Computer jacquard machine and transmission mechanism thereof

A computerized jacquard machine and transmission mechanism technology, applied in the direction of jacquard machine, textile, textile and paper making, etc., can solve the problem of inconvenient maintenance, and achieve the effect of reducing deformation, shortening length and shortening modification time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

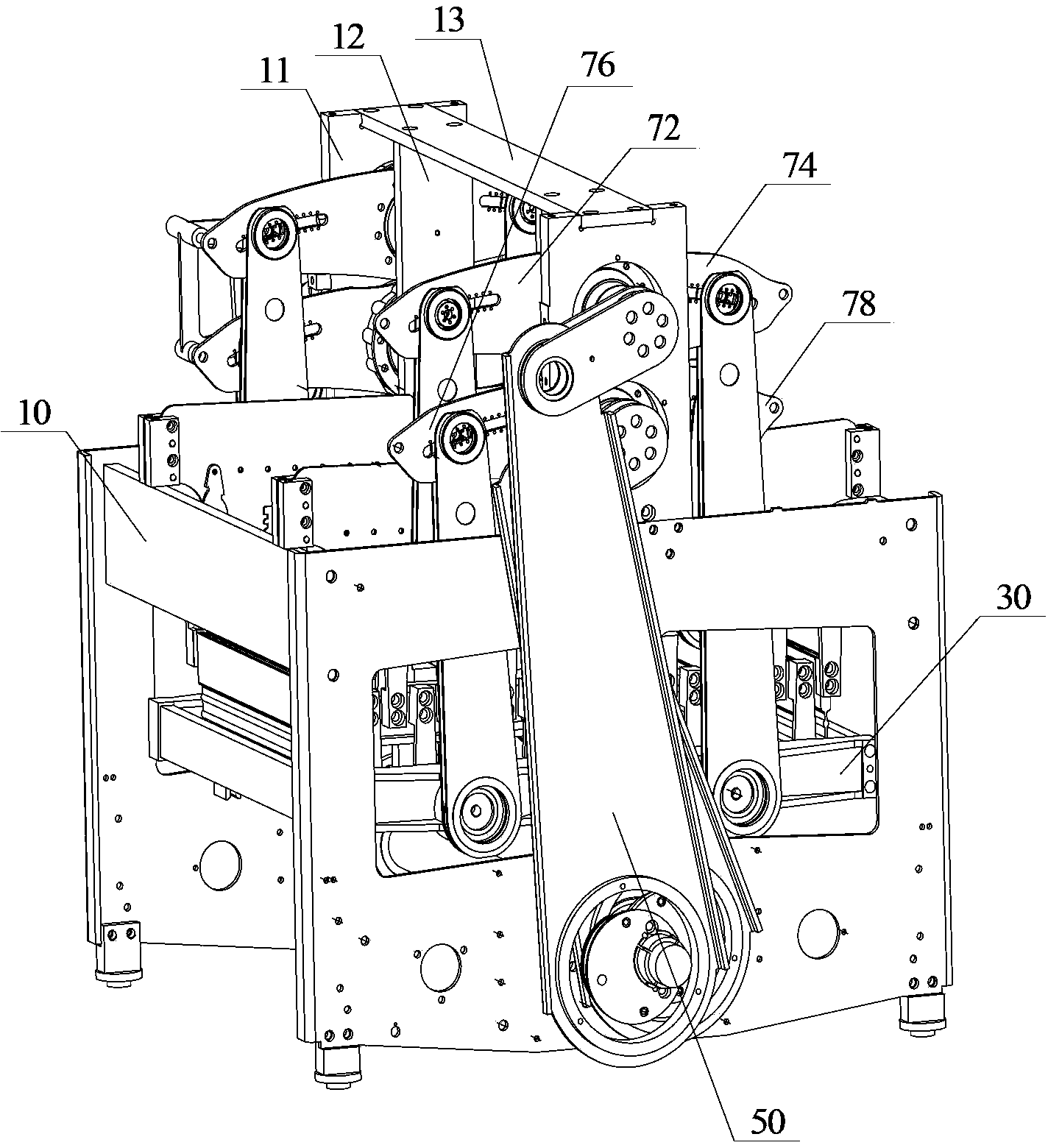

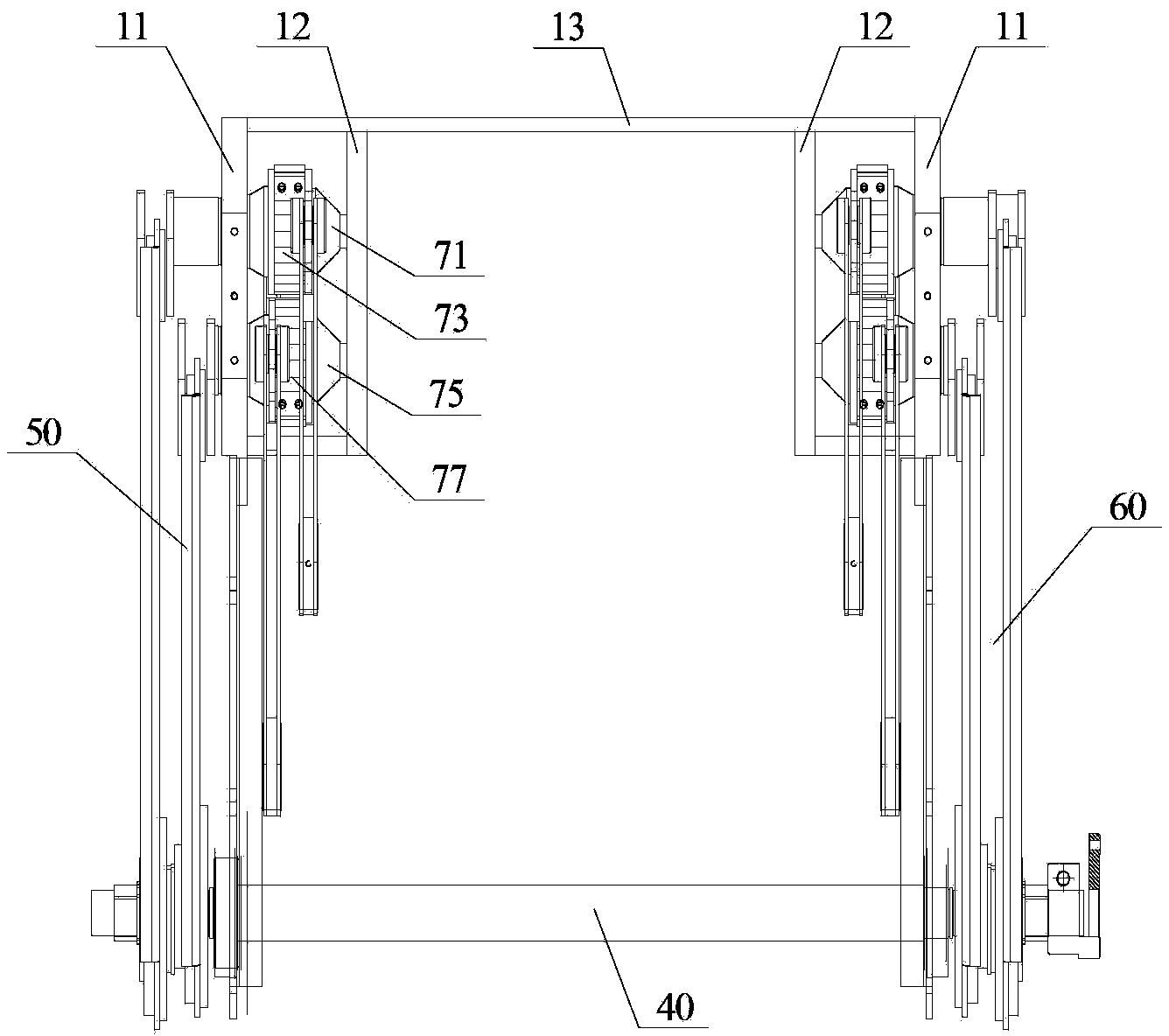

[0020] The present invention is an improvement based on the Chinese invention patent ZL200910135618.8. The main point of improvement lies in the upper knife-lifting drive device, which cancels the upper and lower shafts of the original penetrating design, and uses two sets of left and right knife-lifting drive devices to drive separately. The upper and lower knife lifting devices, so that the middle part of the upper part of the frame is not blocked by the upper shaft and the lower shaft. In this way, when the upper and lower knife lifting devices fail, there is no need to disassemble the upper shaft and the lower shaft, which facilitates maintenance. The present invention will be described in detail below in conjunction with the accompanying drawings.

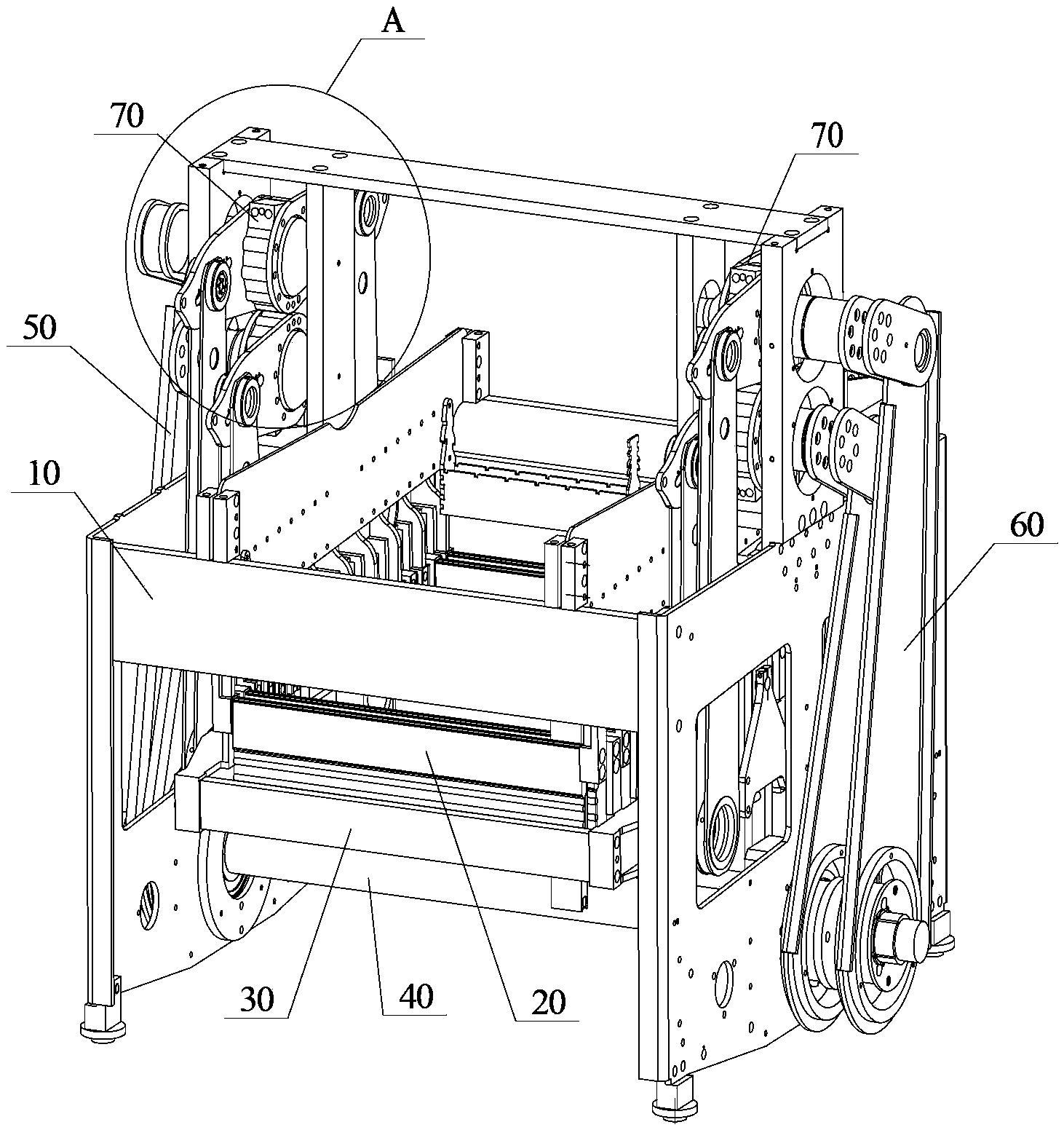

[0021] Such as figure 1 , figure 2 As shown, the computer jacquard machine provided by the present invention includes a frame 10 and upper and lower knife lifting devices 20, 30 arranged in the frame 10, the bottom of the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com