Seat with headrest

A headrest and seat technology, which is applied to vehicle seats, special positions of vehicles, transportation and packaging, etc. It can solve the problems of difficult adjustment, lowering of the headrest, inconvenient use, etc., and achieves easy height adjustment, comfortable head, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

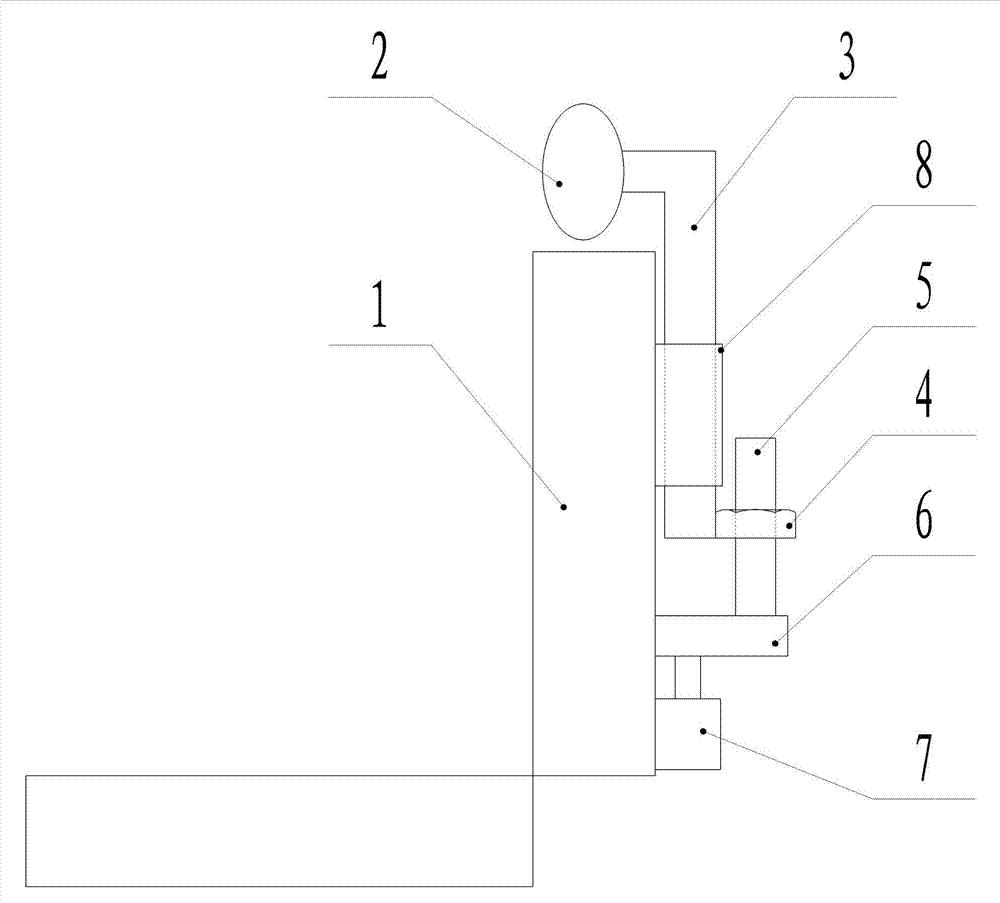

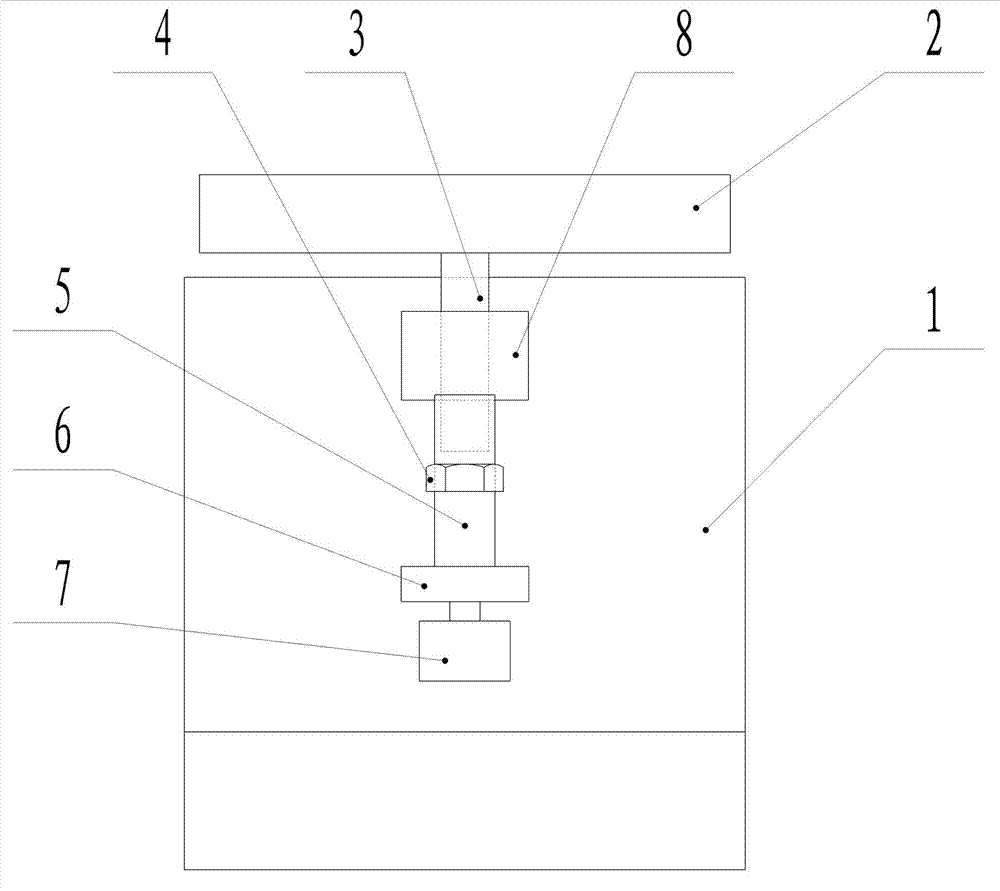

[0022] Reference figure 1 figure 2 , A seat with a headrest, comprising a backrest 1 and a headrest 2 arranged above the backrest 1. The headrest 2 is connected with a lifting positioning mechanism.

[0023] The lifting positioning mechanism includes a pillar 3, a nut 4, a worm 5 and a motor 7. The pillar 3 is fixedly connected to the nut 4, the nut 4 is matched with the worm 5, and the worm 5 is connected to the motor 7 through a reducer 6;

[0024] The headrest 2 is connected with a pillar 3, the pillar 3 passes through a sleeve 8 arranged on the backrest 1, and the pillar 3 can move up and down in the sleeve 8.

[0025] When in use, the motor 7 drives the worm 5 to rotate, so that the pillar 3 fixed on the nut 4 moves up and down with the rotation of the worm 5, so that the headrest 2 moves up and down to achieve stepless lifting positioning.

[0026] The headrest 2 is a long strip with a height of 2-6cm, which is 5cm in this example.

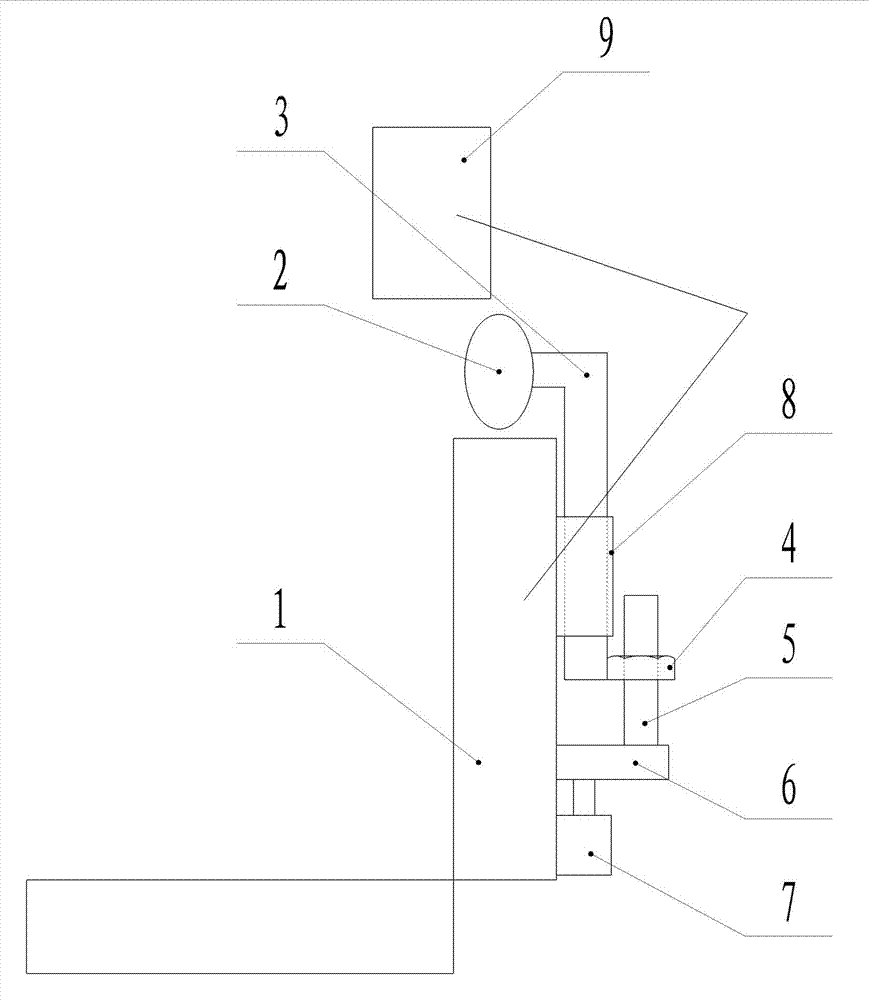

[0027] Such as image 3 As shown, in order to ...

Embodiment 2

[0029] Reference Figure 4 The lifting positioning mechanism includes a pillar, a nut 4, a worm 5 and a motor 7. There are two pillars, namely the first pillar 3-1 and the second pillar 3-2. The two pillars are connected by a connecting rod 10, and the connecting rod 10 and the nut 4 Fixed connection, nut 4 is matched with worm 5, worm 5 is connected with motor 7;

[0030] The headrest 2 is connected with two pillars, which respectively pass through two sleeves arranged on the backrest 1, namely the first sleeve 8-1 and the second sleeve 8-2. The pillars can move up and down in the sleeves. , The rest is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com