Novel magnetic snap

A magnetic buckle, a new type of technology, is applied in the direction of fasteners, clothing, connecting components, etc., which can solve the problems of inconvenient operation and achieve the effect of convenient operation and tight buckle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

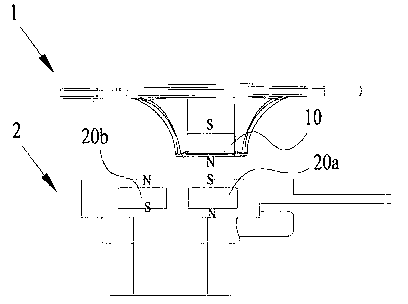

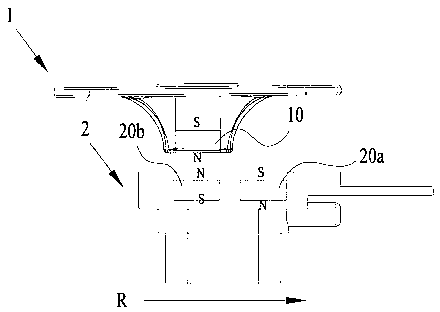

[0037] Embodiment 1 of the present invention provides a new type of magnetic buckle, including a first fastener 1 and a second fastener 2, the first fastener 1 is detachably mounted on the second fastener 2, and the first fastener 1 The first magnetic element 10 is set, and the second magnetic element 20a and the third magnetic element 20b are arranged side by side in the second fastener 2, and the second magnetic element 20a and the third magnetic element 20b can be made parallel to the first magnetic element 10 together. Linear movement, when the second magnetic element 20a is opposite to the first magnetic element 10, the polarity of the opposite surface is opposite to make the first fastener 1 and the second fastener 2 due to the first magnetic element 10 and the second magnetic element 20a Mutual attraction and fastening; when the third magnetic element 20b is opposite to the first magnetic element 10, the polarity of the opposite surface is the same so that the first fast...

Embodiment 2

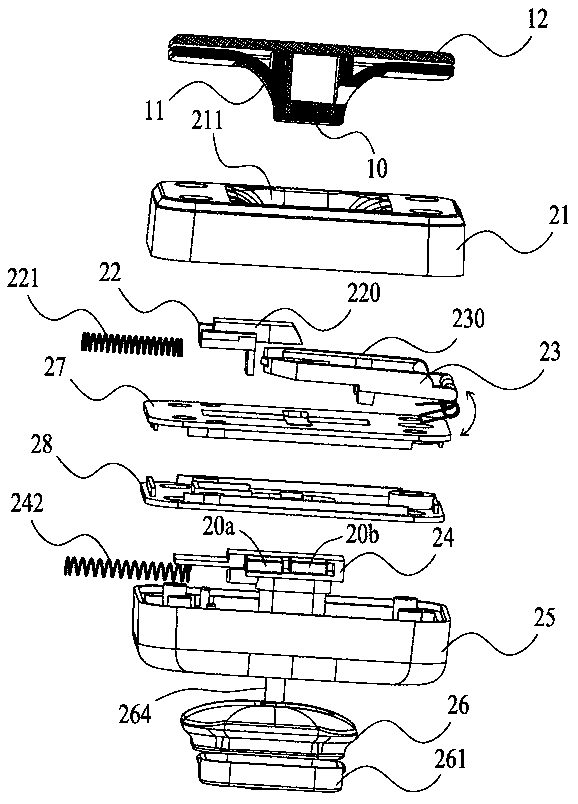

[0040] Compared with Embodiment 1, Embodiment 2 of the present invention provides a new type of magnetic buckle. In addition to utilizing the interaction between the first magnetic element 10 and the second magnetic element 20a and the third magnetic element 20b respectively, it also adds a mechanical structure At the same time, the fastening and separation of the first fastener 1 and the second fastener 2 are realized through the corresponding cooperation of the mechanical structure, which not only enhances the tightness and stability of the fastening, but also further improves the convenience of operation.

[0041] Please refer to image 3 As shown, the embodiment of the present invention provides a novel magnetic buckle, including a first buckle 1 and a second buckle 2 , and the first buckle 1 is detachably installed on the second buckle 2 .

[0042] Please combine Figure 4 As shown, the first fastener 1 includes a cover 12 , a first magnetic element 10 and a male buckle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com