Split-type elbow mold

A split-type elbow technology, applied in the field of split-type elbow molds, can solve the problems of time-consuming and labor-intensive demoulding, and achieve the effect of light weight, easy handling and assembly, and easy demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

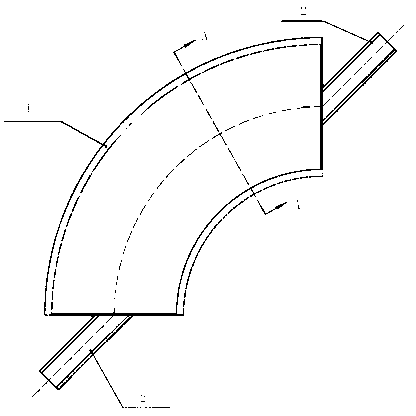

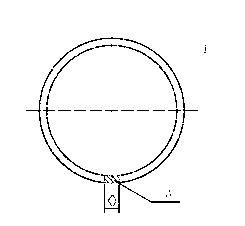

[0016] Such as figure 1 , figure 2 As shown, the traditional FRP elbow mold is an expansive overall structure, including the elbow mold body 1 and the rotating support rod 2. There is an arc seam b=10~20mm wide on the inner arc surface of the elbow mold body 1. Stuff the expansion strips between the seams 3.

[0017] When demolding, first take off the expansion strip 3 in the arc seam, make the mold shrink, and then take off the product.

[0018] Due to the large contact surface between the mold and the product, it is often difficult to demould.

[0019] When the two ends are sockets with larger diameters, the mold of the overall structure cannot be demoulded, and it needs to be molded separately before hand lay-up butt joint.

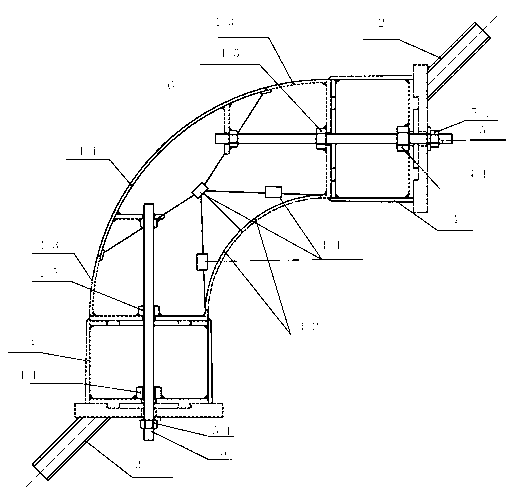

[0020] Such as image 3 As shown, the present invention includes an elbow mold body 1, a rotating support rod 2, and two pieces of mold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com