Combined opener

A technology of opening machine and opening device, which is applied in fiber opening and cleaning machines, fiber opening and cleaning, textiles and papermaking, etc. It can solve the problems of large manpower and material resources, low production efficiency, and unsatisfactory one-time opening effect of fibers. Achieve the effect of accurate electrification control, increase production and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

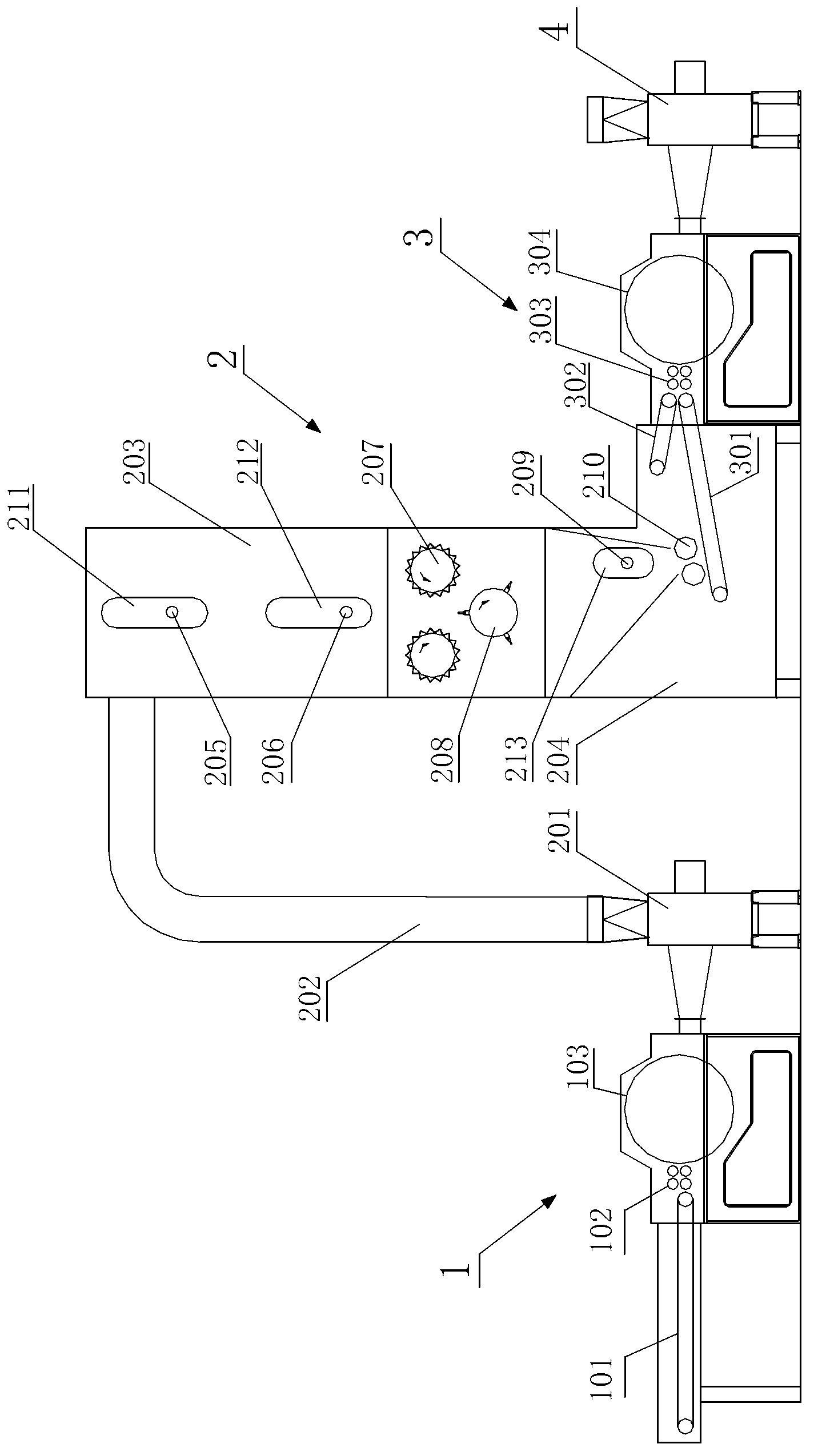

[0013] combine figure 1 As shown, a combined opening machine includes a front opening device 1, a fiber conveying device 2 and a rear opening device 3, the fiber conveying device is located between the front opening device and the rear opening device, and the three devices are connected in sequence.

[0014] The front opening device 1 comprises a flat curtain 101, a double feeding roller 102 is arranged behind the flat curtain, and an opening cylinder 103 is arranged immediately behind the double feeding roller.

[0015] The fiber conveying device 2 includes a first conveying fan 201 , a feeding box is arranged behind the first conveying fan, and the first conveying fan and the feeding box are connected through a conveying pipeline 202 . The feeding box is composed of an upper volume box 203 and a lower volume box 204. A pair of first photoelec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com