Method for recovering and regenerating copper in waste etching liquid

A technology of etching waste liquid and acidic etching waste liquid, which is applied in the direction of photographic process, instrument, photographic auxiliary process, etc., can solve the problems of environmental hazards, environmental pollution, waste of resources, etc., achieve recycling, improve purity, and realize industrialized production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

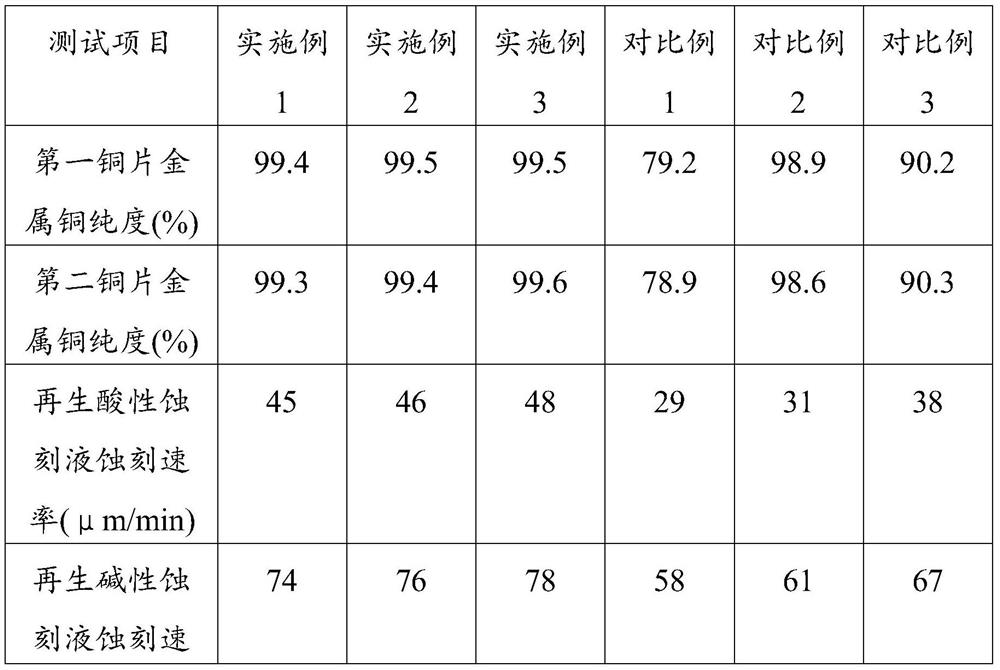

Embodiment 1

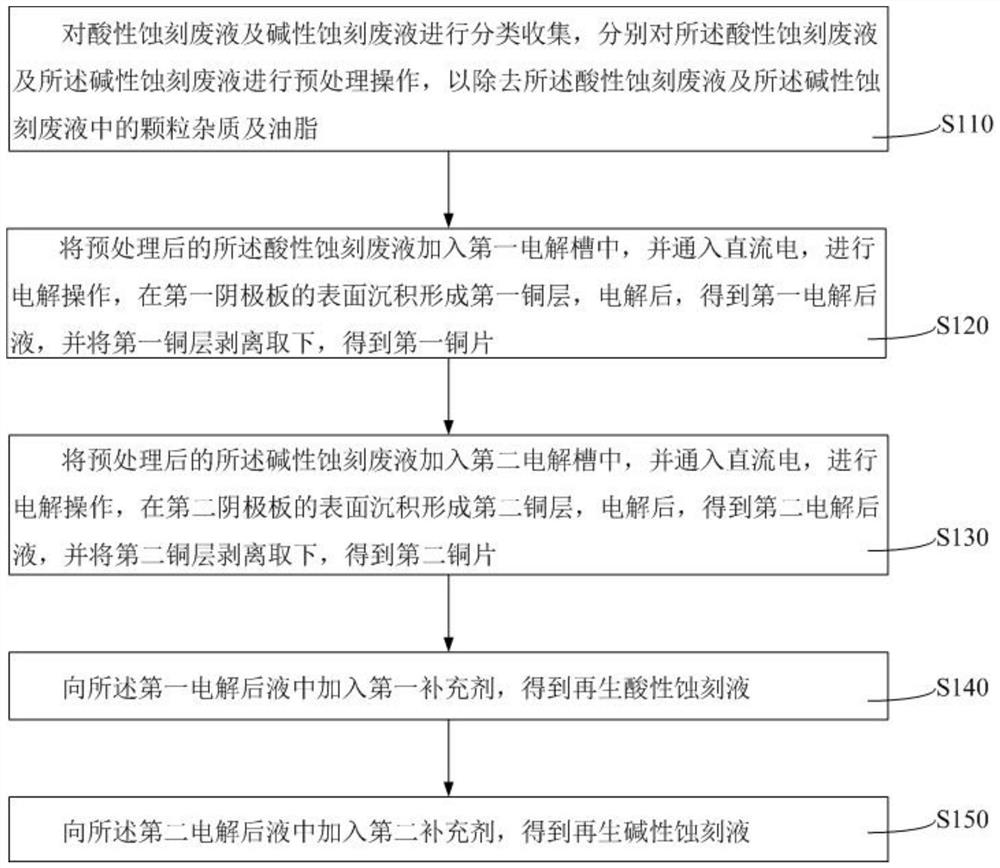

[0054] The acidic etching waste liquid and the alkaline etching waste liquid are classified and collected, and the oil suction box is first put into the liquid surface of the acidic etching waste liquid and the alkaline etching waste liquid respectively to remove grease, and the oil suction box is set There is an accommodating cavity, and an oil-absorbing layer is arranged in the accommodating cavity, and a plurality of oil filter pores are opened on the side wall of the oil-absorbing box, and each of the oil filter pores communicates with the accommodating cavity respectively, and the oil-filtering pores are respectively connected to the The acidic etching waste liquid and the alkaline etching waste liquid are filtered to remove particulate impurities;

[0055] Add the pretreated acidic etching waste liquid into the first electrolytic cell, and pass direct current to carry out electrolytic operation, control the electrolytic current density to 180A / m2, and the electrolytic tem...

Embodiment 2

[0060] The acidic etching waste liquid and the alkaline etching waste liquid are classified and collected, and the oil suction box is first put into the liquid surface of the acidic etching waste liquid and the alkaline etching waste liquid respectively to remove grease, and the oil suction box is set There is an accommodating cavity, and an oil-absorbing layer is arranged in the accommodating cavity, and a plurality of oil filter pores are opened on the side wall of the oil-absorbing box, and each of the oil filter pores communicates with the accommodating cavity respectively, and the oil-filtering pores are respectively connected to the The acidic etching waste liquid and the alkaline etching waste liquid are filtered to remove particulate impurities;

[0061] Add the pretreated acidic etching waste liquid into the first electrolytic tank, and pass through direct current to carry out electrolytic operation, control the electrolytic current density to 190A / m2, and the electrol...

Embodiment 3

[0066] The acidic etching waste liquid and the alkaline etching waste liquid are classified and collected, and the oil suction box is first put into the liquid surface of the acidic etching waste liquid and the alkaline etching waste liquid respectively to remove grease, and the oil suction box is set There is an accommodating cavity, and an oil-absorbing layer is arranged in the accommodating cavity, and a plurality of oil filter pores are opened on the side wall of the oil-absorbing box, and each of the oil filter pores communicates with the accommodating cavity respectively, and the oil-filtering pores are respectively connected to the The acidic etching waste liquid and the alkaline etching waste liquid are filtered to remove particulate impurities;

[0067] Add the pretreated acidic etching waste liquid into the first electrolytic tank, and pass through direct current to carry out electrolytic operation, control the electrolytic current density to 195A / m2, and the electrol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com