Alternating current/direct current motor

An AC/DC and motor technology, applied in electric components, electrical components, electromechanical devices, etc., can solve the problems of inconvenient replacement of carbon brushes or maintenance of motors, increased motor vibration, easy deformation of plastics, etc. Small volume and the effect of reducing temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the embodiments.

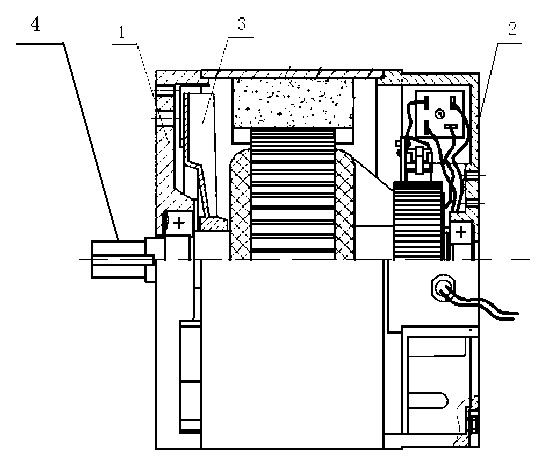

[0009] Such as figure 1 As shown, the AC / DC motor of the present invention includes a frame, a front end cover 1 and a rear end cover 2; the rear end cover 2 is an open structure; the rotor shaft 4 is fixed on the frame; the inner fan blade 3 is installed on the rotor shaft 4. There are at least two inner wind blades 3 .

[0010] Due to the adoption of the open rear end cover, the invention can increase the heat dissipation effect after operation, ensure the heat dissipation capacity and heat dissipation effect of the motor, and reduce the temperature rise inside the motor. At the same time, it is convenient to replace the carbon brush and easy to use. Installing the inner fan blades 3 directly on the rotor shaft 4 can save the volume of the original fan and also r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com