Special efficient data-driven internal-model polynomial controller for industrial processes

An industrial process and data-driven technology, applied in the field of control, can solve problems such as poor control effect, difficult parameter setting of PID controller, and limited adjustment function of PID controller.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

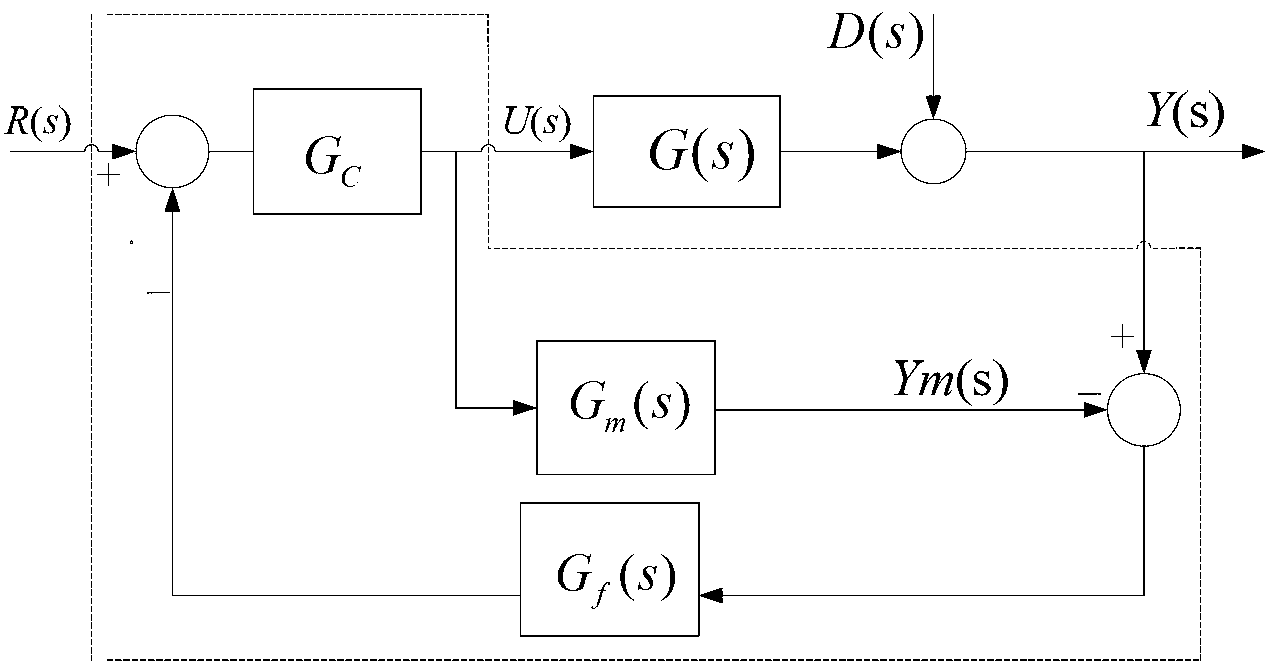

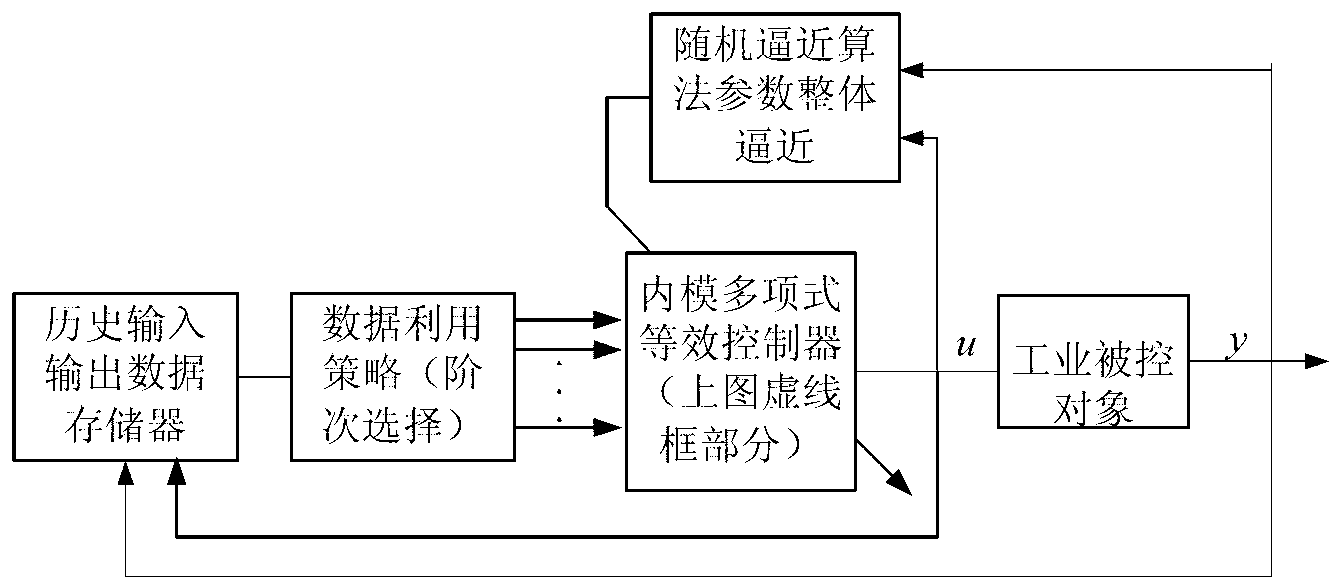

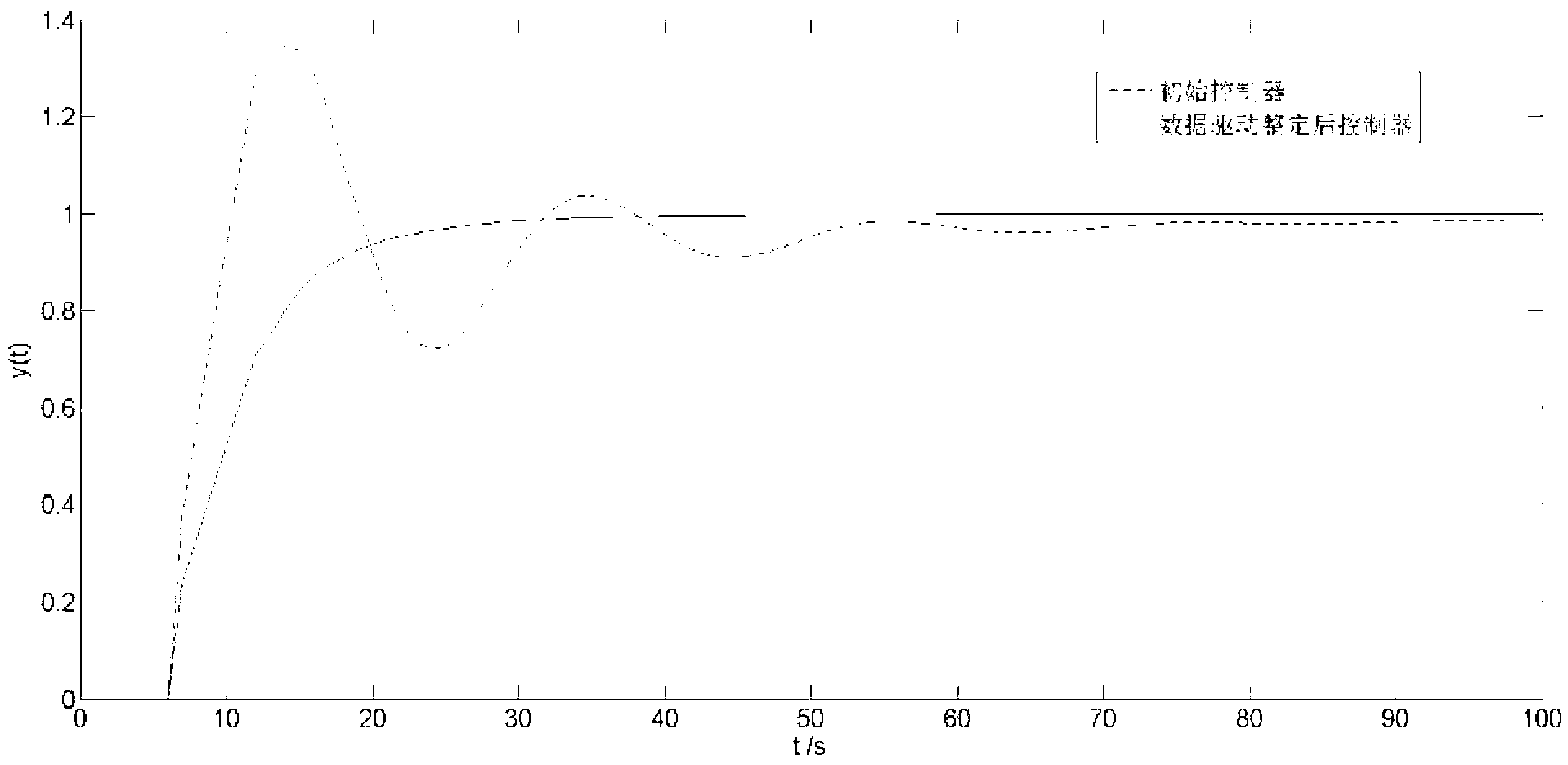

[0036] like figure 1 , figure 2 , image 3 As shown, the present invention is applied to a data-driven internal model polynomial controller in industry, and is characterized in that the control steps are as follows:

[0037] Step 1: Design the overall control structure with polynomial plus internal model function

[0038] The controller with neural network structure has nonlinear characteristics and can handle a class of objects including nonlinear characteristics, but in actual use, the parameters of the neural network are too many, which is not conducive to on-site adjustment. The data utilization strategy of the controller adopting polynomial structure in the present invention should be simple and efficient.

[0039] Take the input of the polynomial controller as the error {e(k)} series, and the output as the {u(k)} series, and its structure is as follows:

[0040] u ( z ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com