Safe needle guard for butterfly needle group

A technology of butterfly needles and safety needles, which is applied in the field of safety needle covers, and can solve problems such as narrow slots that are too wide, protruding from the needle cover, and infected with viruses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

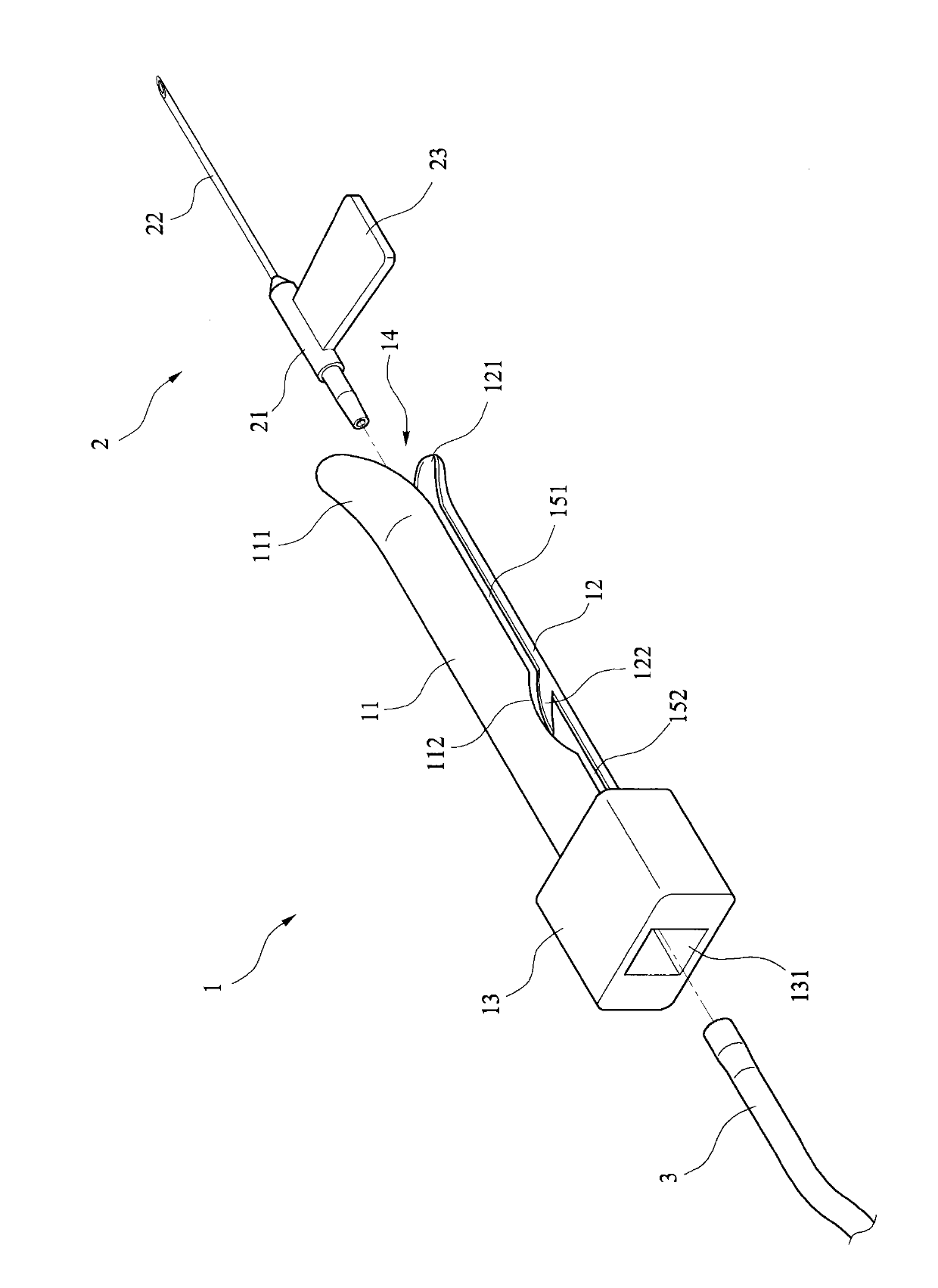

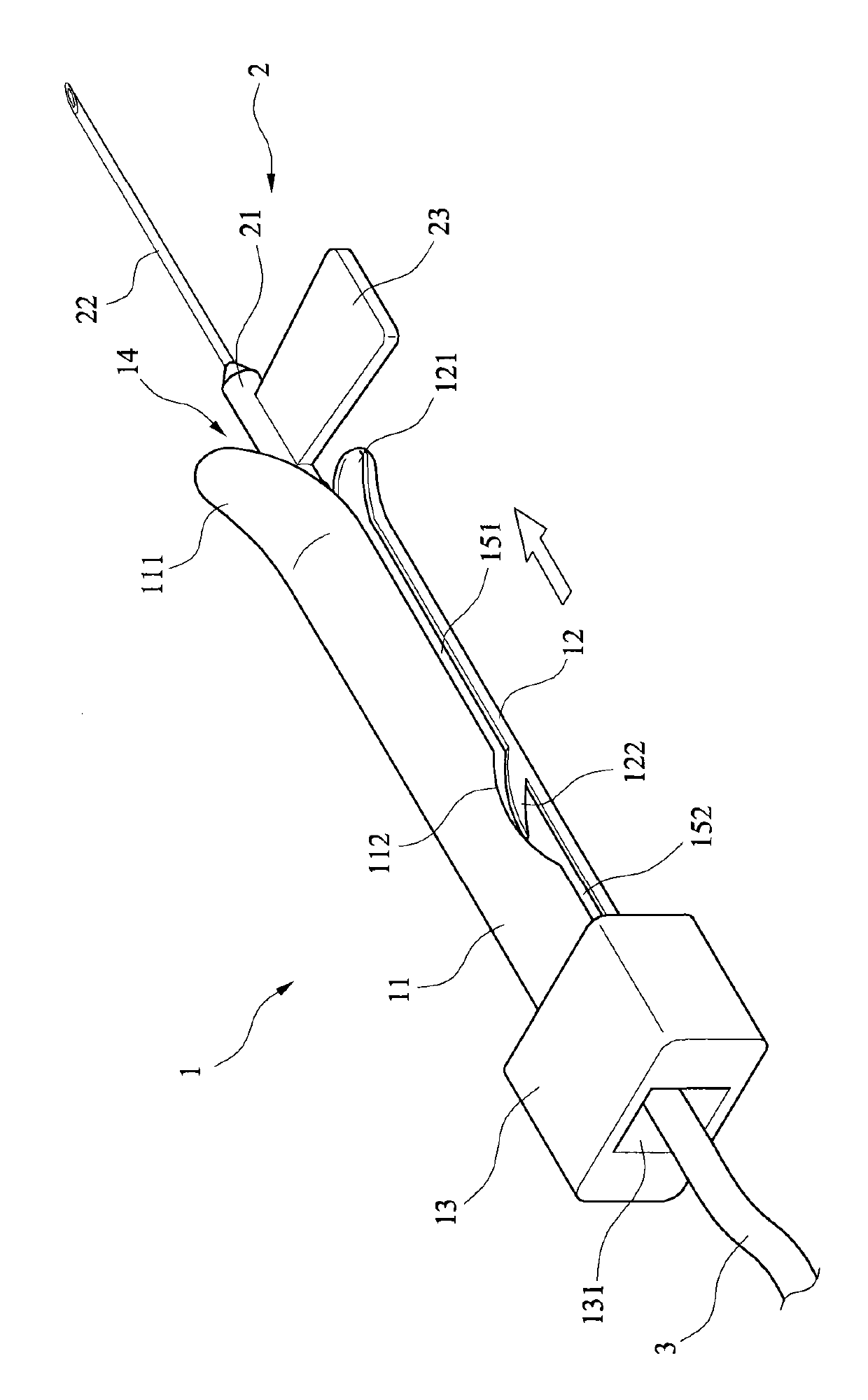

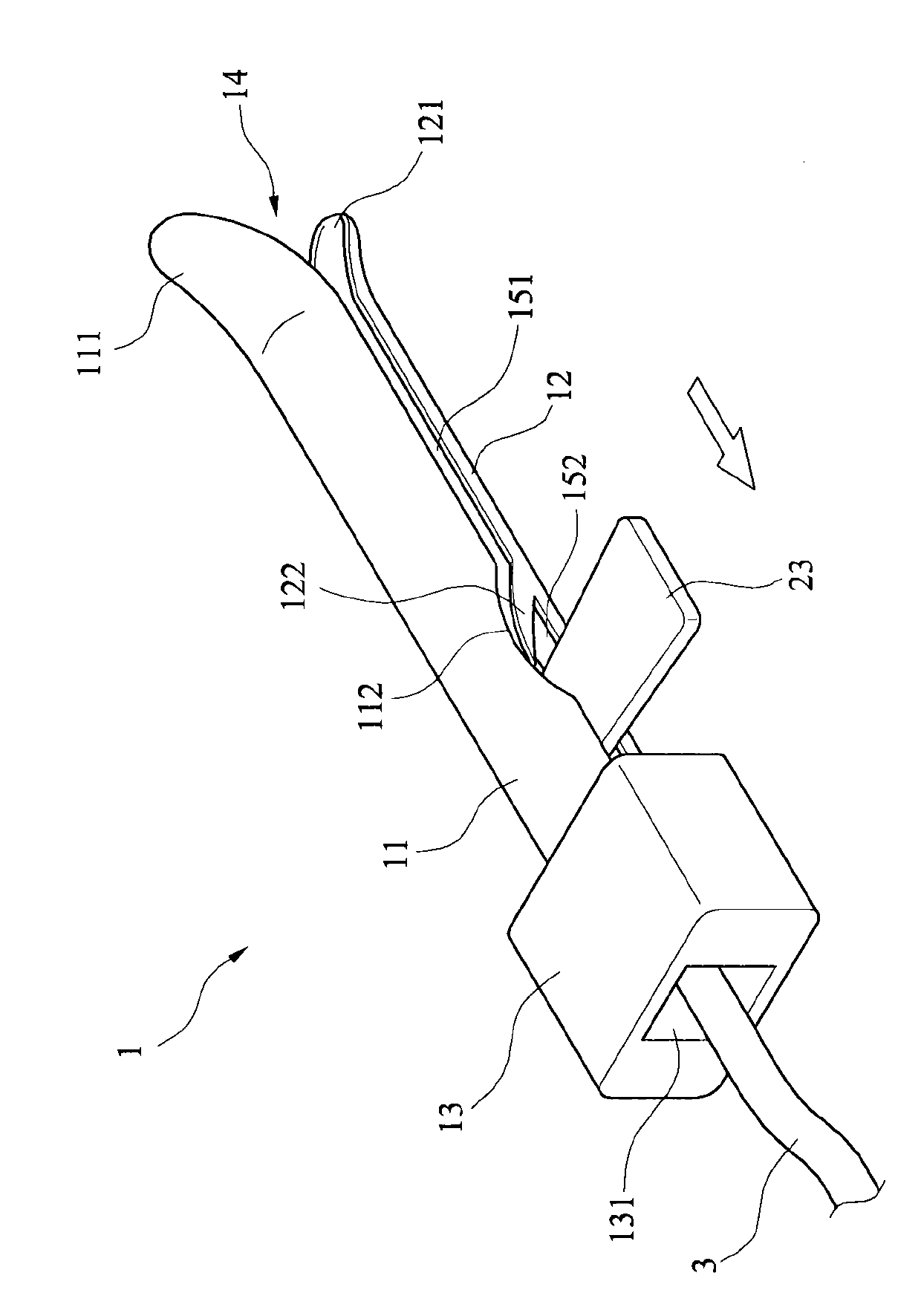

[0024] see figure 1 , which is a perspective view of the first embodiment of the present invention, the safety needle cover 1 is used to fit and protect outside a butterfly needle set 2 . The safety needle sheath 1 of the present invention is basically formed by injection molding of plastic material, especially the joint structure of clips 11, 12 and coupling block 13 described below in the present invention is simple and practical, and is easy to manufacture. The simple structure combined with the action of the elastic gripping force and the clips 11 and 12 achieves the safety and practical characteristics that the safety needle cover should have, and breaks through the technical bottleneck that the complicated structure of the safety needle cover is not easy to manufacture in the past. The following is the description of the present invention. The structural features are described below.

[0025] The safety needle cover 1 has a connecting block 13, a first clip 11 and a sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com