Bed of sewing machine

A sewing machine and machine technology, applied in sewing machine components, sewing equipment, textiles and papermaking, etc., can solve the problems of occupying space, inconvenient installation of sewing machines, and wasting time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described below in conjunction with accompanying drawing.

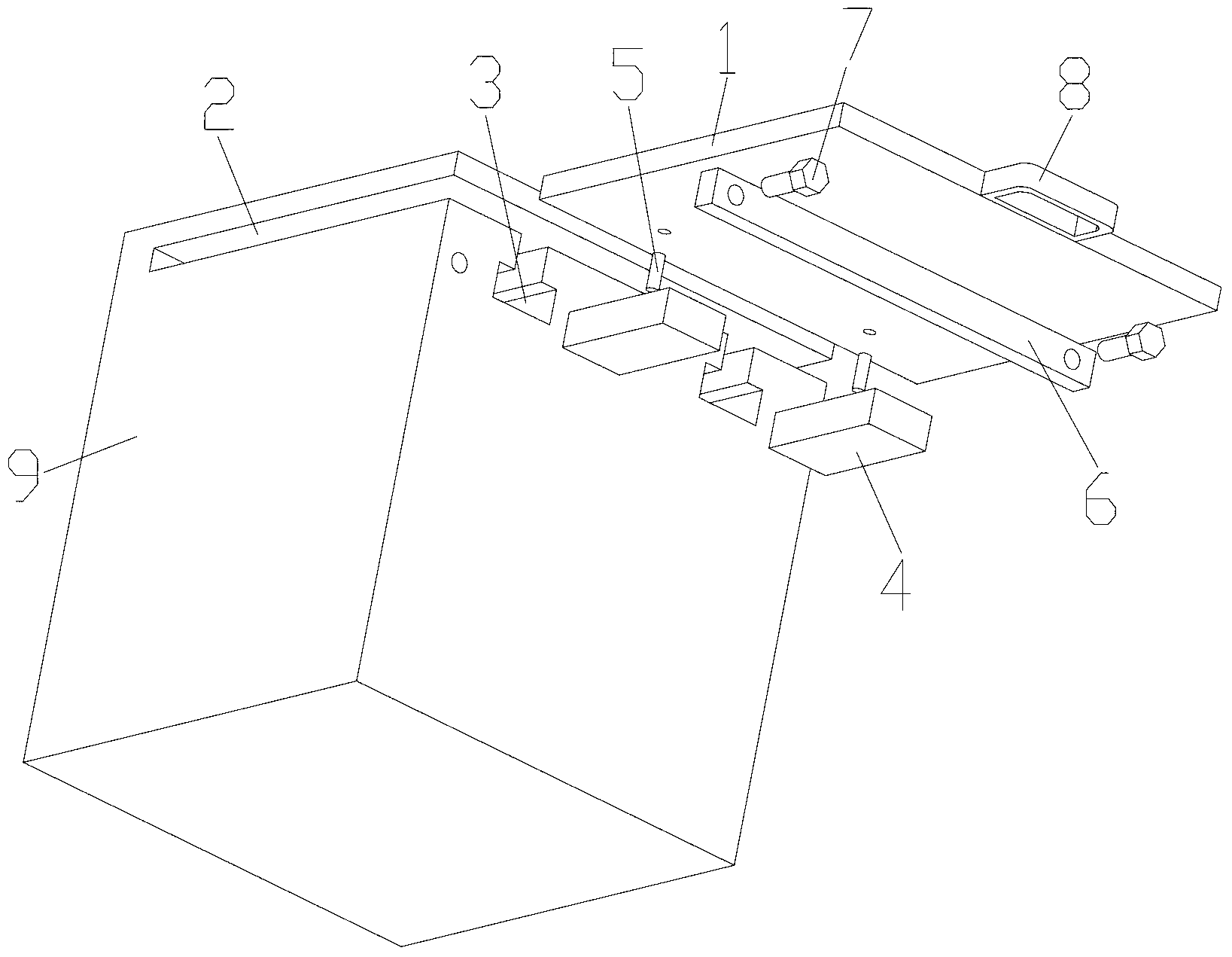

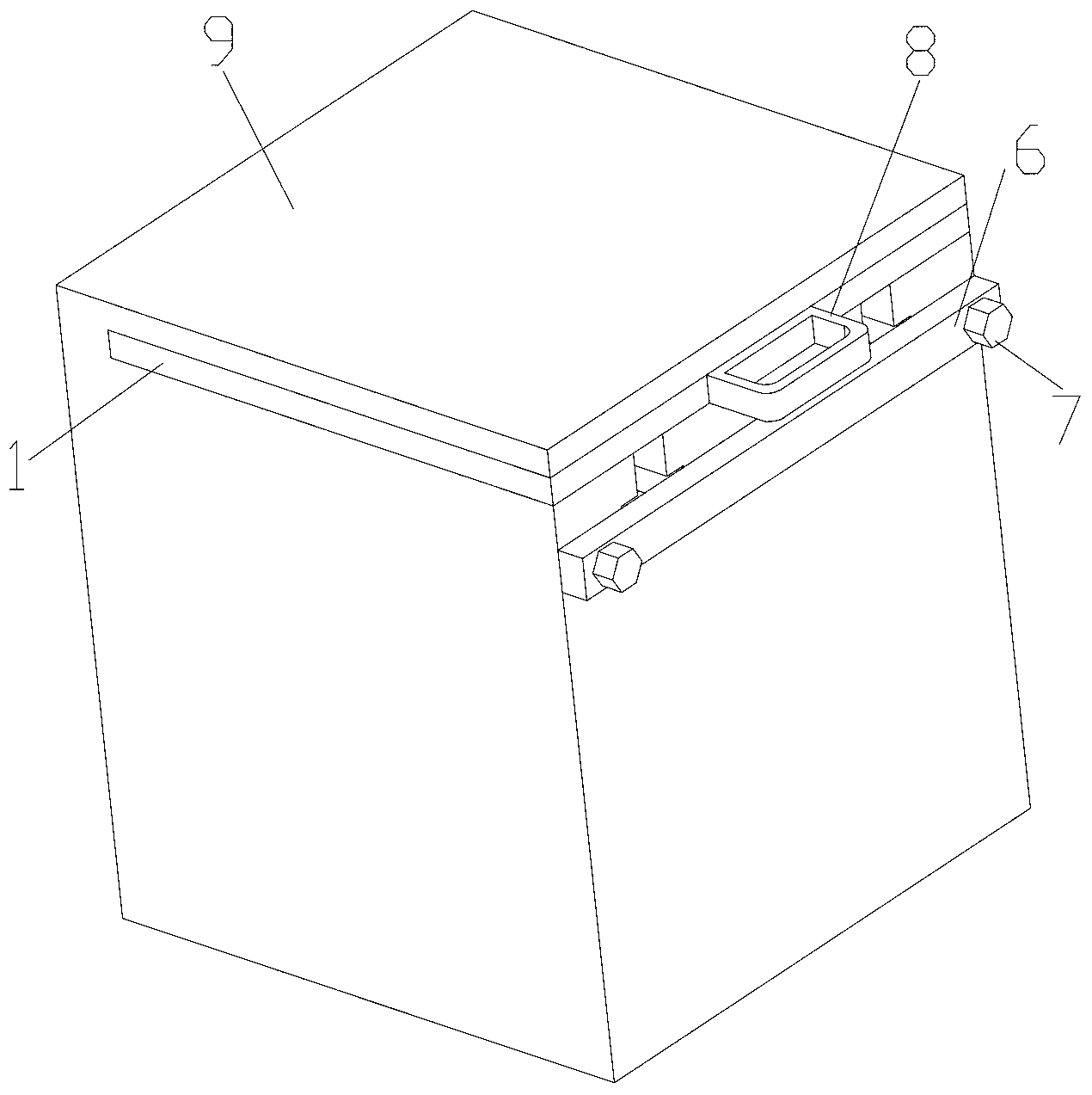

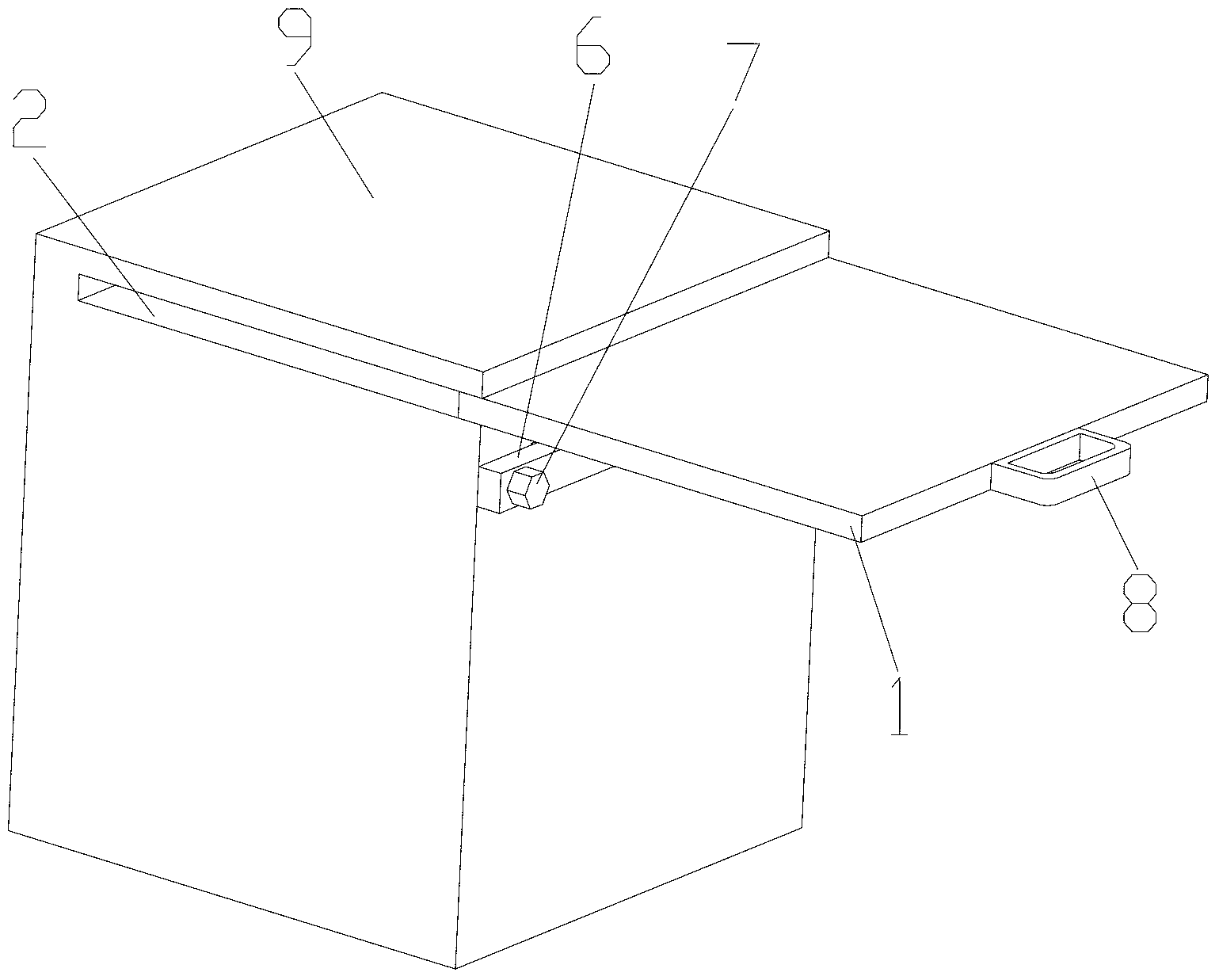

[0018] as attached figure 1 The shown sewing machine table of the present invention includes a machine table 9, a plug plate 1, a sliding device and a limiting device; a slot 2 is provided on the table; a positioning slot is provided below the slot 2. Slot 3; said slot 2 is provided with a plugboard 1; said plugboard 1 is movably fixed on the machine table 9 through a sliding device and a positioning groove 3; said positioning groove 3 is provided with a limiting device; said The sliding device includes a slider 4 and a connecting column 5; the limiting device includes a baffle 6 and a locking screw 7; the positioning groove 3 is an inverted "T" groove; the plugboard 1 is also provided with a handle 8 .

[0019] as attached Figure 2-3 In the sewing machine platform described in the present invention, the flashboard 1 is fixedly connected to the slider 4 through the positioning colum...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap