Micro-ring assistant ring mirror structure

A micro-ring and ring-mirror technology, used in light guides, optics, instruments, etc., can solve the problems of complex fabrication, unrealizable, unapplied wavelength selection, etc., to achieve a large wavelength tunable range, good process compatibility, increase wavelength The effect of (or frequency) adjustable function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

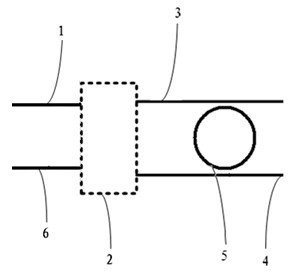

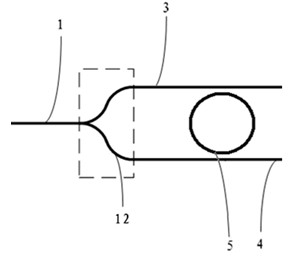

[0035] like figure 2 As shown, the device adopts a symmetrical Y branch structure 12 as a beam splitting coupling structure. The device is made of silicon-on-insulator (SOI) material, the thickness of the top silicon layer is 220 nm, and the thickness of the silicon dioxide buried layer is 1 μm. Using CMOS technology, through deep ultraviolet lithography and silicon dry etching, a ridge-shaped optical waveguide with a width of 400nm and a depth of 180nm is fabricated to form a figure 2 The device structure shown. The optical microring in the device is an optical waveguide ring with a radius of 5 μm. The gap between the microring and the two parallel waveguides is 180 nm. The Y branch structure is composed of S-shaped bends with a length of 25 μm.

[0036] After silicon dry etching is completed, a 1 μm silicon dioxide layer is covered by chemical vapor deposition. By sputtering, photolithography, and etching, the heating electrodes corresponding to the microrings are fab...

Embodiment 2

[0039] like Figure 4 As shown, the device uses a symmetrical X-cross junction structure 22 as the beam splitting coupling structure. The device is made of glass. Using buried ion exchange technology, a buried optical waveguide with a width of 10 μm and a depth of 18 μm is produced, forming Figure 4 The device structure shown. The optical microring in the device is a racetrack-shaped optical waveguide closed loop with a radius of 5mm. The gap between the microring and the two parallel waveguides is 3 μm. The widths of the asymmetric side waveguides of the X-cross junction structure are 8 μm and 12 μm, respectively, and the branch angle is 0.1 degree. The width of the symmetrical side waveguide is 10 μm, and the branch angle is 1 degree.

[0040] Thus, the auxiliary ring mirror with micro ring is completed. The ring mirror does not need to use the fine process required for Bragg grating production, has a reflectivity of 98%, and the Q value of the filter spectrum is great...

Embodiment 3

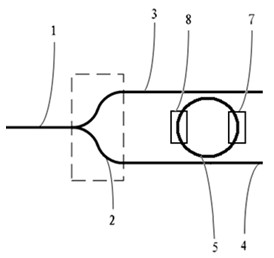

[0042] like Figure 5 As shown, the device uses a directional coupler structure 32 as a beam splitting coupling structure. The device is made of lithium niobate. Using titanium diffusion technology, a diffused optical waveguide with a width of 6 μm is produced to form a Figure 5 The device structure shown. The optical microring in the device is an optical waveguide ring with a radius of 500 μm. The gap between the microring and the two parallel waveguides is 2 μm. The waveguide gap of the directional coupler structure is 3 μm, and the length is 500 μm.

[0043] Thus, the auxiliary ring mirror with micro ring is completed. The ring mirror does not need to use the fine process required for Bragg grating production, has a reflectivity of 98%, and the Q value of the filter spectrum is greater than 1500.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com