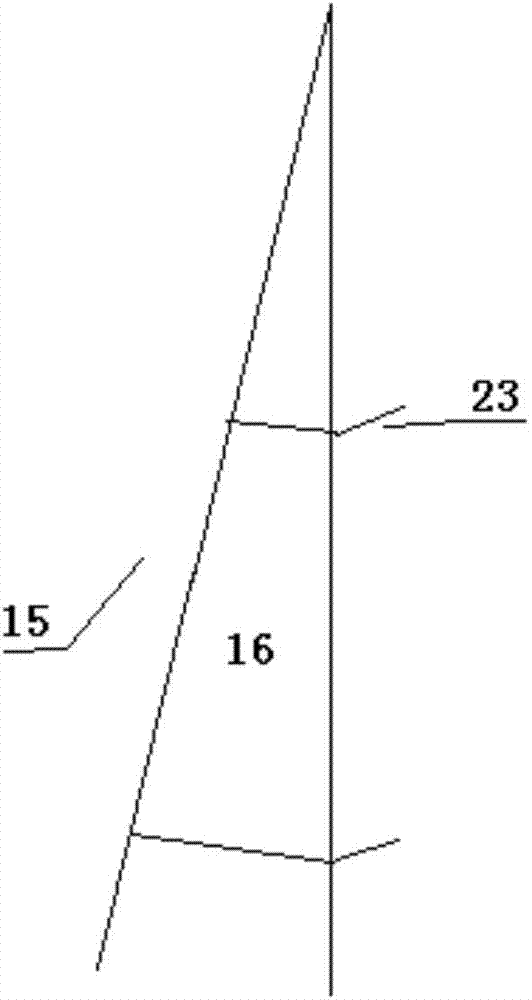

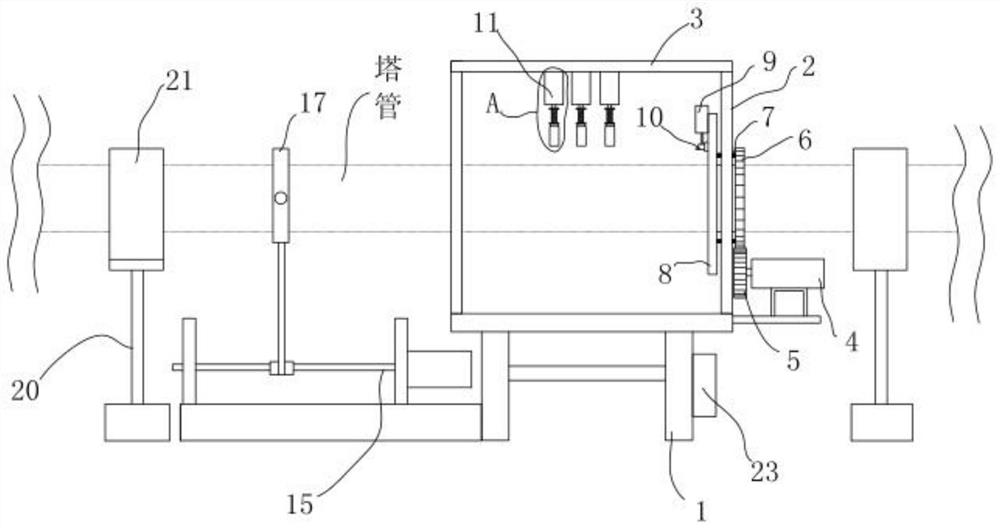

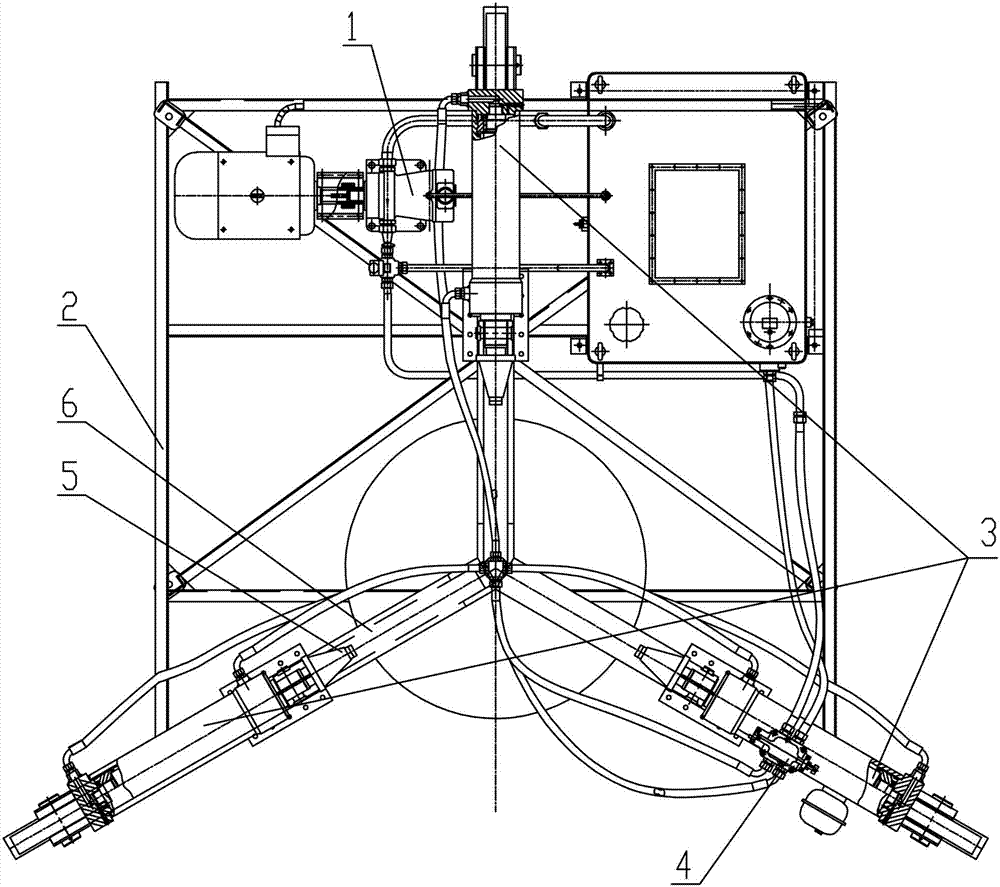

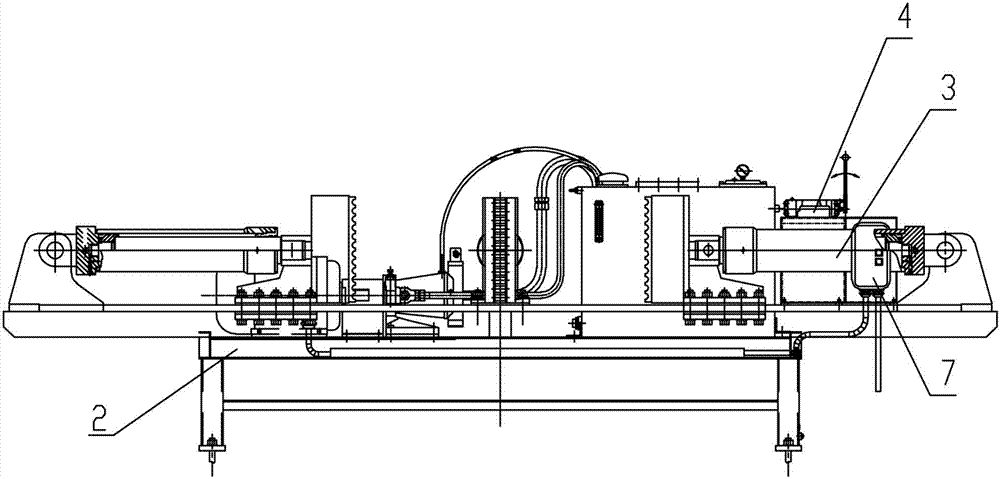

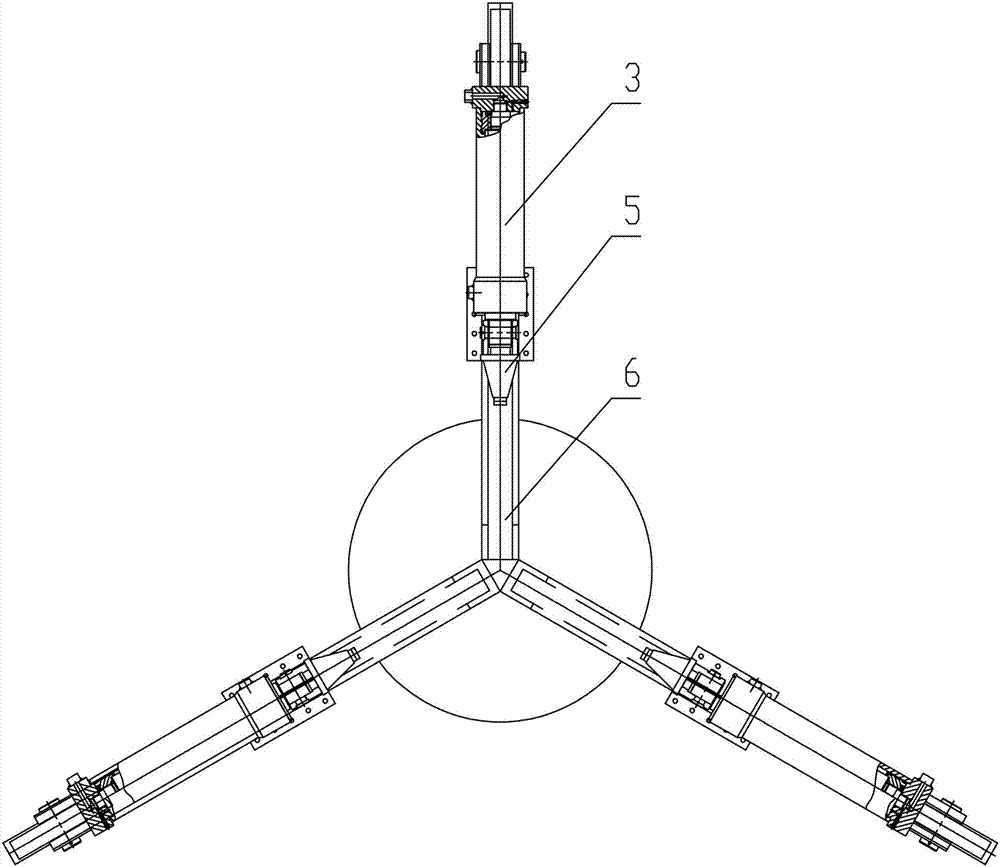

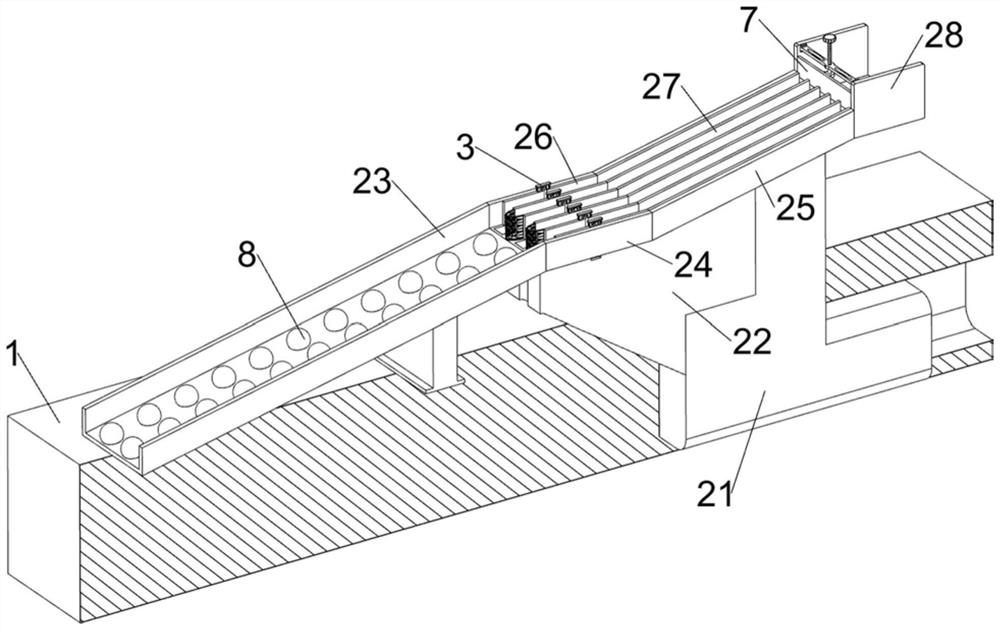

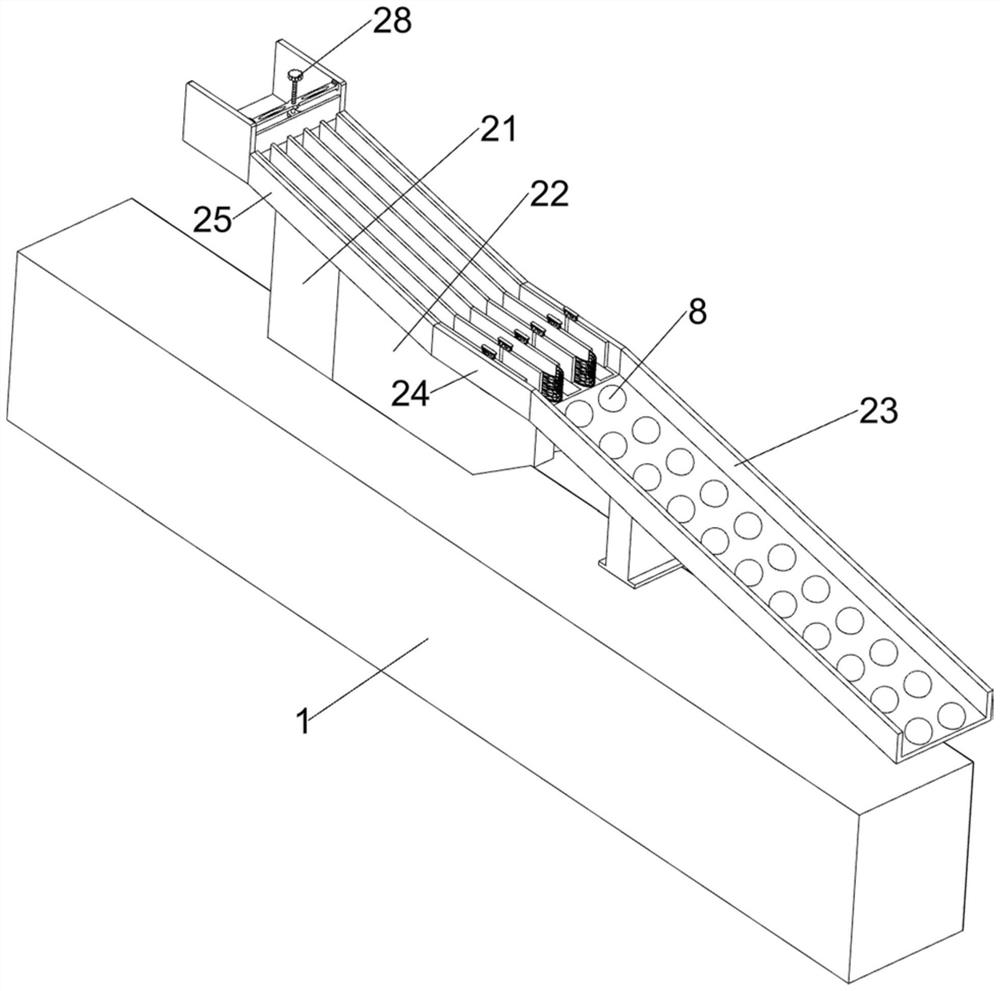

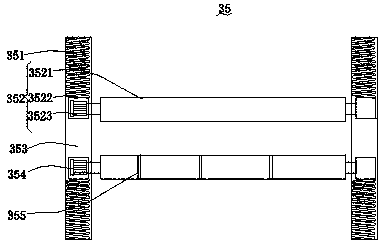

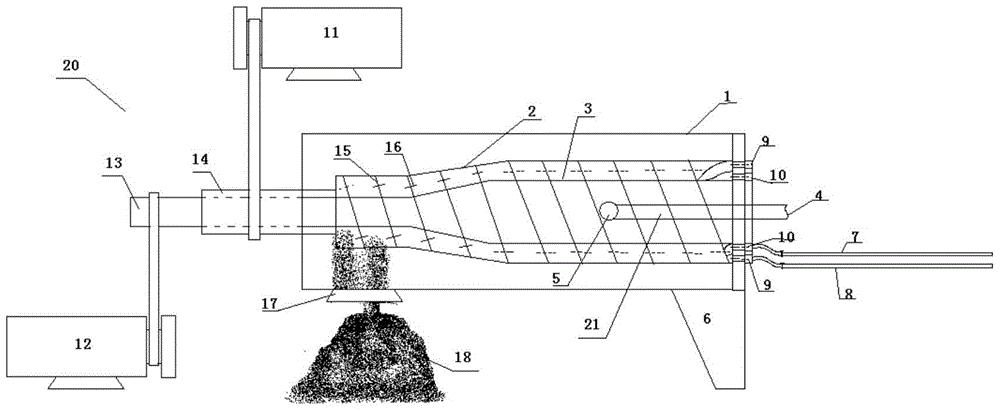

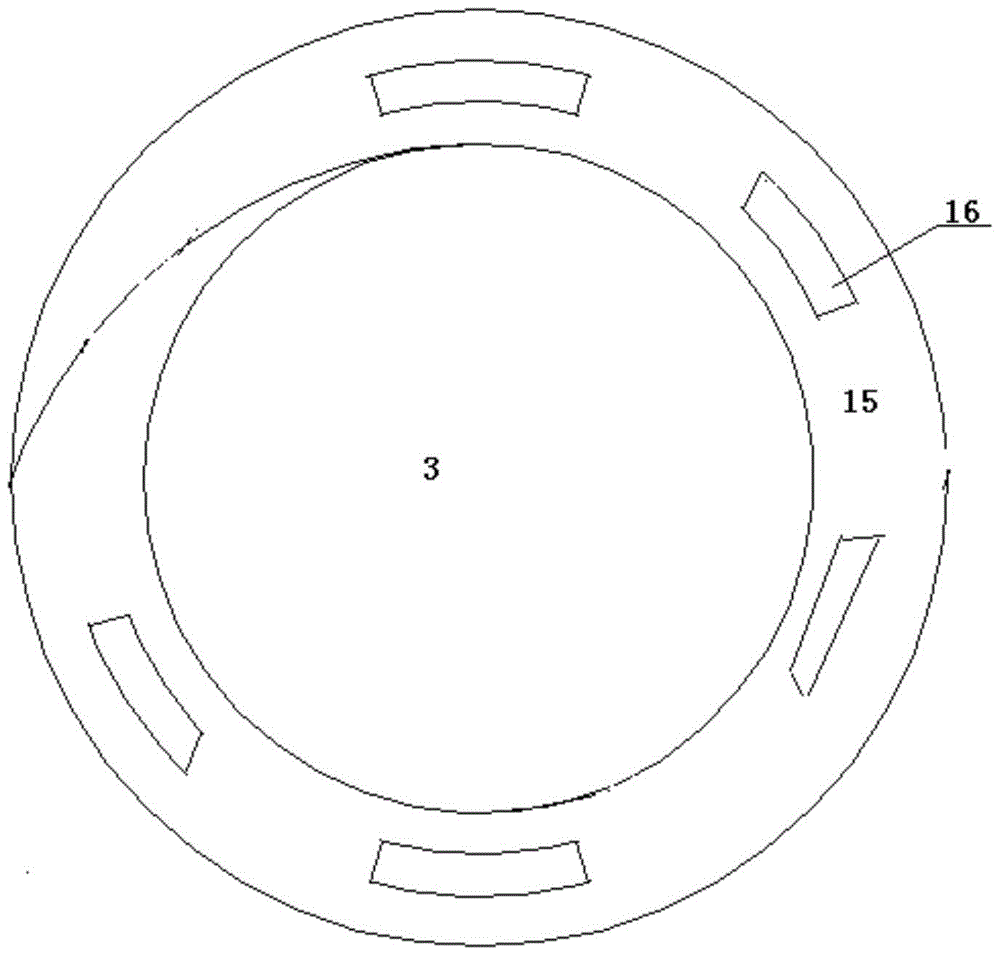

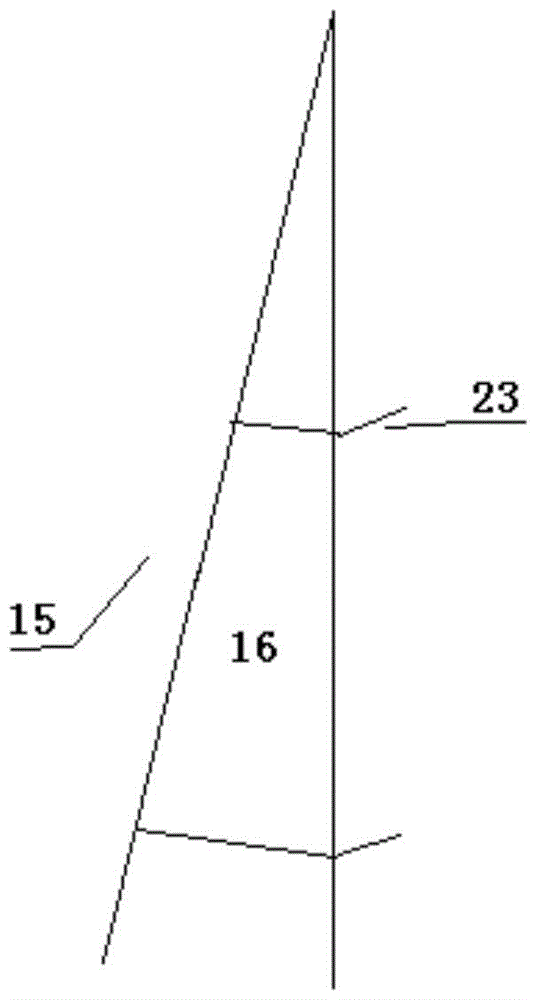

A tool and a detection method for detecting the bending rate of transmission line iron tower materials

ActiveCN110132191BImplement ring detectionEasy to deal with separatelyUsing subsonic/sonic/ultrasonic vibration meansControl systemTower

The object of the present invention is to provide a tool and a detection method for detecting the bending rate of the transmission line iron tower material, which are used to solve the technical problem of detecting the bending degree of the transmission line iron tower material. The utility model relates to a tool for detecting the bending ratio of iron tower materials of transmission lines, which includes a detection frame mechanism, a curvature detection mechanism, a graded and marked mechanism, a fixed-distance transmission mechanism, an end support mechanism and a control system. The curvature detection mechanism is used to detect the curvature of the tower tube; the classification labeling mechanism is used to grade and mark the tower tube according to the detection results of the curvature detection mechanism, so as to facilitate the classification and correction of the section of the tower tube; the fixed-distance transmission mechanism , used to convey the tower tube to the detection frame mechanism in gaps and segments, so as to facilitate the segmented detection of the tower tube; the end support mechanism is used to lift the tower tube to prevent the tower tube from being bent due to the weight during transmission, However, it interferes with its own curvature, causing detection errors.

Owner:QINGHAI POWER TRANSMISSION & TRANSFORMATION ENG +2

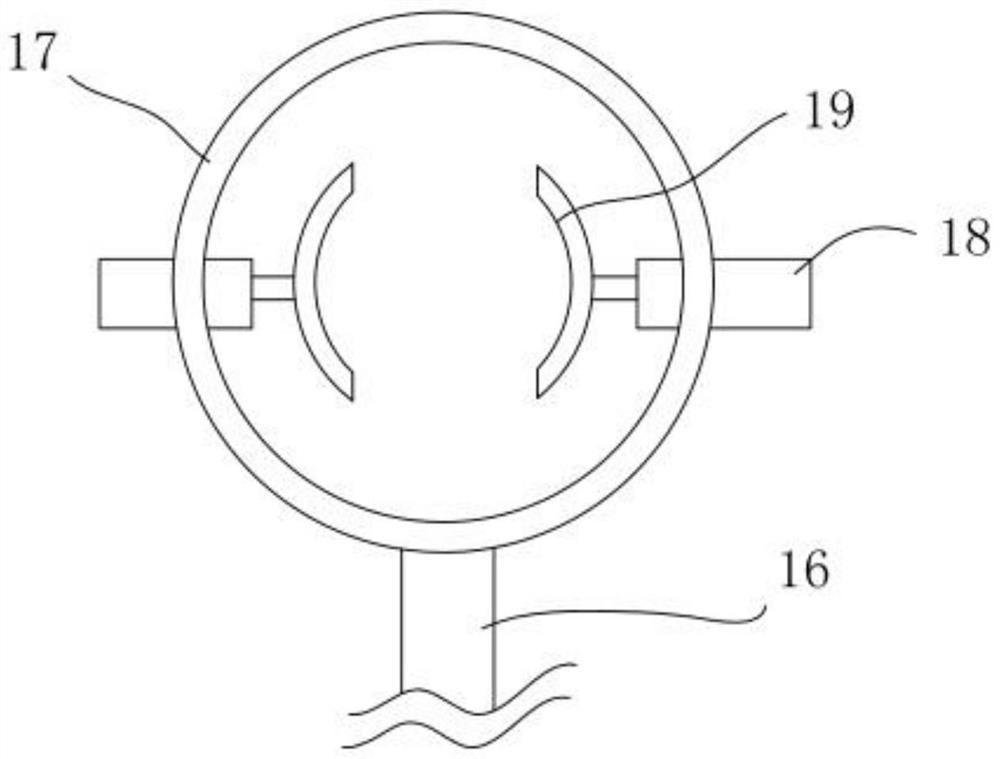

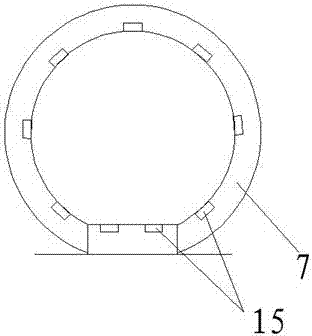

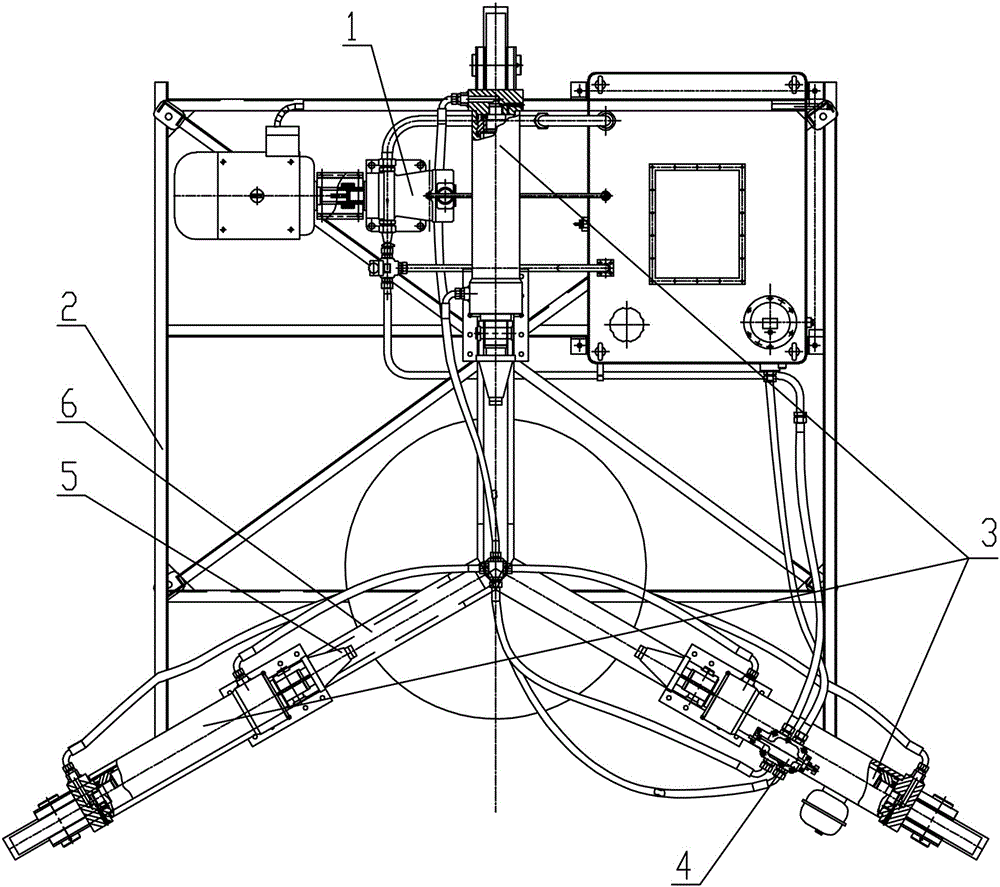

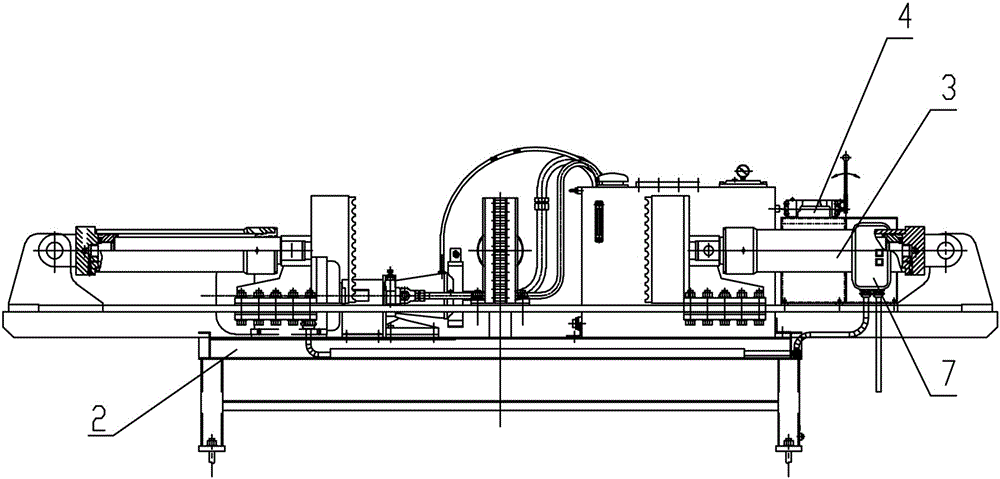

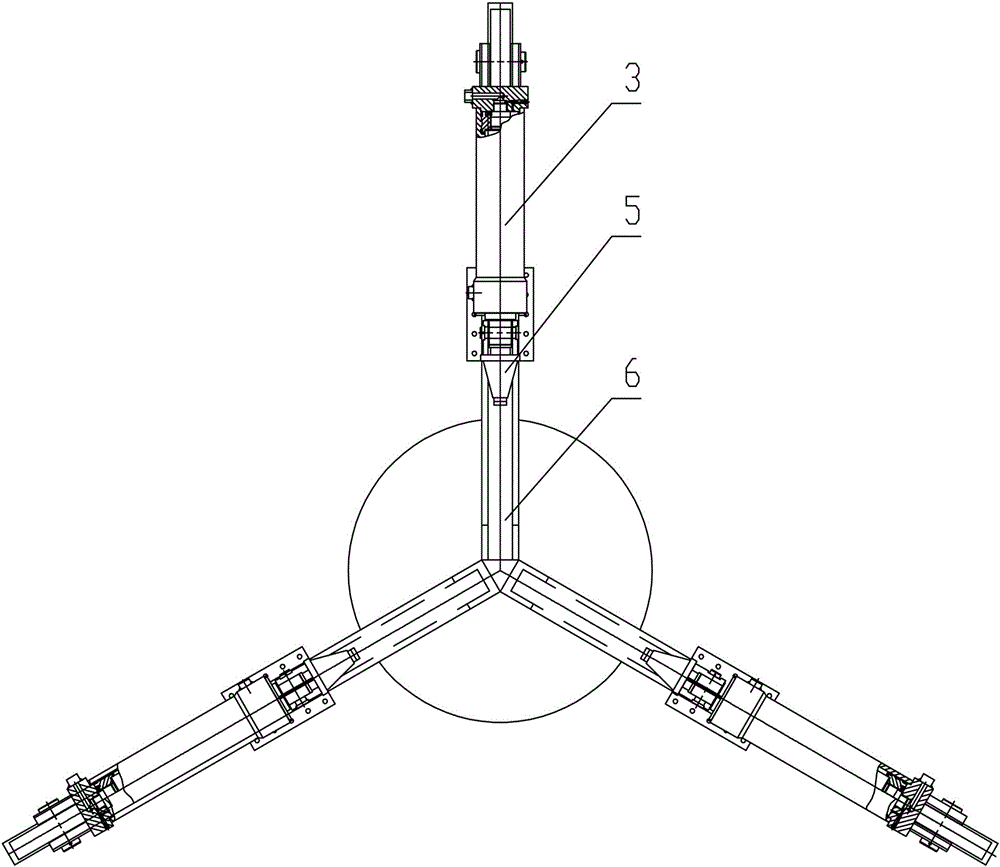

Scrap tire hub hydraulic detaching machine and scrap tire hub hydraulic detaching method

The invention discloses a scrap tire hub hydraulic detaching machine which comprises a rack. 3-4 hydraulic cylinders are oppositely and circumferentially arranged on the upper end face of the rack, and oil circuits of the hydraulic cylinders are connected with a hydraulic driving device through a reversing valve. One ends, close to the outer edge, of the hydraulic cylinders are fixedly connected with the rack, and one ends, close to the center, of the hydraulic cylinders are provided with pressure heads. Spaces for containing tires are reserved between the pressure heads, and guide rails which are arranged in a radial mode are arranged on the upper end face of the rack by corresponding to the pressure heads. The pressure heads are matched with the guide rails in a sliding mode. A method for detaching the scrap tires with the detaching machine comprises the following steps that the tires are placed between the pressure heads and the hydraulic driving device is started to extrude the tires centripetally; the reversing valve is reversed, and piston rods of the hydraulic cylinders retracts; by means of the steps, steel inner rings of the tires and rubber outer rings of the tires are naturally separated. By the adoption of the centripetal device and centripetal method, the steel inner rings of the tires are extruded and deformed through extrusion, and the diameters of the inner rings of the tires are shorted, and therefore the rubber outer rings of the tires can be conveniently separated from the steel inner rings of the tires.

Owner:宜昌力帝环保机械有限公司

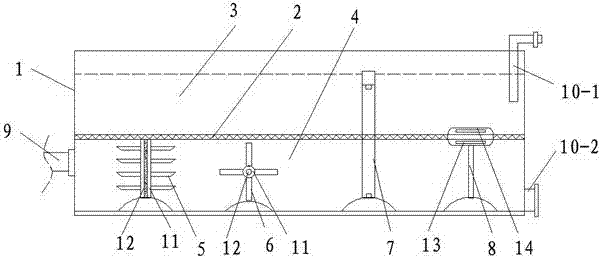

Multifunctional sludge treatment aeration tank

ActiveCN105036306BEasy separationEasy to deal with separatelyTreatment using aerobic processesSludge processingSludgeSewage

The invention discloses a multifunctional sludge treatment aeration tank. A separation screen horizontally arranged is arranged in the middle of an aeration tank body, and the tank body is divided into a sewage area and a sludge area through the separation screen. A feeding port and a discharging port are formed in the two ends of the tank body respectively. A first-level treatment device, a second-level treatment device, a third-level treatment device and a fourth-level treatment device are arranged between the feeding port and the discharging port in sequence. The first-level processing device is a perpendicular stirring paddle, the second-level treatment device is a transverse stirring paddle, the third-level treatment device is a ventilation ring, and the fourth-level treatment device is a T-shaped sterilization table. The perpendicular stirring paddle and the transverse stirring paddle are arranged in the sludge area. According to the multifunctional sludge treatment aeration tank, due to the combined action of the four sets of treatment devices and the separation screen, aeration of sewage and sludge can be completed in the aeration tank, meanwhile, primary separation operation and sterilization operation of sludge and sewage are completed, sludge and sewage are conveniently treated respectively, and the production technology for sewage and sludge is optimized.

Owner:TAIZHOU MING FENG TECH CO LTD RENEWABLE RESOURCES

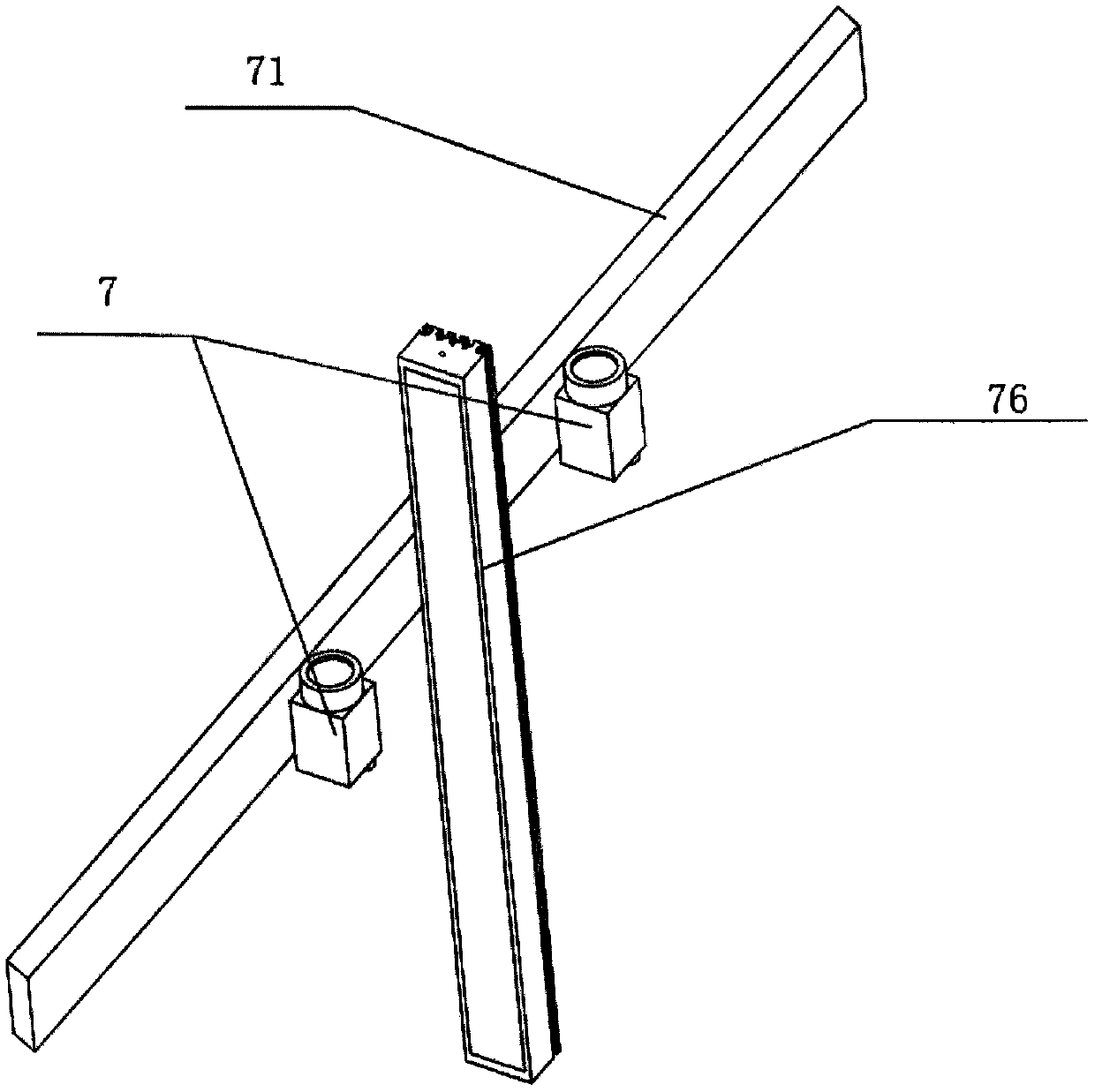

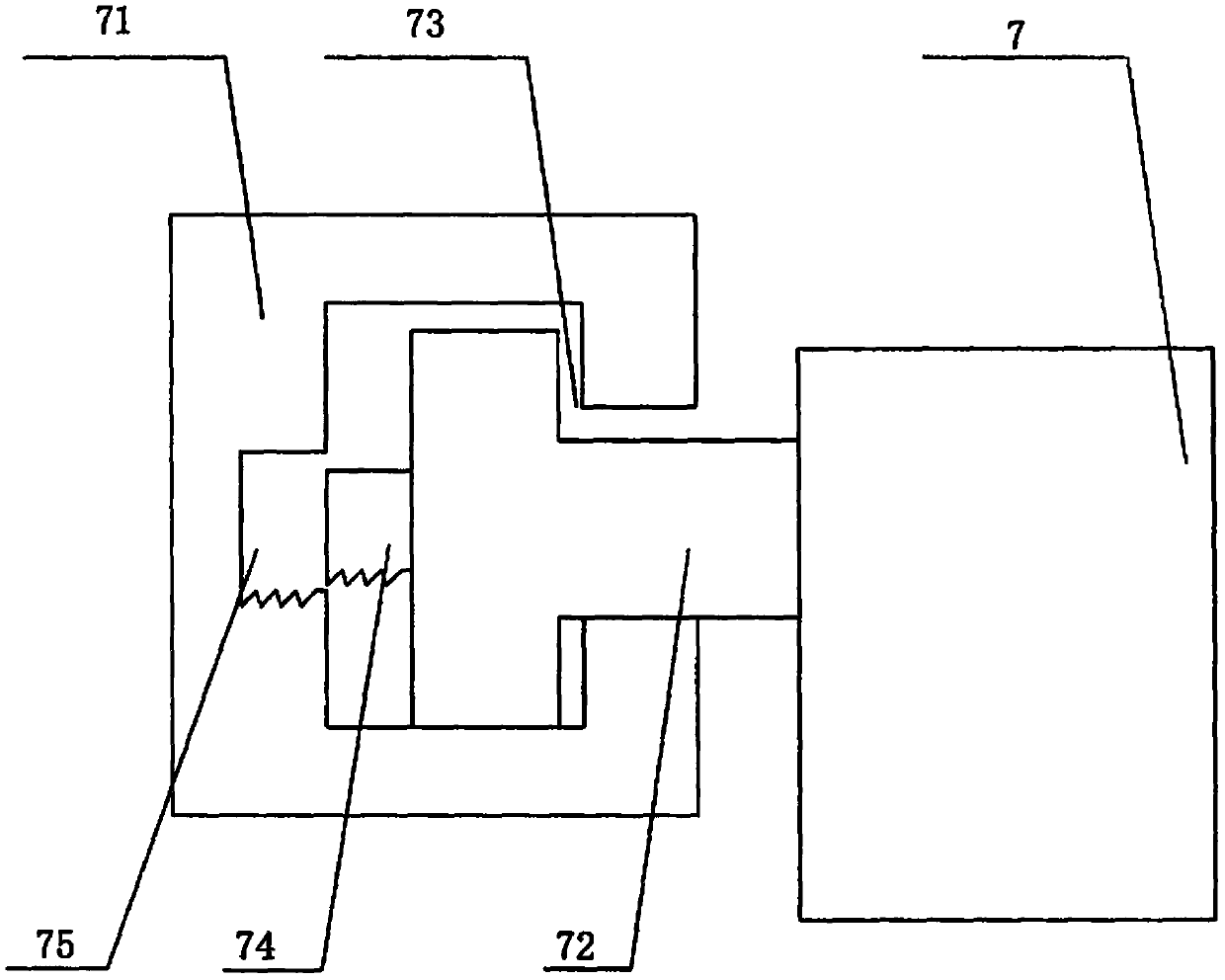

Fishing device for migratory fishes in estuary bay area

ActiveCN114128683AAvoid damageMaintain ecological balanceClimate change adaptationFishingMarine engineeringRiver bed

The invention relates to a fish catching device, in particular to a migratory fish catching device for an estuary bay area, which comprises a catching collecting frame, a supporting inclined frame, a backflow auxiliary frame, a slotted rectangular frame and the like, a fishing collecting frame is deeply buried in a riverbed, three supporting inclined frames are fixedly connected to the upper portion of the fishing collecting frame, at least one part of each supporting inclined frame is located in the riverbed, a backflow auxiliary frame is fixed to the surface of the riverbed through a limiting component and fixedly connected with the supporting inclined frames, and a slotted rectangular frame is fixedly connected to the upper portions of the supporting inclined frames. Through cooperation of the limiting columns and the partition plates, fish fries and large fishes can be separated, workers can conveniently treat the fish fries and the large fishes in the follow-up process, the fish fries can be effectively protected, and the workers can conveniently put the fish fries back into a river in the follow-up process to maintain ecological balance.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

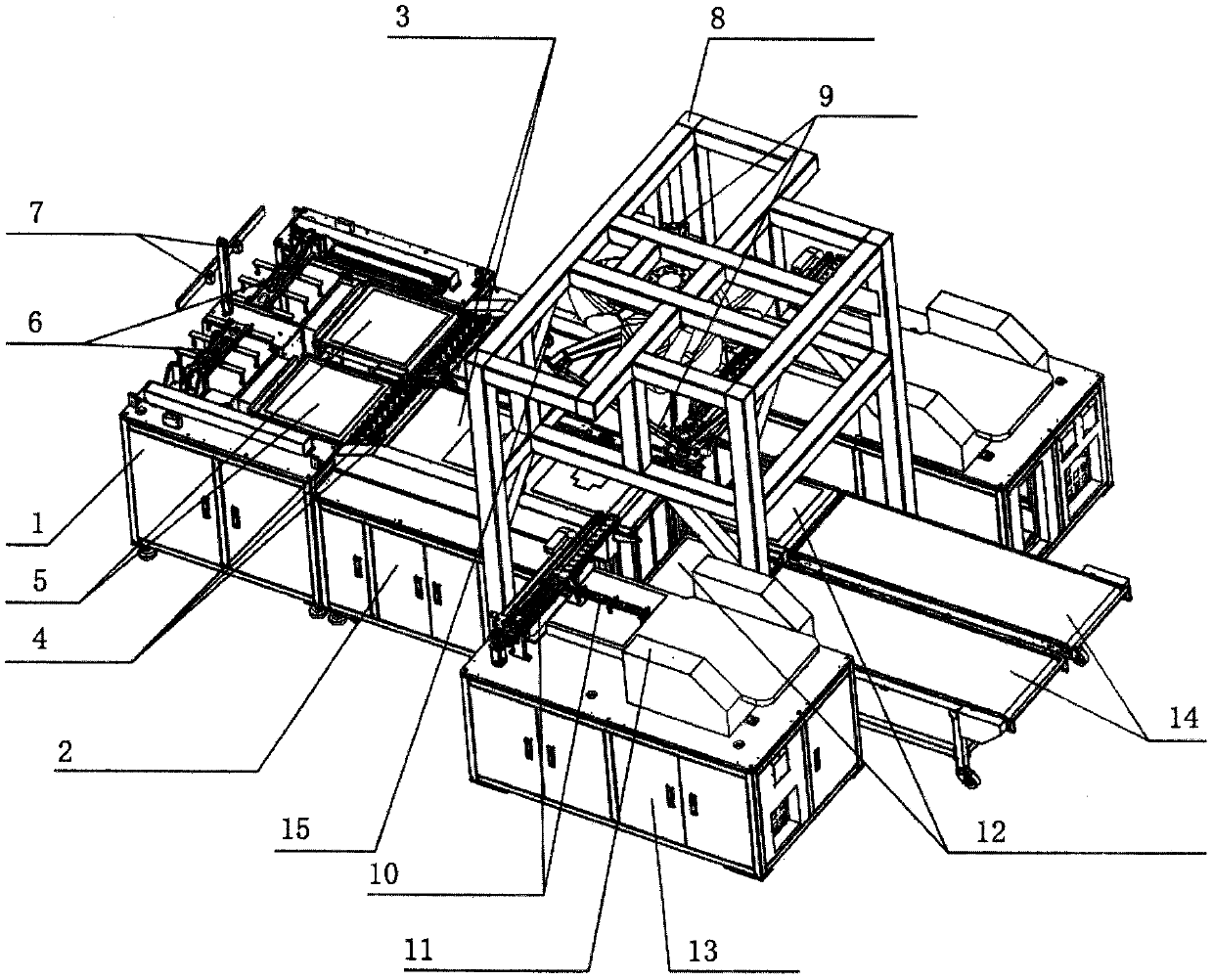

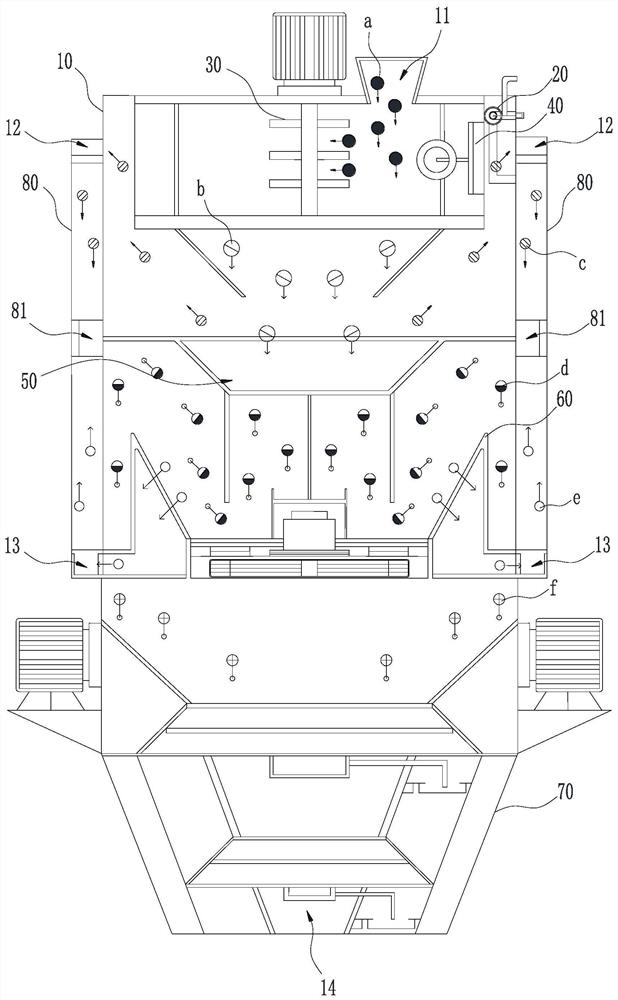

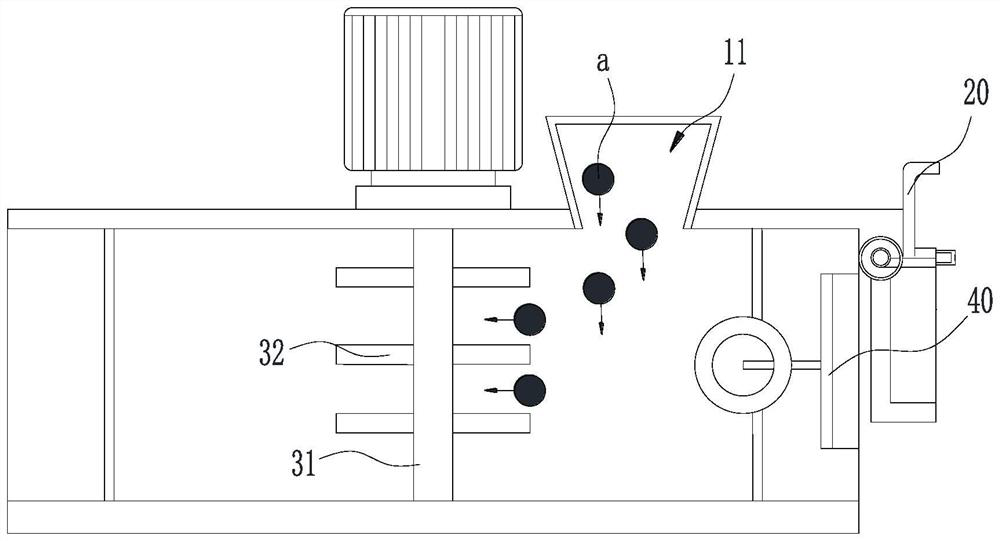

Full-intelligent refuse pretreatment device for refuse fermentation

The invention discloses a full-intelligent refuse pretreatment device for refuse fermentation. The full-intelligent refuse pretreatment device for refuse fermentation comprises a receiving tank, a first conveying belt, a large refuse sorting mechanism, side baffles, a screening conveying belt, a second conveying belt, a third conveying belt, a soft refuse outputting mechanism, springs, a first pressing mechanism, a rotating roller, sliding blocks, motors, sliding rails, a second pressing mechanism, conveying ropes, conveyor rollers, a first feeding hopper, a breaking belt machine, a fourth conveying belt, a vibrating motor, a second feeding hopper, a small refuse sorting mechanism, a winnowing mechanism, a waste discharging channel, a ventilating pipeline, a first fan, a waste discharginghopper, a screen, a second fan, a sorting box and a fifth conveying belt. According to the refuse pretreatment device for kitchen refuse fermentation, the large refuse sorting mechanism is used for sorting out large refuse, meanwhile, hard refuse and soft refuse can be separated according to the characteristics of the large refuse, the refuse can be fermented directly, separation after fermentation is not needed, and thus the separation cost and difficulty are reduced.

Owner:ANHUI ZHIXIN ENERGY TECH CO LTD

Scrap tire wheel hub hydraulic removal machine and method

The invention discloses a scrap tire hub hydraulic detaching machine which comprises a rack. 3-4 hydraulic cylinders are oppositely and circumferentially arranged on the upper end face of the rack, and oil circuits of the hydraulic cylinders are connected with a hydraulic driving device through a reversing valve. One ends, close to the outer edge, of the hydraulic cylinders are fixedly connected with the rack, and one ends, close to the center, of the hydraulic cylinders are provided with pressure heads. Spaces for containing tires are reserved between the pressure heads, and guide rails which are arranged in a radial mode are arranged on the upper end face of the rack by corresponding to the pressure heads. The pressure heads are matched with the guide rails in a sliding mode. A method for detaching the scrap tires with the detaching machine comprises the following steps that the tires are placed between the pressure heads and the hydraulic driving device is started to extrude the tires centripetally; the reversing valve is reversed, and piston rods of the hydraulic cylinders retracts; by means of the steps, steel inner rings of the tires and rubber outer rings of the tires are naturally separated. By the adoption of the centripetal device and centripetal method, the steel inner rings of the tires are extruded and deformed through extrusion, and the diameters of the inner rings of the tires are shorted, and therefore the rubber outer rings of the tires can be conveniently separated from the steel inner rings of the tires.

Owner:宜昌力帝环保机械有限公司

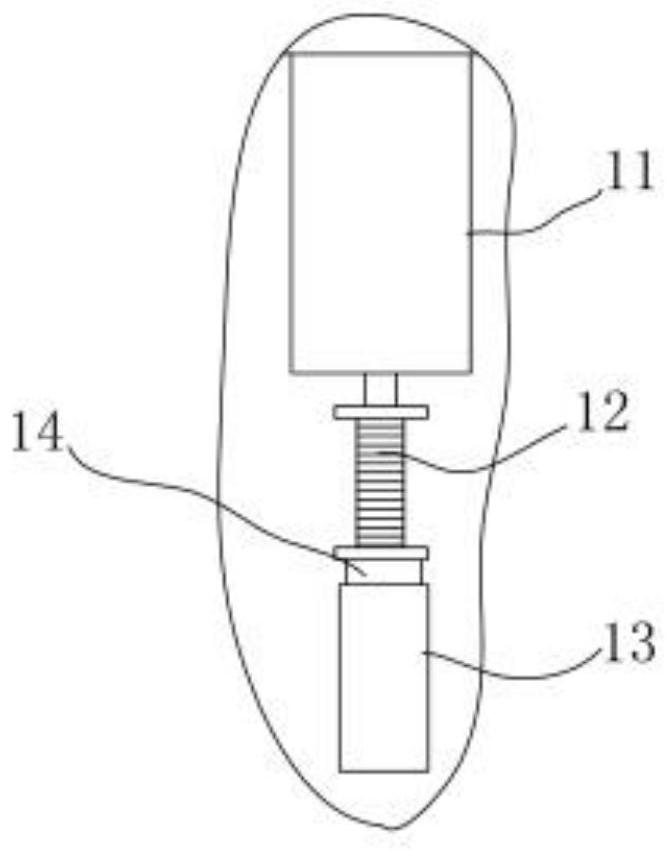

Medical waste treatment device having good pulverizing effect and high safety

InactiveCN108393332AEasy to deal with separatelyAchieve disinfectionSolid waste disposalMedical wasteElectric machinery

The invention discloses a medical waste treatment device having a good pulverizing effect and high safety. The medical waste treatment device comprises a body, a supporting arm, a base, a material inlet, a separating cavity, a sewage discharge port and a first rotating shaft; the base is arranged at the bottom of the body; the supporting arm is arranged at the upper part of the left side of the base; the right side of the supporting arm is fixedly connected with a pulverizing cavity; a material discharge port is formed in the lower part of the pulverizing cavity; the separating cavity is formed on the right side of the pulverizing cavity; the sewage discharge port is formed in the lower part of the separating cavity; the material inlet is formed in the upper part of the right side of the separating cavity; a motor is arranged on the right side of the body; and the first rotating shaft is arranged at the upper part of the motor. The medical waste treatment device is reasonable in designand simple to operate; residues of medical waste can be prevented from remaining on a filtering screen; solid-liquid separation can be carried out on the medical waste; the medical waste is subjectedto high-temperature disinfection effectively, and the life safety of operators is ensured; and the medical waste treatment device is suitable for popularization.

Owner:季元吉

Flocculation grading dehydration device

ActiveCN113354142ATo achieve the purpose of screeningImprove dehydration effectWater/sewage treatment by centrifugal separationSettling tank with pumpFlocculationEngineering

The invention relates to the technical field of solid-liquid separation, in particular to a flocculation grading dehydration device, which is characterized in that an initial material is fed through a feeding hole in the upper end of a tank body, then a chemical agent is added into the initial material through a chemical agent adding mechanism, after the initial material is subjected to a flocculation reaction, a lower sediment material sinks into a sedimentation tank, and an upper liquid overflows through an overflow hole; in the centrifugal dewatering area, a screen basket is rotated, so that sediment materials falling into the screen basket do centrifugal movement, water in the sediment materials is moved into a flow guide cavity through a liquid through hole in the side wall of the screen basket, liquid in the flow guide cavity flows to a centrifugal liquid outlet, and the dewatered materials in the screen basket are moved out of the screen basket after centrifugal movement; in the particle screening area, the screening mechanism screens particles of different size fractions in the dehydrated materials discharged by the screening basket, and water screened out in the screening process descends and is discharged through a water outlet; and liquid discharged from the centrifugal liquid outlet and the overflow port is collected by the overflow dispersion pipeline and then is discharged from a mixed liquid outlet of the overflow dispersion pipeline.

Owner:ANHUI UNIV OF SCI & TECH

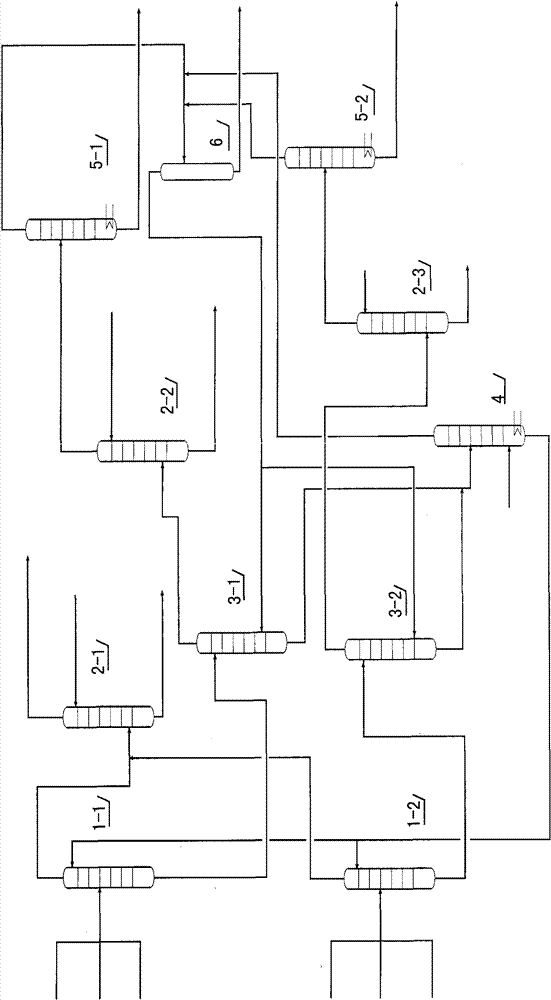

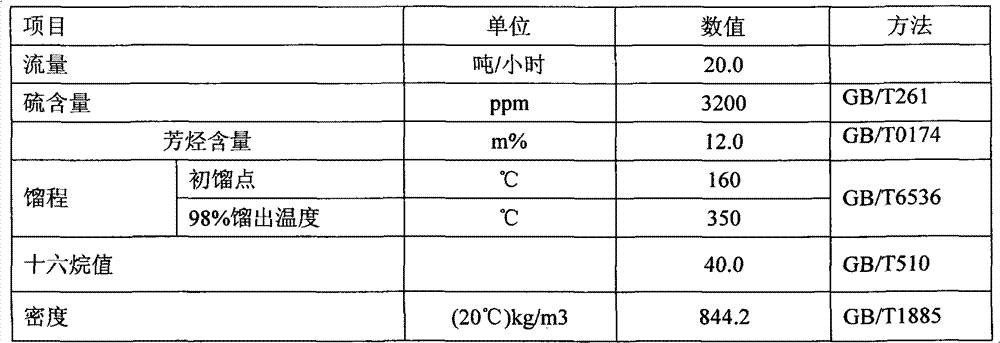

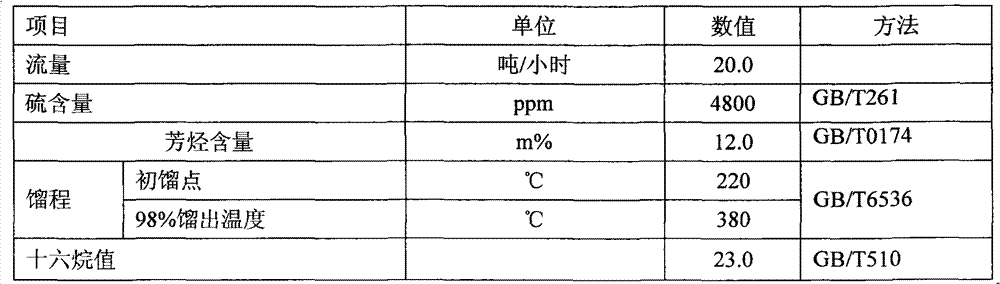

Method for preparing high-quality diesel oil by increasing cetane number through non-hydrodesulfurization

InactiveCN102102031BIncrease cetane numberLowering the freezing pointTreatment with plural parallel refining stagesHydrodesulfurizationAromatic hydrocarbon

Owner:BEIJING GRAND GOLDEN BRIGHT ENG & TECH

A three-phase separation treatment system for oil sludge and sand and its application

ActiveCN104743757BEfficient separationEfficient three-phase centrifugal separationSludge treatmentRefluxOil sludge

The invention relates to an oil-sludge-sand three-phase separation treatment system which comprises a heating and stirring kettle for heating and stirring materials and a three-phase separation machine communicated with the heating and stirring kettle. According to the system, the rotary stirring of the materials is enhanced by a centrifugal barrel and a stirring rotating shaft barrel, which rotate in opposite directions, and meanwhile, the materials are subjected to three-phase separation under a centrifugal force generated by high-speed rotation of the centrifugal barrel; since a screw blade is mutually attached to the inner wall of the centrifugal barrel, a sand phase is conveyed to a sand phase discharge opening as the screw blade rotates, and an oil phase and a water phase are closely attached to the screw blade under the action of the centrifugal force and finally flow back to the large-diameter end of the centrifugal barrel along liquid-phase reflux holes in the screw blade; and according to the stratification condition of the water phase and the oil phase on the wall of the centrifugal barrel, namely that the water phase is closely attached to the inner wall of the centrifugal barrel under the action of the centrifugal force, followed by the oil phase, a water phase outlet and an oil phase outlet are concentrically formed in the large-diameter end of the centrifugal barrel respectively so as to lead the water phase and the oil phase out respectively.

Owner:威海恒荣环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com