Laser engraving back lacquered mirror

A laser engraving and mirror technology, applied in decorative arts, processes for producing decorative surface effects, special decorative structures, etc., can solve the problems of difficult to achieve delicate effects, time-consuming and laborious, and single mirror expressiveness. Effect of Mirror Decorative Puzzle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

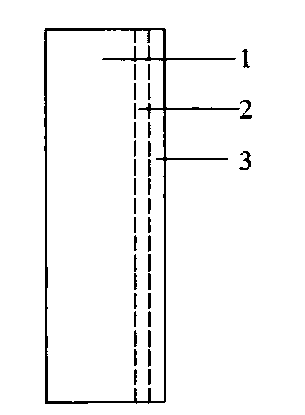

[0016] The laser engraving back paint mirror of the present invention comprises an eyeglass 1, and eyeglass 1 can adopt traditional mirror coating technology to realize, and 2, eyeglass 1 is glass 2 (or other substrates) silver-plated or aluminized film layer 3 and glass form a whole, The back paint 4 is sprayed on the whole surface, and the protection of the back paint 4 increases reflection and prevents oxidation. The surface layer 3 or back paint 4 is evaporated by laser beam, and the processing depth can be effectively controlled by using the laser beam. Due to the different materials, the glass substrate 2 is not damaged and the line width can be controlled to obtain text 5 and pattern 6, and local mirror reflection changes. , to achieve mirror decoration effect.

[0017] Wherein, the lens 1 is integral and has a reflective function. The glass 2 is attached with a reflective film layer 3 and a back paint 4 as the substrate surface, and the laser is to utilize a controlla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com