Diversion type auxiliary plating device and plating method aiming at plating inner surface of hollow plated part

An inner surface, hollow technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve problems such as shortening service life, increasing plating cost, increasing processing difficulty, etc., to reduce difficulty and reduce plating. The amount of liquid is conducive to the effect of uniform plating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Plating of embodiment 1 static tank

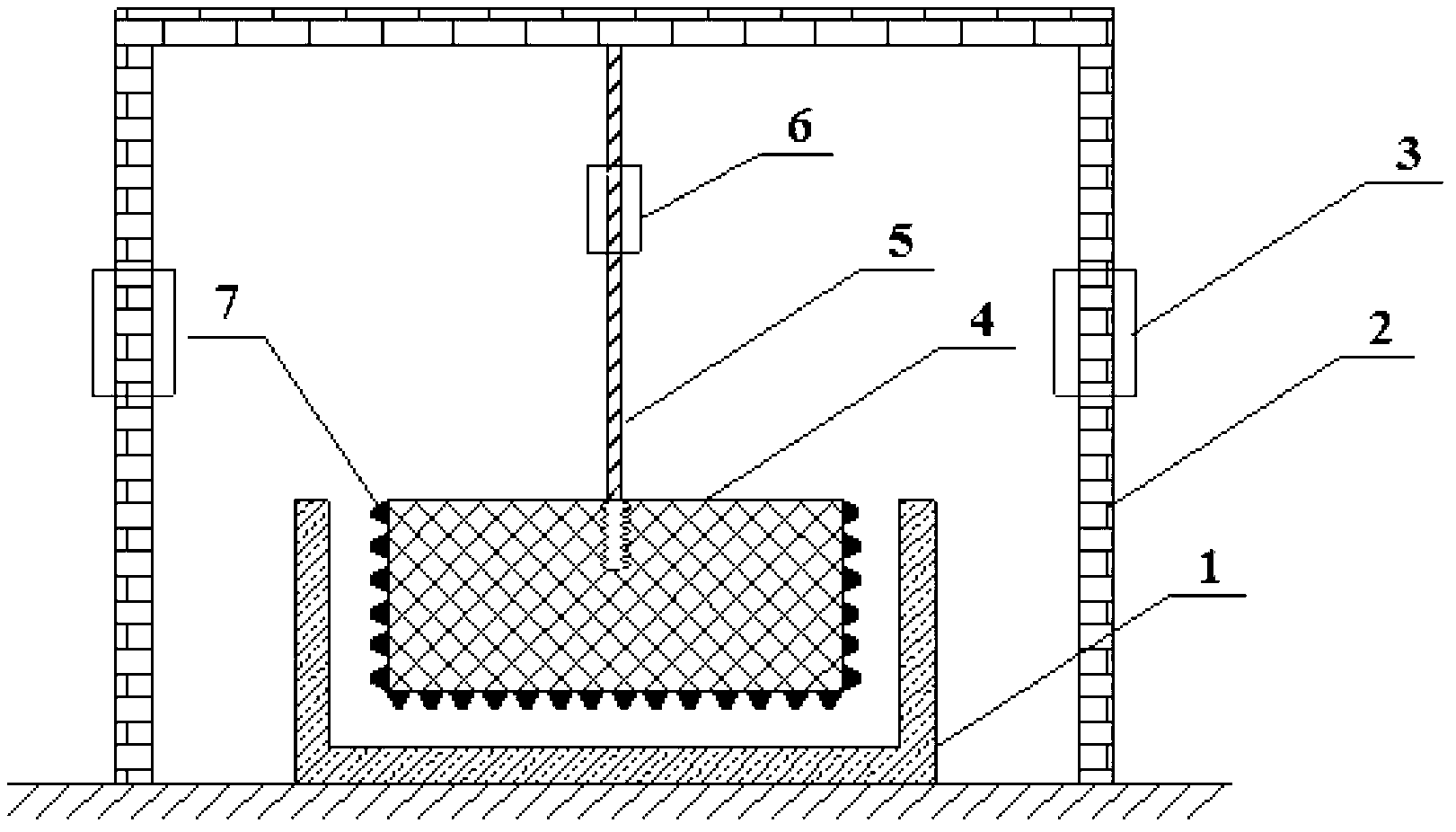

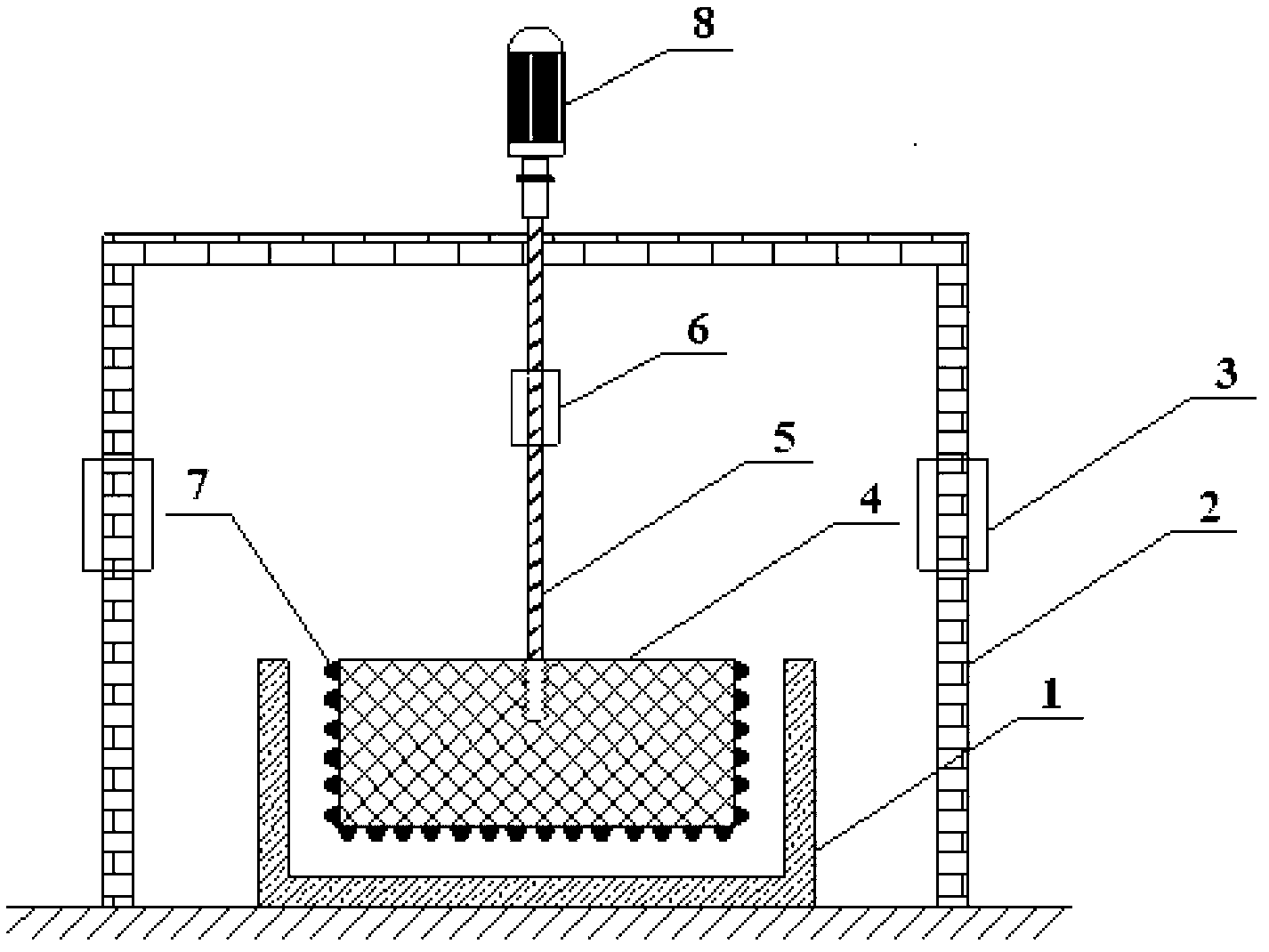

[0024] For the static plating on the inner surface of large tank parts, firstly install the device according to the attached figure 1 Assemble. First, determine the material of the filling part according to the different plating methods, and further select the economical filling part material on the premise of meeting the plating requirements according to the principle of low cost; secondly, according to the shape of the inner space of the hollow plating part Process and shape the appropriate filling piece 4; thirdly, process a semicircular, triangular or trapezoidal discontinuous flow groove design 7 on the surface of the filling piece; fourthly, combine the economical diversion filling piece 4 with the connecting rod Through threaded fixed connection, the economical diversion filler 4 is filled into the inner cavity of the large hollow tank 1, and the height of the connecting rod is adjusted so that the filler is in a suitable po...

Embodiment 2

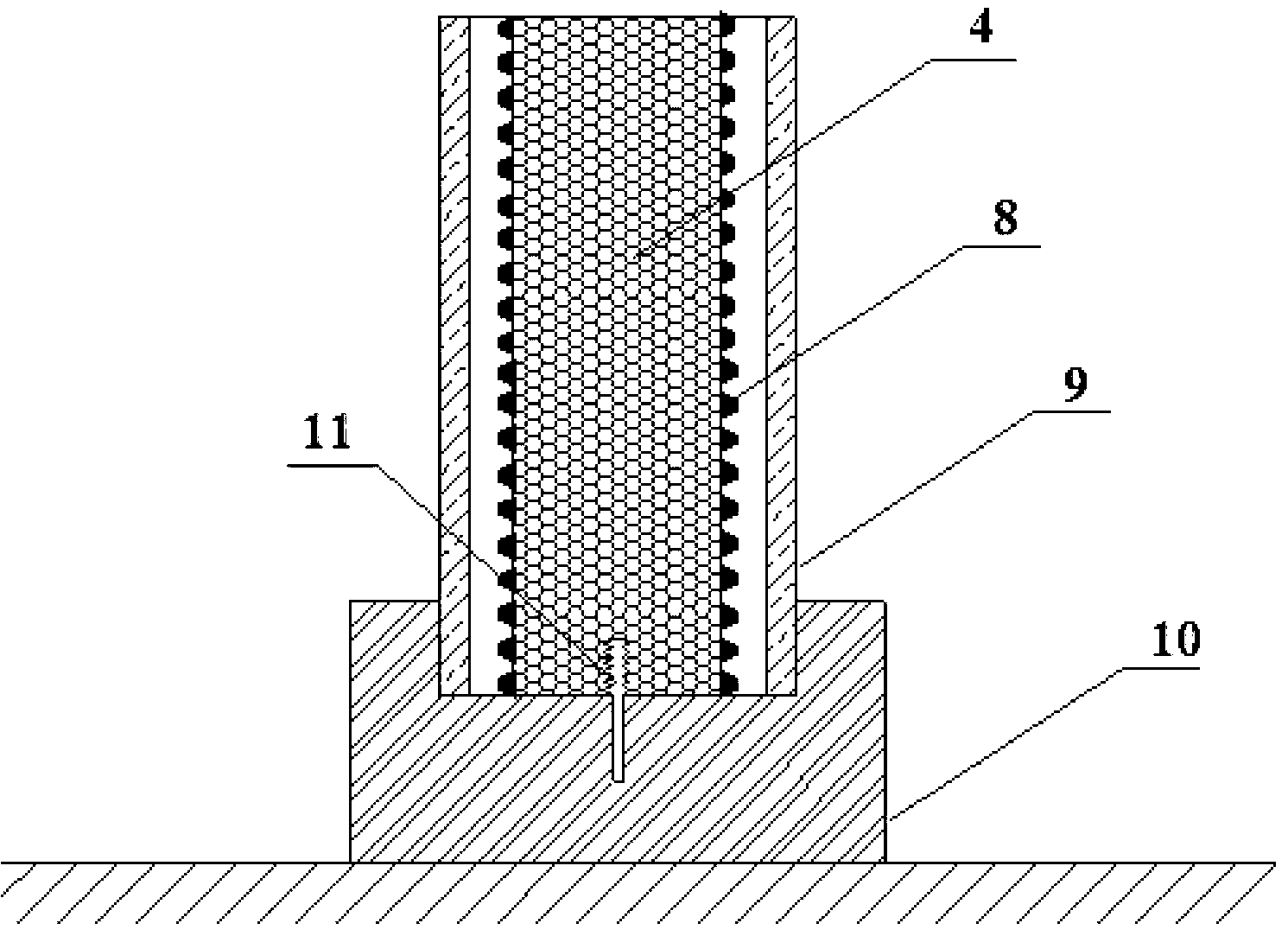

[0025] Embodiment 2 dynamic pipe fittings

[0026] For the static plating on the inner surface of large pipe fittings, first install the device according to the attached Figure 4 Assemble. First, determine the material of the filling part according to the different plating methods, and further select the economical filling part material on the premise of meeting the plating requirements according to the principle of low cost; secondly, according to the shape of the inner space of the hollow plating part Processing and forming suitable fillers 4; third, processing semicircular, triangular or trapezoidal discontinuous flow groove design 7 on the surface of fillers; fourth, filling economical diversion fillers 4 into large hollows The inner cavity of the pipe fitting 9; the 6th, the sealing base 12 of the internal assembly adding plating solution pipeline and the sealing base 13 of the internal assembly discharging plating solution pipeline are respectively installed at two end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com