Flameproof thermoplastic resin composition having excellent impact resistance and low gloss characteristics

A thermoplastic resin and composition technology, applied in the field of thermoplastic resin composition, can solve problems such as deterioration and surface gloss reduction, and achieve the effect of excellent impact resistance and low gloss characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 6 and comparative example 1 to 3

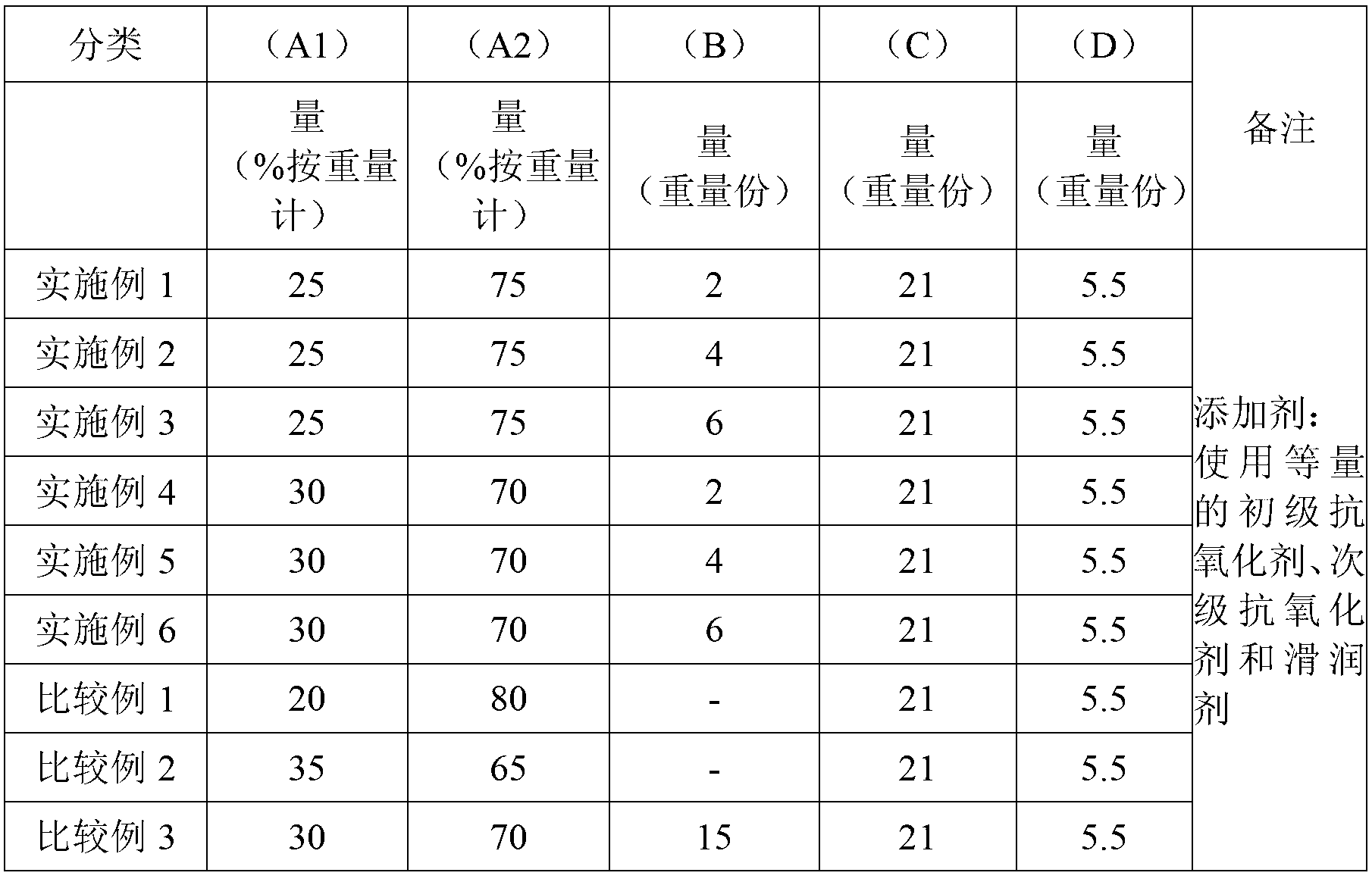

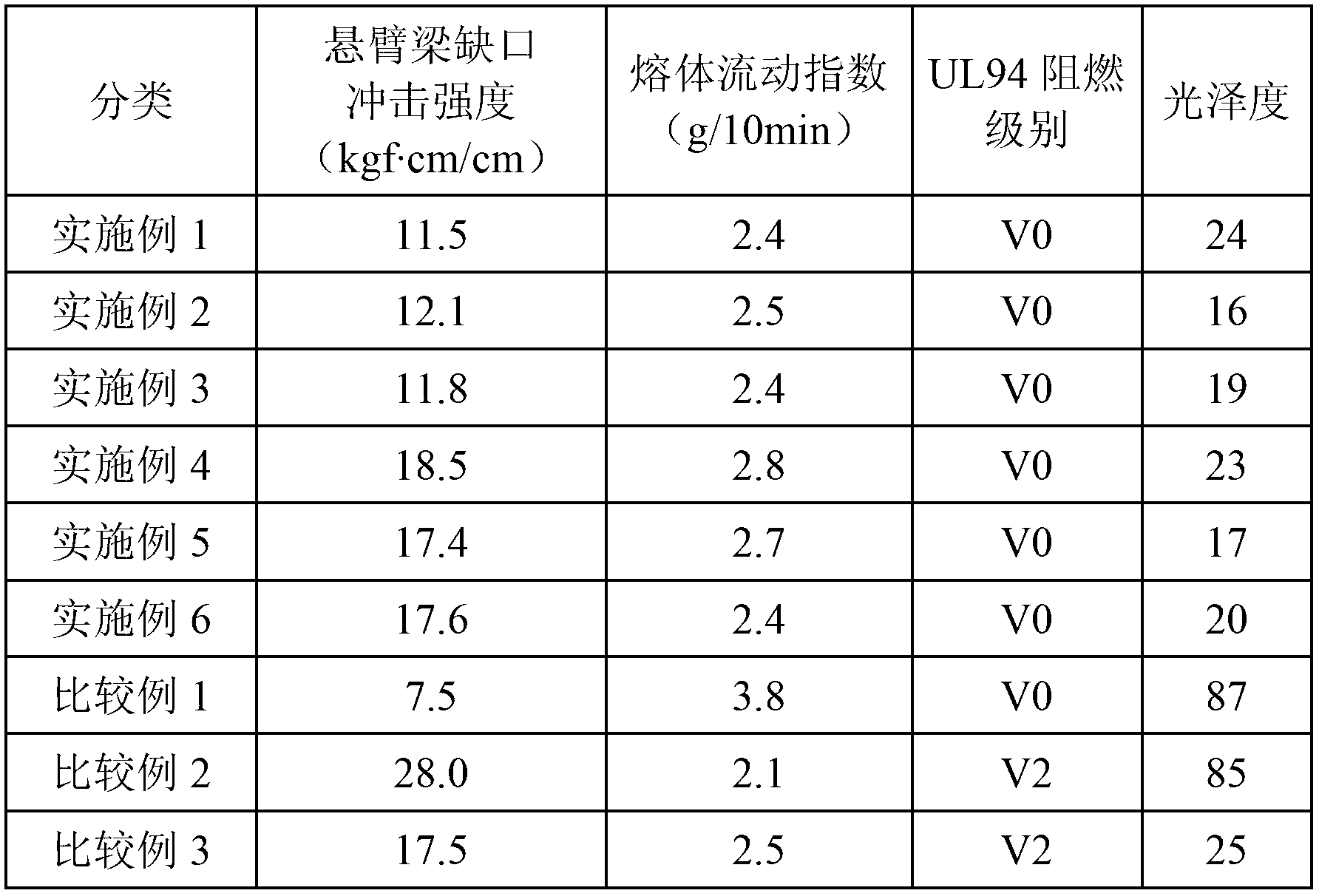

[0088] The above-mentioned ingredients in the amounts shown in Table 1 were added to a Henschel mixer and stirred uniformly for 3 to 10 minutes. The mixture was extruded by a conventional twin-screw extruder at an extrusion temperature of 180 to 210° C., a screw speed of 150 to 300 rpm, and a composition feed rate of 30 to 60 kg / hr to prepare pellets. The prepared pellets were dried at 100° C. for 4 hours, and injection molded using a 6 oz injection molding machine at a molding temperature of 180 to 210° C. and a mold temperature of 40 to 80° C. to prepare samples.

[0089] [Table 1]

[0090]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com